Method for supporting lamellar soft rock laneway by wire rope anchors

A technology of bolt support and steel wire rope, which is used in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the problems of aggravated rock mass damage, unsatisfactory support effect, initial position and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

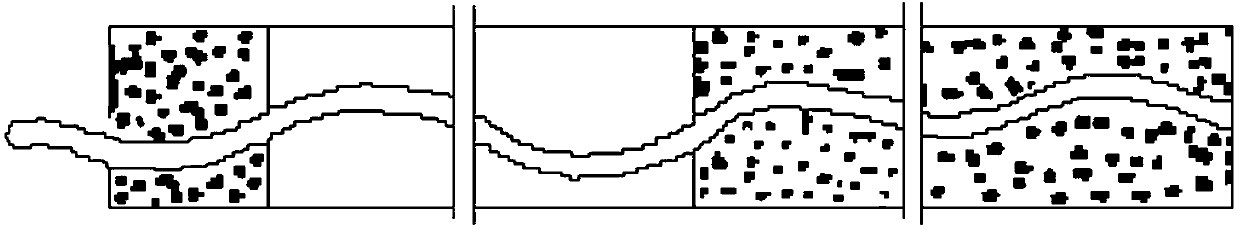

Embodiment 1

[0038] 1) Test site: The test was chosen in the main vein connecting road at the footwall of the 750th line at the level of 1621 in the west. This section is mainly composed of relatively loose quartz horn-porphyritic tuff. There is less fissure water in the rock formation and relatively developed small joints. Group: ①32°∠26°②90°∠85°③240°∠44°~60°, but the extension is not large, most of them are closed, and the lamellae are well developed. Chipping occurrence: 210°∠60°, low surface strength, can fall off by hand. The upper part of the 1645 level and 1633 level is supported by a single threaded steel bolt, which fails to effectively prevent the rock flakes and top blocks from falling. In addition to the impact of later mining, the damage to the roadway is more serious, and some bolts are exposed outside the hole. Resulting in part of the amount of ore can not be recovered. Accordingly, it has been demonstrated that steel wire rope bolts are used for support.

[0039] 2) Anch...

