Preparation method of chitosan monomolecular layer film

A chitosan single and molecular layer technology, applied in the field of biofilm preparation, can solve the problem of insufficient uniformity of the film, and achieve the effect of improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific implementations.

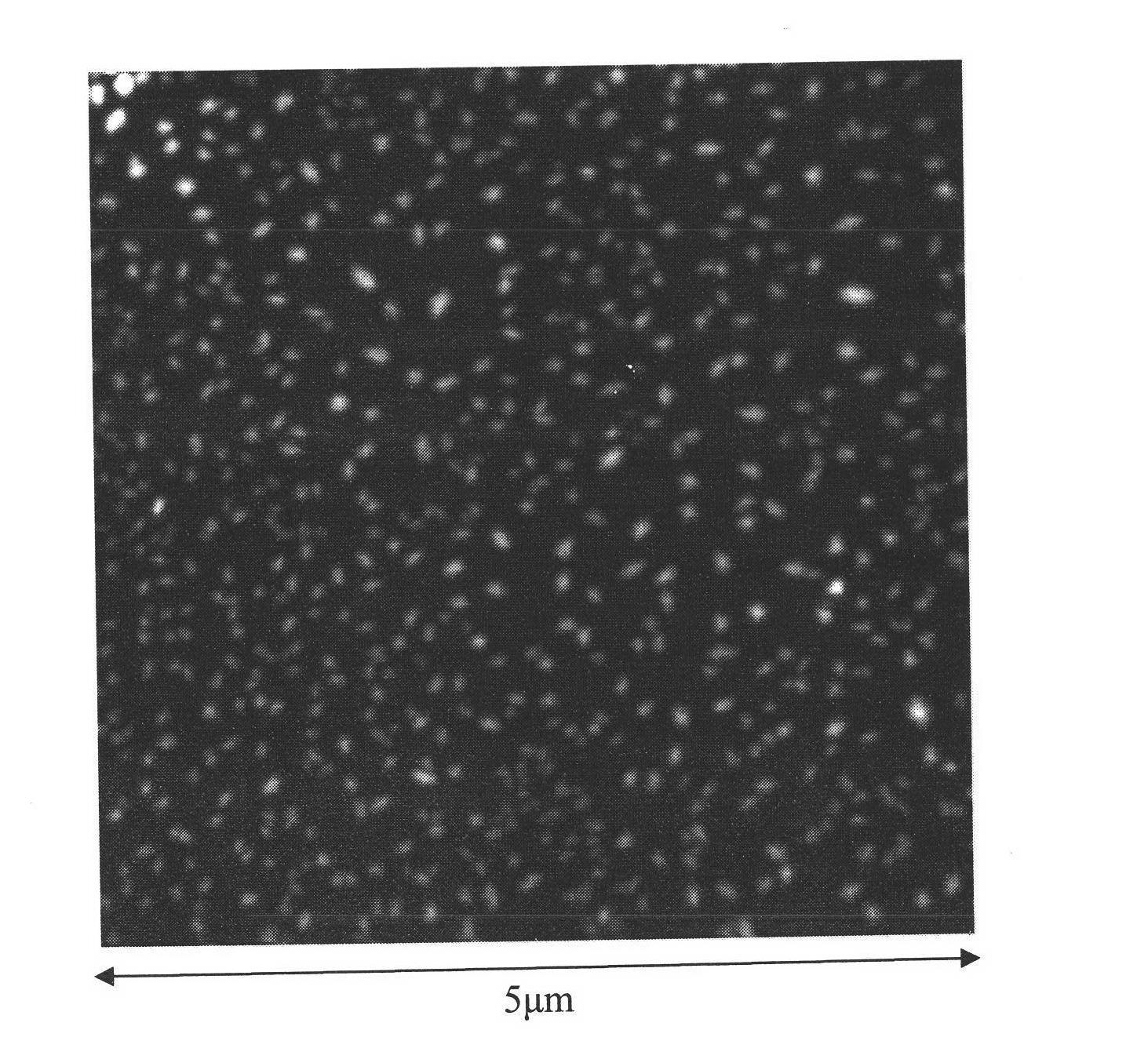

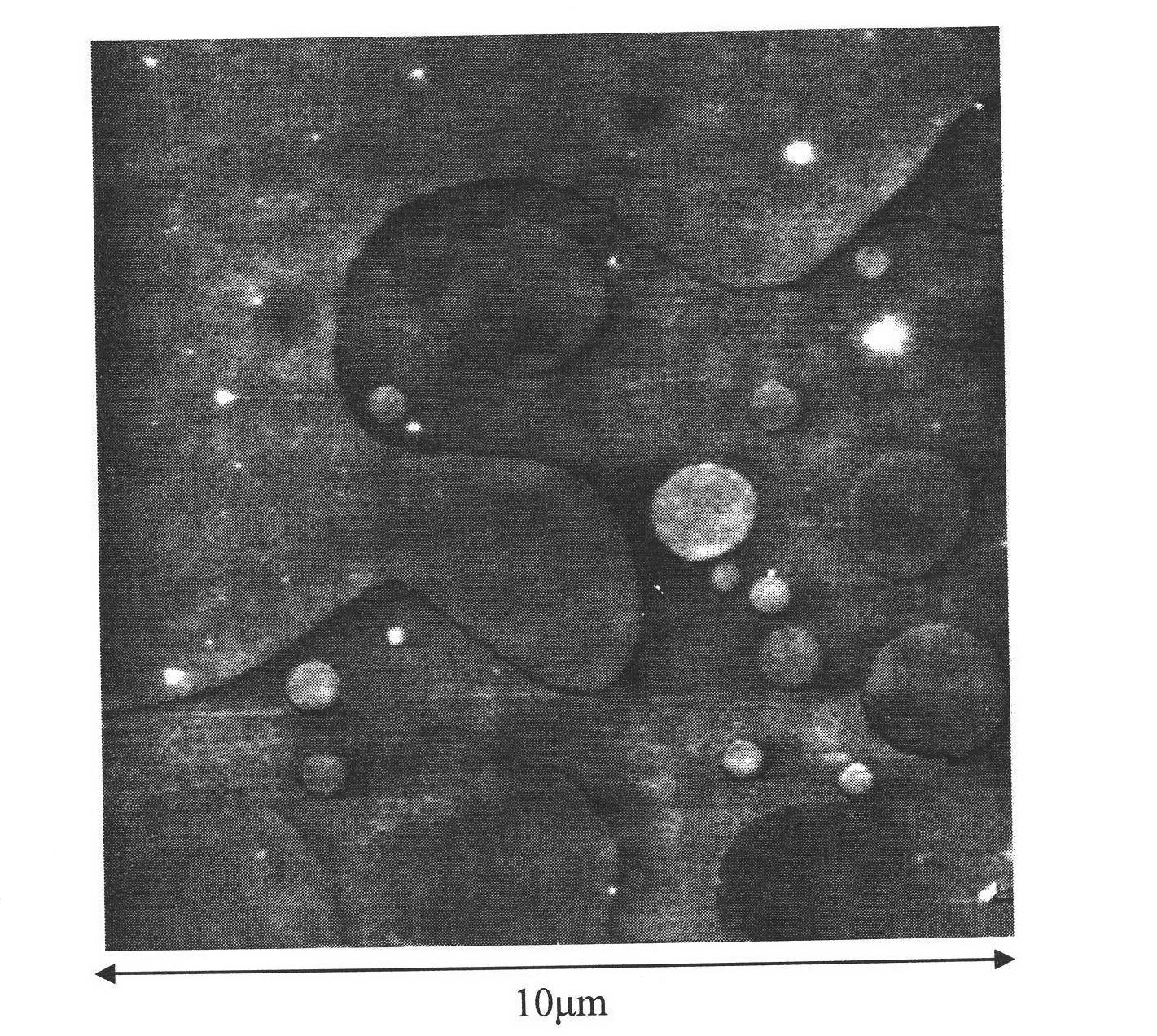

[0023] The invention aims at a series of problems faced in the preparation of the chitosan film in the prior art, such as large film thickness and high roughness. A new method for preparing chitosan monolayer films is proposed. This method can not only ensure the monolayer properties of the film, but also keep chitosan molecules in the form of films at the nanometer level. foundation for further research in the field.

[0024] Atomic Force Microscope (AFM) is a high-resolution scanning probe microscope. It is a microscope designed to capture three-dimensional images at high speed based on the principle of scanning tunneling microscope. It usually includes a probe, an electronic control system, and a computer processing system. And photoelectric dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com