Construction Method of Anti-sliding Pile Concrete Retaining Wall Without Bottom Form

A technology of concrete wall protection and construction method, which is applied to sheet pile wall, infrastructure engineering, construction, etc., can solve the problems of affecting the construction progress, relatively large restrictions on the progress of the wall protection, difficulty in perforating the reinforcement of the reinforcement wall, etc., so as to improve the work efficiency and reduce the perforation of the reinforcement bar. Difficulty, the effect of reducing the amount of template input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

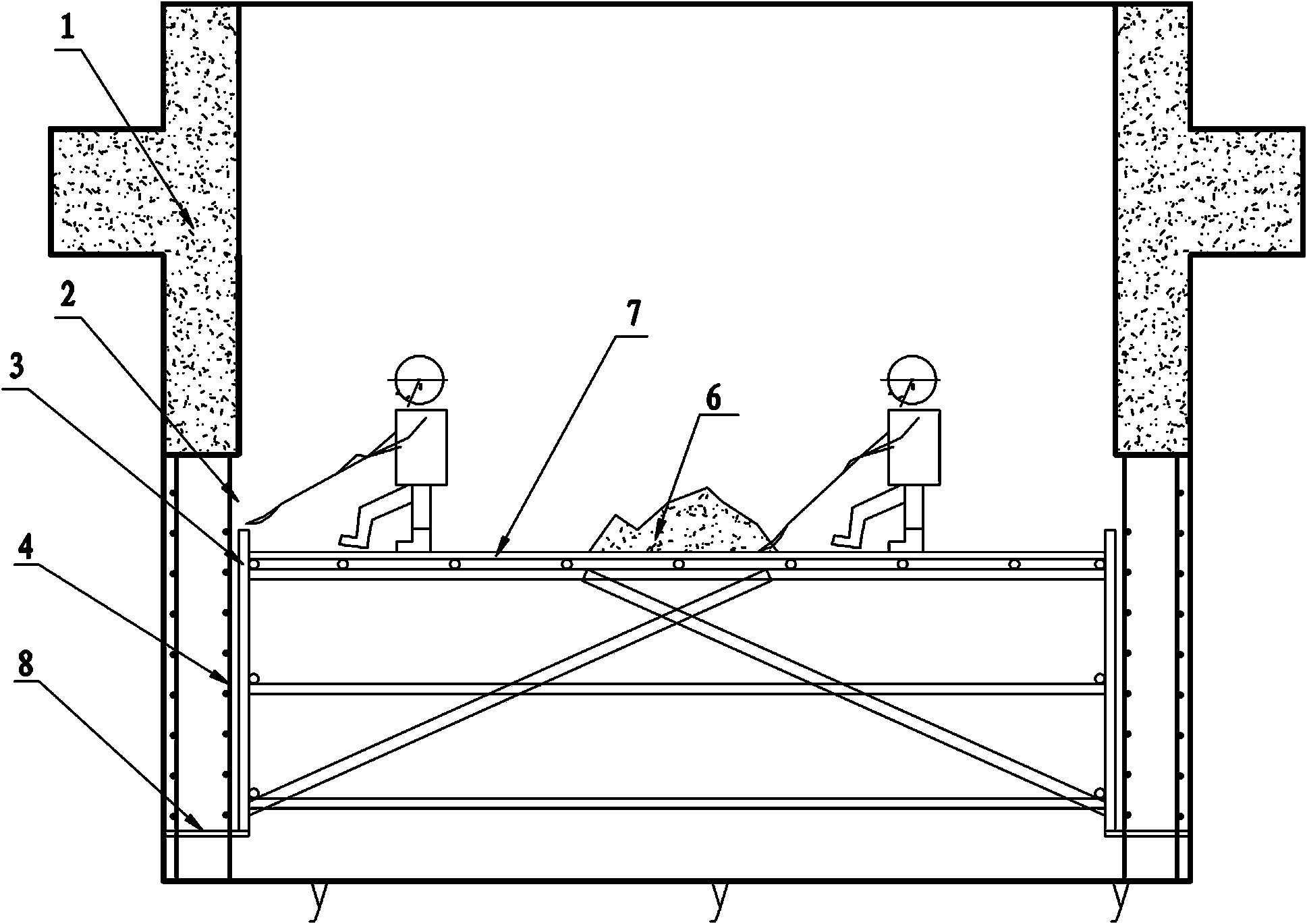

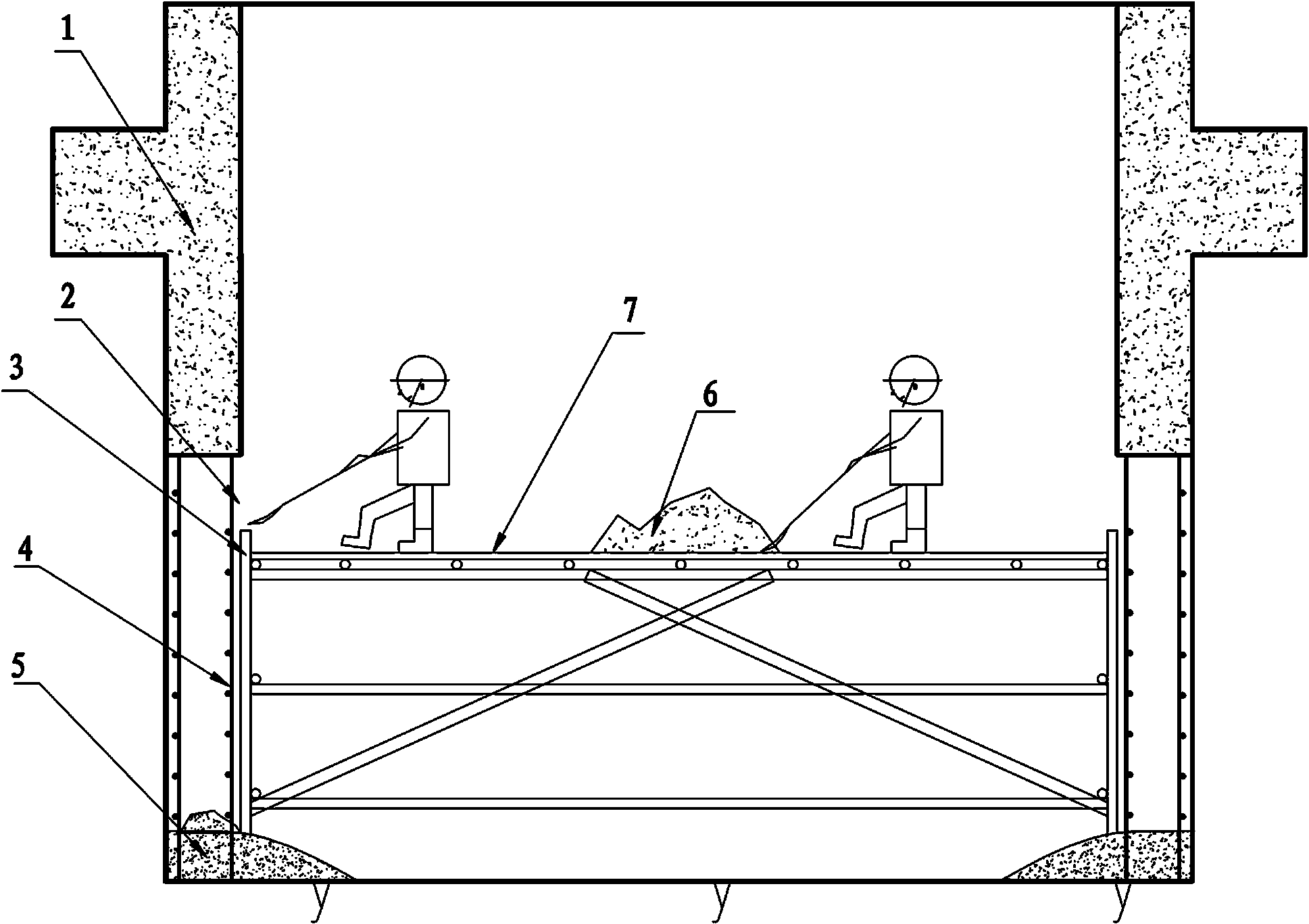

[0019] The height of each section of the anti-slide pile retaining wall is 1.5m, and the excavation depth is controlled at about 1.7m. figure 2 Among them, a bottomless formwork construction method for anti-slide pile concrete retaining wall, comprising the following steps:

[0020] 1. Welding and bundling steel bars under the poured retaining wall 1; figure 2 The reinforcing bars described in include vertical reinforcing bars 4 and transverse reinforcing bars, wherein the vertical reinforcing bars 4 protrude from the bottom of the pouring bin by a welding length. The vertical steel bars 4 protrude from the bottom 9-11d of the pouring bin, the optimal one is 10d, and the d is the diameter of the steel bar.

[0021] 2. Standing formwork, formwork 3 adopts P3015 formwork, the gaps of the formwork must be tightly connected, and rubber strips are added to the joints to stop water. A feed opening is left on the upper end of the template 3 for filling river sand and pouring conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com