Embodiment 2

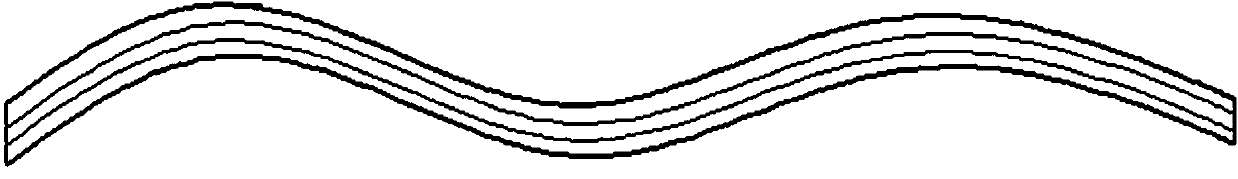

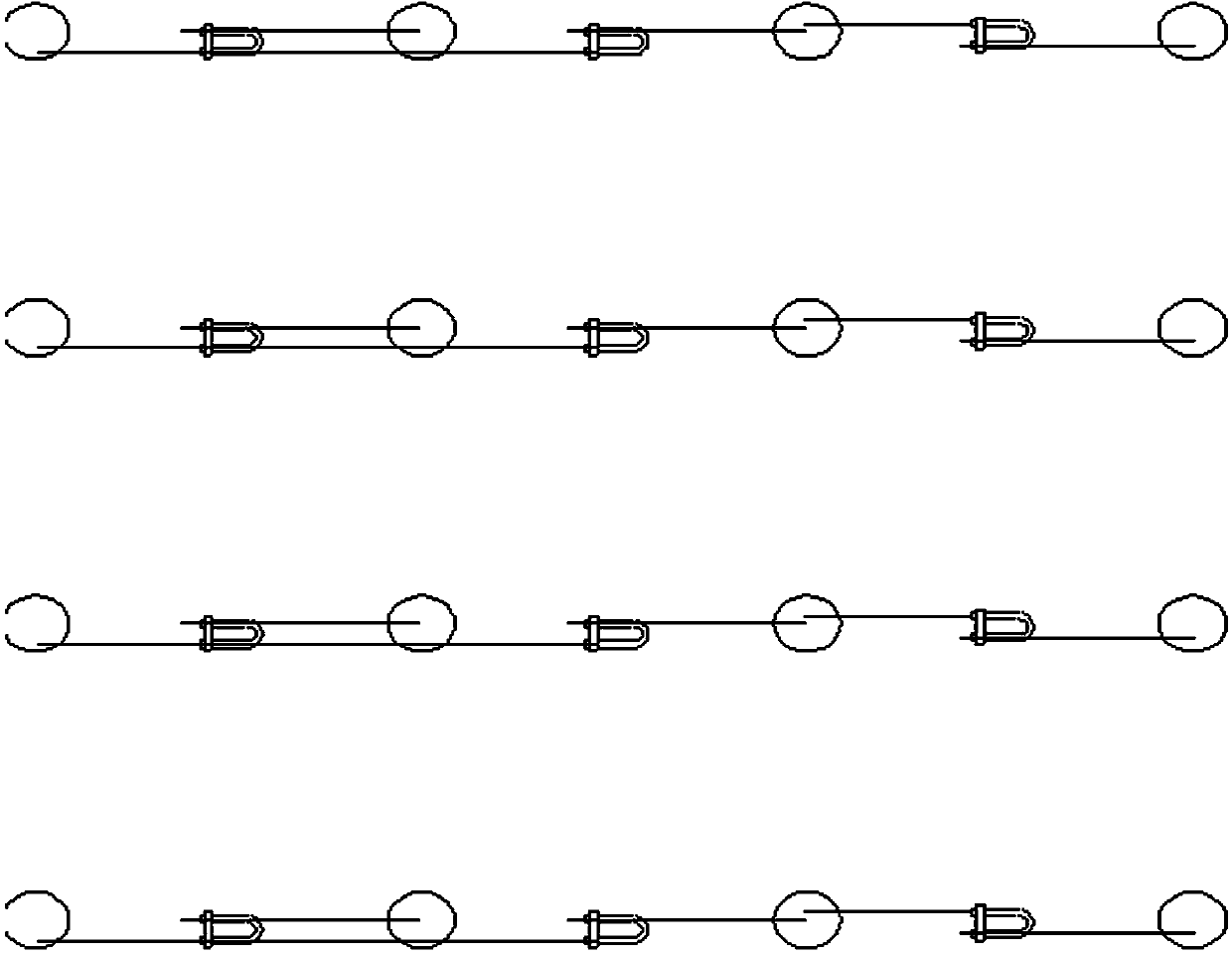

[0045] Use a rock drill to drill anchor holes with a diameter of 40mm and a depth of 1500mm on the layered rock mass. The distance between two adjacent anchor holes is 700mm; by weight percentage, take 65% of cement, 25% of white cement, and naphthalene It is 3% water reducer and 7% gypsum; stir the components evenly, put them into a packaging bag made of long-fiber water filter paper with a size of Φ30mm×230mm, and sew the packaging bag into a cylindrical shape with thread , to make a cement binder roll body; after immersing the cement binder roll body in clean water for 60s, send it into the drilled anchor hole; in order to ensure that the anchor rod and the steel wire rope net are connected as a whole, take a length of 3200mm Insert the steel wire rope anchor into the anchor hole of the cement binder roll, insert the steel wire rope anchor to the bottom of the anchor hole, the length of the steel wire anchor left outside the anchor hole is 1700mm; Fix the bolt holes of the ...

Embodiment 3

[0047] Use a rock drill to drill anchor holes with a diameter of 40mm and a depth of 1800mm on the layered rock mass. The distance between two adjacent anchor holes is 1000mm; by weight percentage, take 75% of cement, 18% of white cement, and naphthalene It is 2% water reducer and 5% gypsum; stir the components evenly, put them into a packaging bag made of long-fiber water filter paper with a size of Φ32mm×230mm, and sew the packaging bag into a cylindrical shape with thread , to make a cement binder roll; after immersing the cement binder roll in clean water for 90s, send it into the drilled anchor hole; Insert the wire rope anchor into the anchor hole of the cement binder roll, insert the wire rope anchor to the bottom of the anchor hole, the length of the wire rope anchor left outside the anchor hole is 1200mm; for inserting the wire rope anchor Fix the bolt holes of the rods so that the wire rope bolts overlap along the direction of the roadway and are hinged together with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com