Hot board drying machine for heating high-property fibers

A high-performance fiber and dryer technology, applied in textiles and papermaking, etc., can solve the problems of poor product effect and failure to meet the heating needs of high-performance fibers, and achieve the effect of meeting heating requirements, good heating effect, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

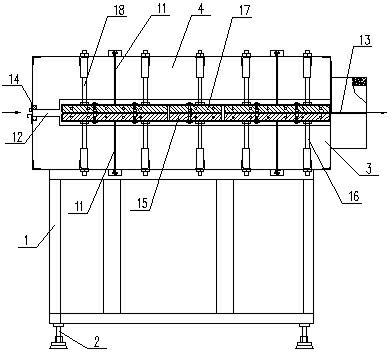

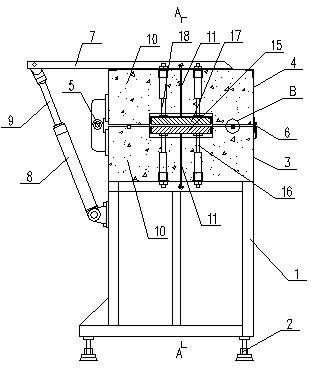

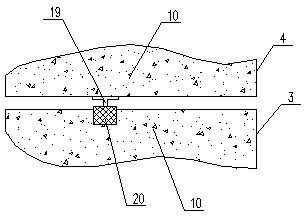

[0011] Such as figure 1 , figure 2 As shown, the hot plate dryer for high-performance fiber heating includes: a frame 1, the frame 1 is supported on the ground by a number of support feet 2, and a lower heating box 3 that cooperates with each other is arranged on the frame 1. Upper heating box 4, the left side of lower heating box 3 and upper heating box 4 are connected by hinge 5, the right side of lower heating box 3 and upper heating box 4 is connected by latch 6, and the upper end of upper heating box 4 is connected with connecting bracket 7 and The piston rod 9 of the cylinder 8 is connected, the cylinder 8 is fixed on the frame 1, and the aluminum silicate cotton 10 and the thermocouple 11 are arranged in the lower heating box 3 and the upper heating box 4 respectively, and the lower heating box 3 and the upper...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap