Zirconium-phosphate-based luminescent material, preparation method thereof, and application thereof

A luminescent material, zirconium phosphate technology, applied in the field of fluorescent materials, can solve the problems of poor color purity, poor chemical stability, low luminous efficiency, etc., and achieve the effects of adjustable luminous intensity, high luminous intensity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] According to the chemical formula Sr 7 Zr(PO 4 ) 6 The stoichiometric ratio of each element in the SrCO 3 : 5.1671 g, ZrO 2 : 0.6161 g, NH 4 h 2 PO 4 : 3.451 g. Grind in an agate mortar and mix well. The uniformly mixed powder was calcined for the first time in an air atmosphere at a temperature of 350°C, kept for 2 hours, cooled to room temperature naturally, and then the samples were taken out. The powder calcined for the first time was fully ground again in an agate mortar, and the second sintering was carried out under an air atmosphere at a temperature of 1000 ° C, kept for 5 hours, and naturally cooled to room temperature. The previous process was repeated, and the final sintering was carried out again at a temperature of 1300° C., kept for 8 hours, and naturally cooled to room temperature to obtain the final target product.

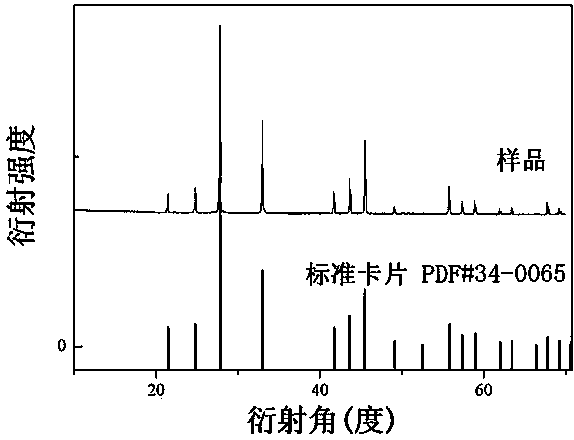

[0042] figure 1 For the Sr prepared in this example 7 Zr(PO 4 ) 6 Comparison of the X-ray powder diffraction pattern of t...

Embodiment 2

[0045] According to the chemical formula Sr 6.65 Eu 0.35 Zr(PO 4 ) 6 The stoichiometric ratio of each element in the 2 o 3 : 0.308 g, SrCO 3 : 4.909 g, ZrO 2 : 0.6161 g, NH 4 h 2 PO 4 : 3.451 g. Grind in an agate mortar and mix well. The homogeneously mixed powder is calcined for the first time in an air atmosphere at a temperature of 350°C, kept for 2-10 hours, and the sample is taken out after cooling down to room temperature naturally. The powder calcined for the first time is fully ground again in an agate mortar, and the second sintering is carried out under an air atmosphere at a temperature of 1000 ° C, kept for 2-10 hours, and naturally cooled to room temperature. Repeat the previous process and carry out the final sintering again at a temperature of 1300°C, keep warm for 3~10h, and cool naturally to room temperature to obtain the final target product.

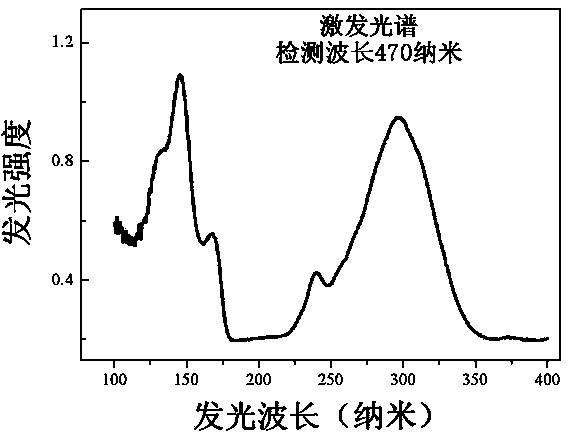

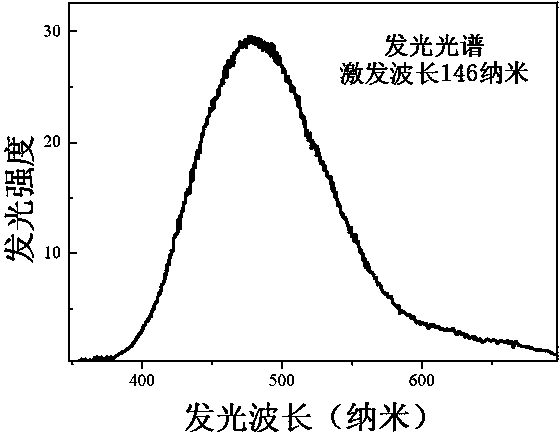

[0046] Figure 4 For the Sr prepared in this example 6.65 Eu 0.35 Zr(PO 4 ) 6 Excitation and emiss...

Embodiment 3

[0048] According to the chemical formula Sr 6.65 Eu 0.35 Zr(PO 4 ) 6 The stoichiometric ratio of each element in the 2 o 3 : 1.232 g, SrCO 3 : 4.134 g, ZrO 2 : 0.6161 g, NH 4 h 2 PO 4 : 3.451 g. Grind in an agate mortar and mix well. The homogeneously mixed powder is calcined for the first time in an air atmosphere at a temperature of 350°C, kept for 2-10 hours, and the sample is taken out after cooling down to room temperature naturally. The powder calcined for the first time is fully ground again in an agate mortar, and the second sintering is carried out under an air atmosphere at a temperature of 1000 ° C, kept for 2~10 hours, and naturally cooled to room temperature. Repeat the previous process and carry out the final sintering again at a temperature of 1300°C, keep warm for 3~10h, and cool naturally to room temperature to obtain the final target product.

[0049] Figure 5 For the Sr prepared in this example 5.6 Eu 1.4 Zr(PO 4 ) 6 Excitation and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com