Metal accessory protectant for dyeing and processing garment and application thereof

A technology of protective agent and metal corrosion inhibitor, which is applied in the field of protective agent composition of metal auxiliary materials for garment printing and dyeing processing, can solve the problems of high labor cost, complicated operation, and difficulty in ensuring that the metal corrosion inhibitor covers the entire surface, so as to improve production Efficiency, anti-darkening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1: Preparation of metal auxiliary material protective agent composition of the present invention

[0091] 8 grams of lauric acid diethanolamide phosphate and 12 grams of lauryl betaine are gently heated and dissolved, and then 80 grams of water are added under stirring to obtain 100 grams of metal auxiliary material protective agent (1) of the present invention, which is a transparent solution.

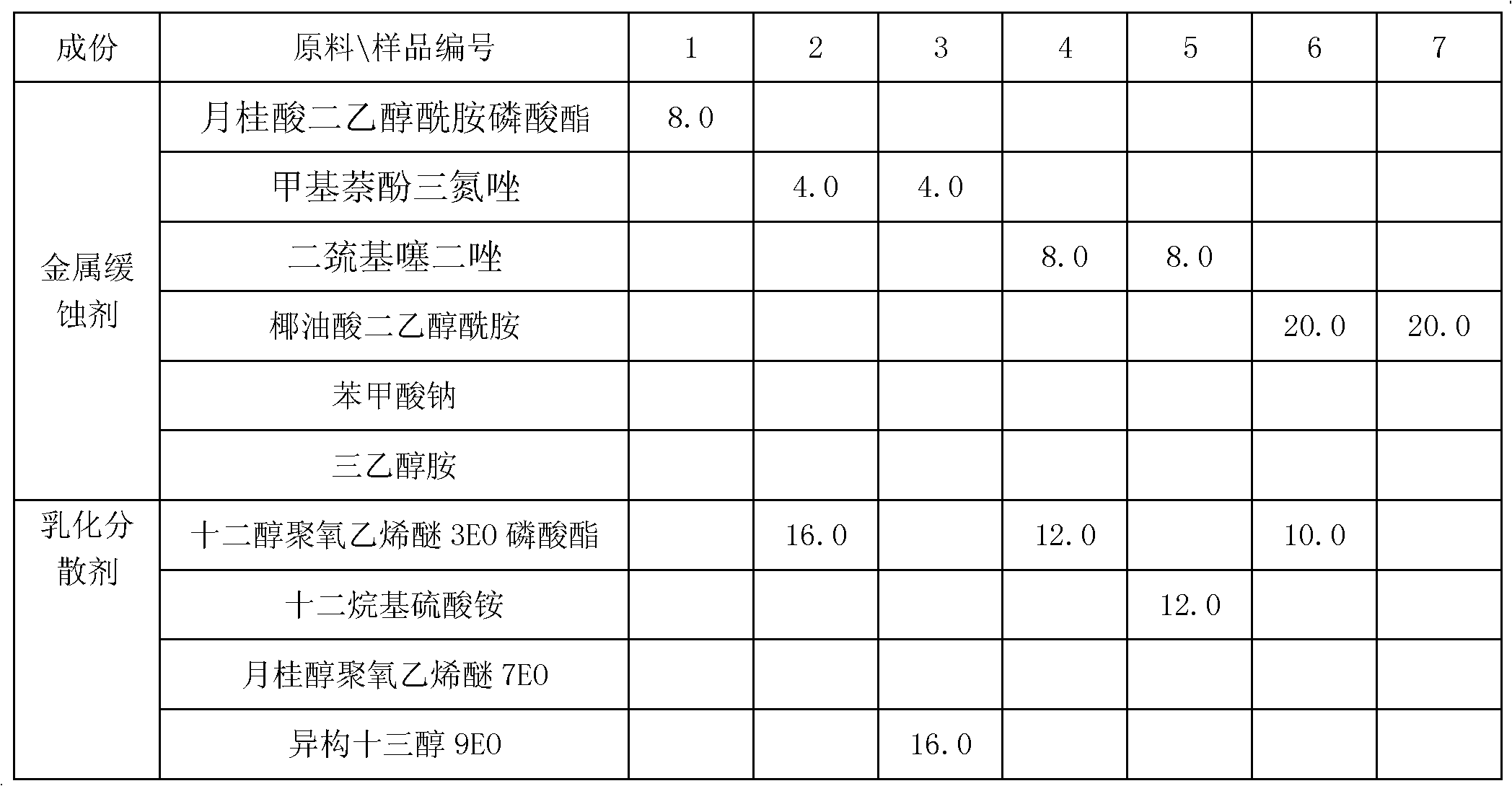

Embodiment 2-20

[0093] According to the components and dosage shown in Table 1 below, first mix the metal corrosion inhibitor and emulsifying dispersant, then heat and stir properly to dissolve the solid material completely, then add water, and finally add the chelating dispersant Stir and mix with the solubilizing agent to obtain 100 grams of the protective agent for metal auxiliary materials (2-20) of the present invention, each of which is a transparent solution.

[0094] Table 1: (each component is in grams).

[0095]

[0096]

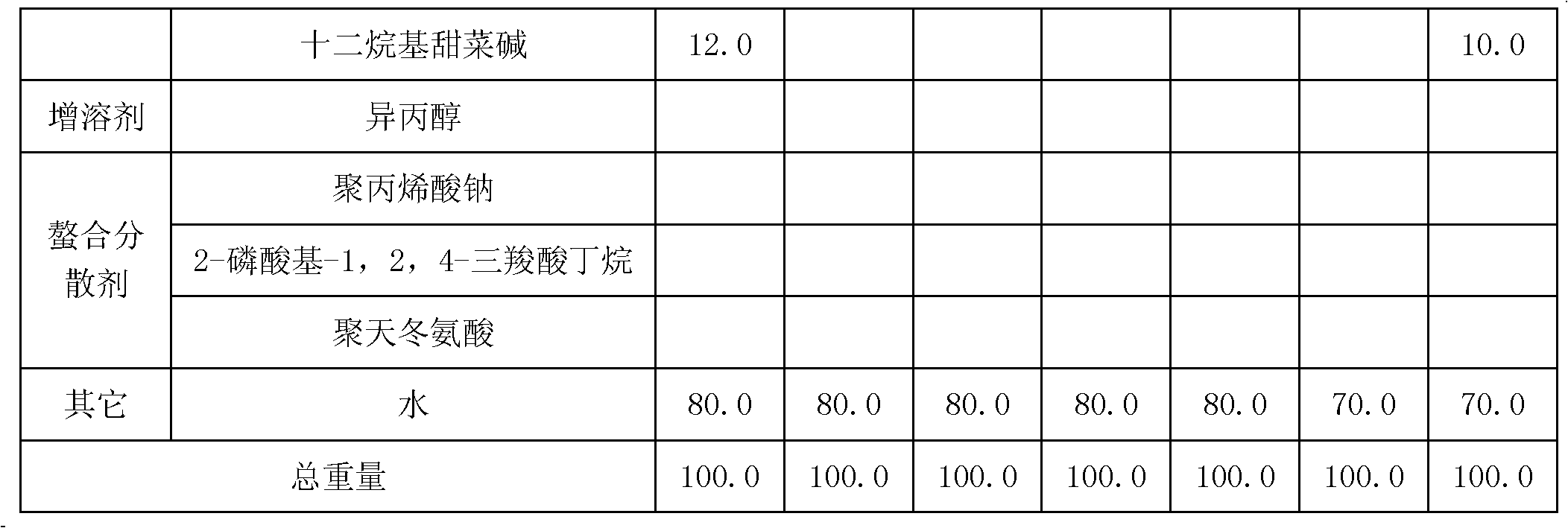

[0097] Table 1 - continued

[0098]

