Support foundation for solar photovoltaic power station and onsite construction method for support foundation

A solar photovoltaic, on-site construction technology, applied in infrastructure engineering, construction, etc., can solve the problems of difficult construction management, long construction period, poor quality, etc., and achieve the effect of reducing concrete consumption, construction cost, and construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

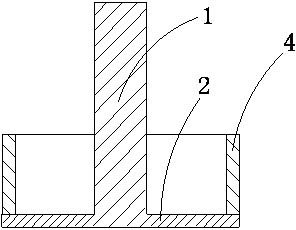

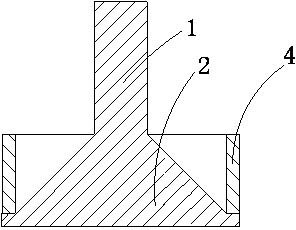

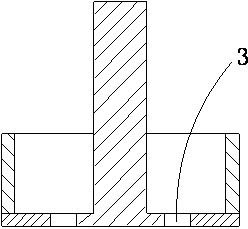

[0022] see figure 1 and figure 2 , the prefabricated part of the bracket foundation used in the solar photovoltaic power station in the present invention is composed of a central column 1, a base 2, and a cylinder section 4, the base 2 is arranged at the bottom of the central column 1, and the central column 1 is located on the base 2 At the center position of the upper part, the cylinder section 4 is arranged on the base 2, the plane size of the cylinder section 4 is not larger than the plane size of the base 2, and a cavity is formed between the cylinder section 4, the central cylinder 1 and the base 2, and the cavity The interior is filled with sand and gravel earth, and the weight of the sand and gravel earth constitutes a part of the overall weight of the support foundation. When in use, the support column of the solar photovoltaic panel is installed on the top of the central column 1 .

[0023] Because the support foundation of the present invention has the same eleva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com