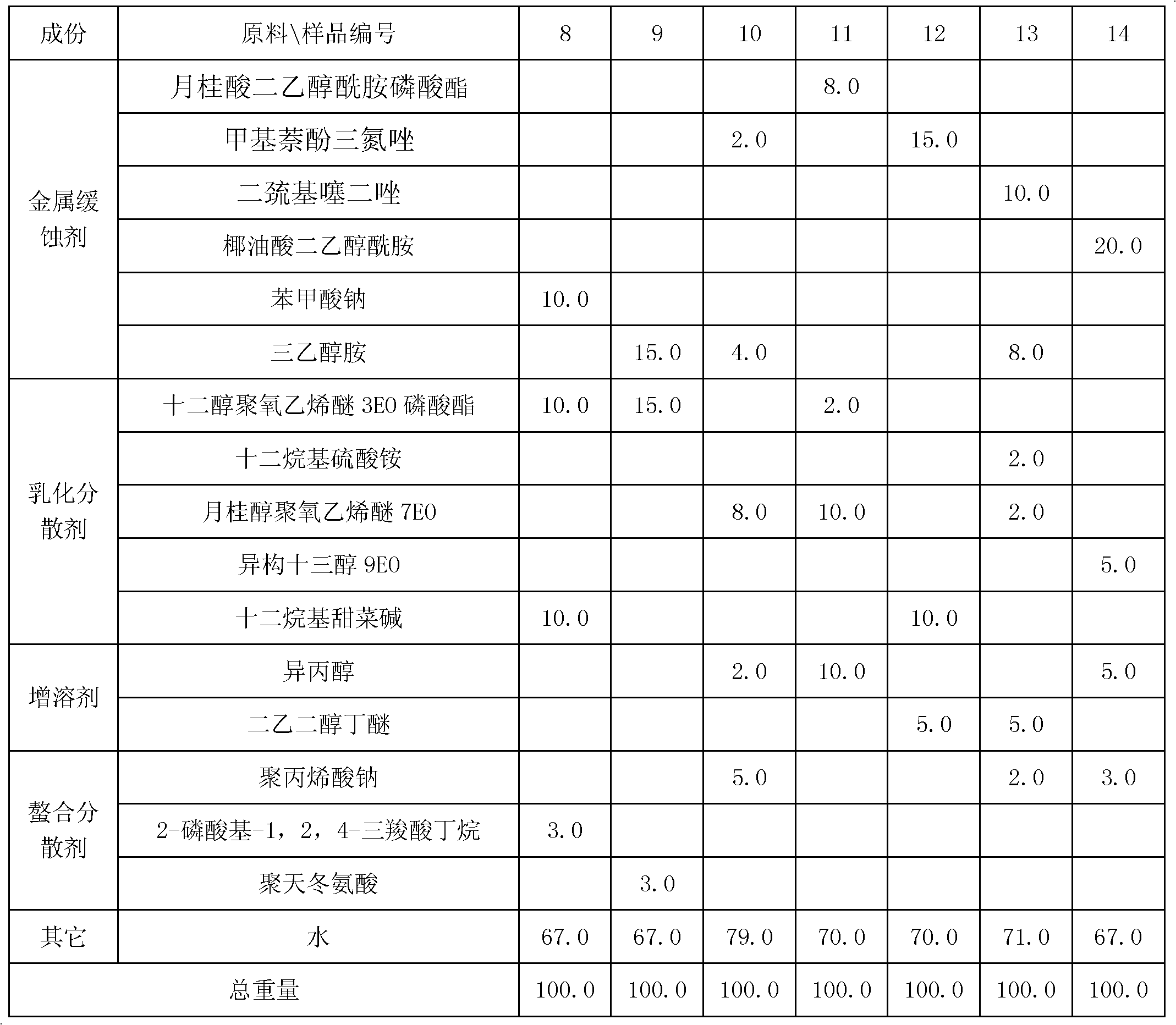

[0099] Table 1 - continued

[0100]

[0101] Application of protective agent for metal auxiliary materials

[0102] 1) Pretreatment process

[0103] Fabric: Pure cotton khaki gray cloth 20g

[0104] Zipper: No. 5 brass zipper with a length of 5cm, and aluminum alloy zipper with a length of 5cm

[0105] Pretreatment recipe:

[0106] Caustic soda 2.0g / L

[0107] Scouring agent Argaprep LFD 2.0g / L

[0108] 30%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com