Vertical axis wind turbine and turning radius adjusting mechanism of paddles of vertical axis wind turbine

A wind turbine and radius of gyration technology, which is applied in the control of wind turbines, wind turbines at right angles to the wind direction, wind turbines, etc., can solve the problem of large deviations in the rated power of wind turbines and the inability to adjust the blade rotation adaptively. Radius, power grid impact and other issues, to achieve good technical and economic value, overcome the inability to adjust the blade turning radius, and avoid the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

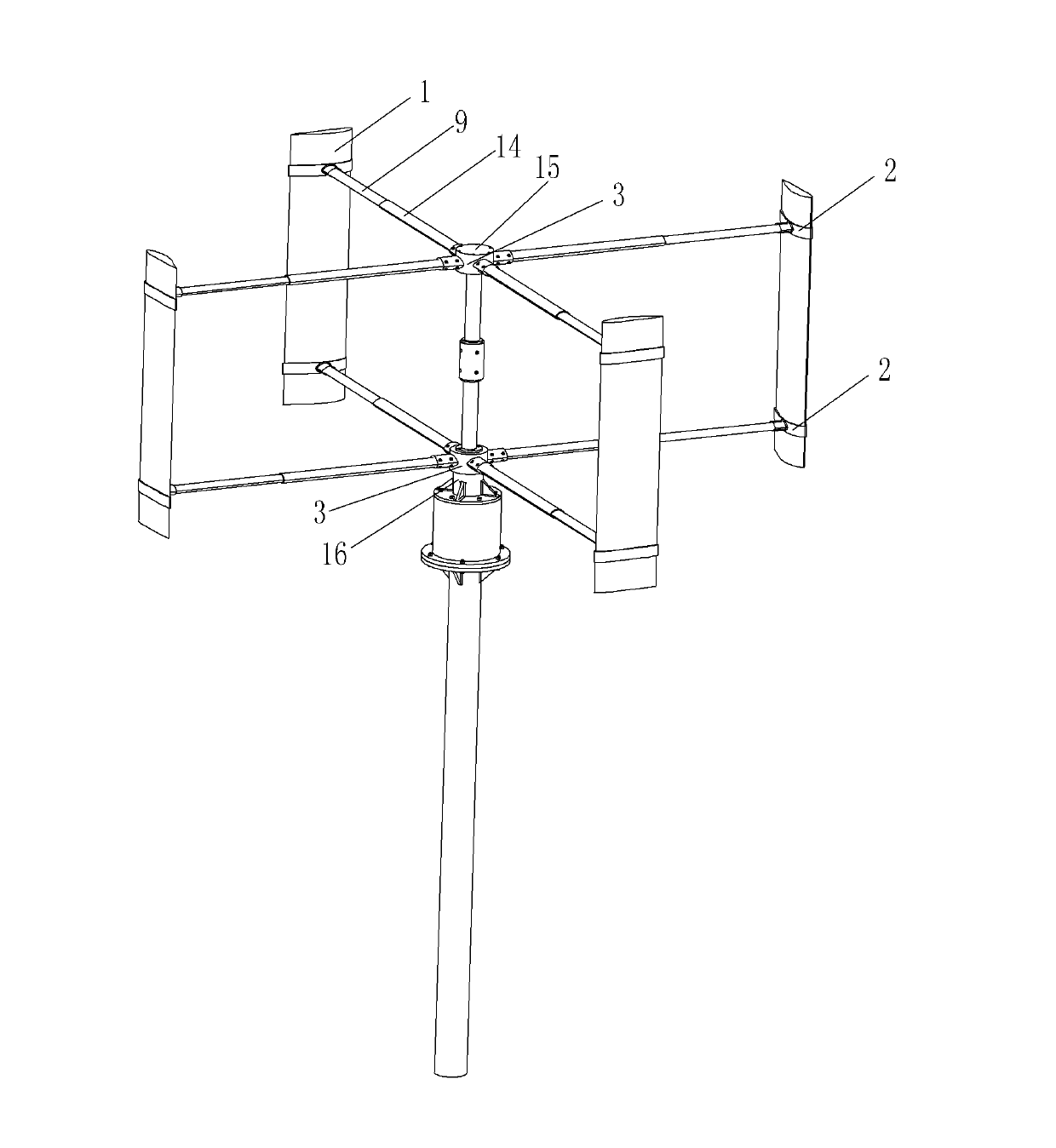

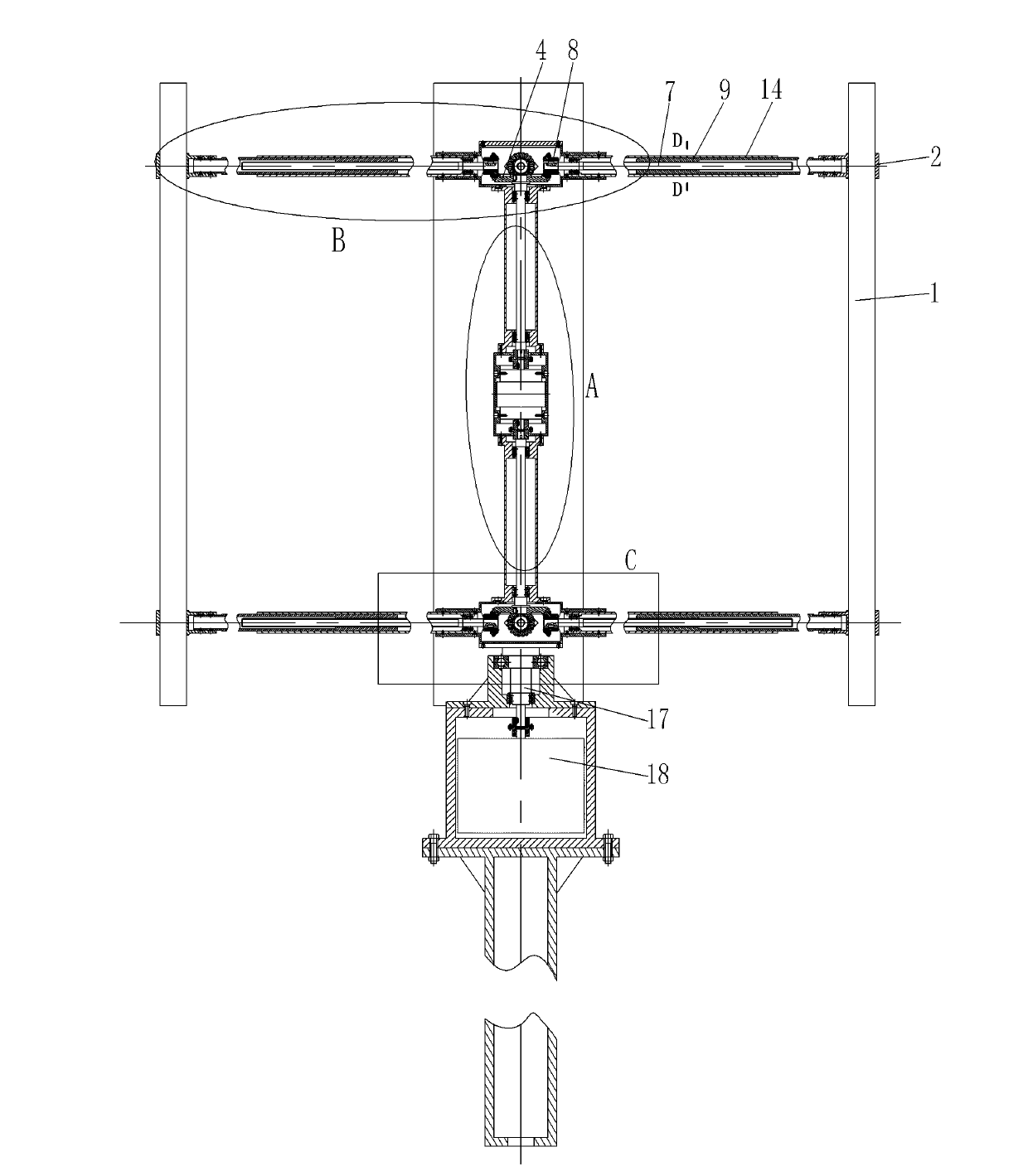

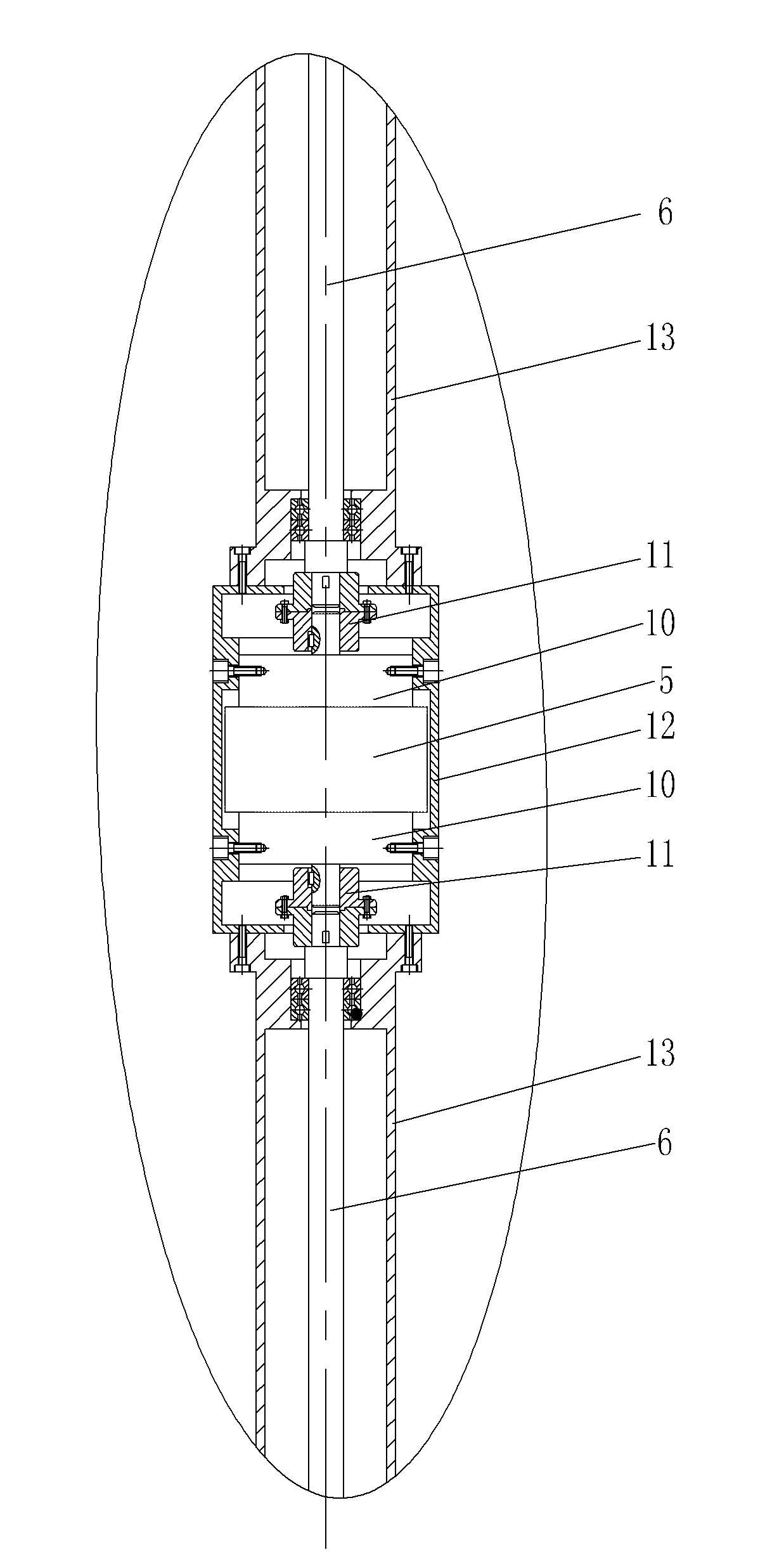

[0044] Such as Figure 1~6 As shown, the adjustment mechanism consists of a blade 1, a blade hoop 2, a fan hub shell 3, a driving bevel gear 4, a power assembly, a vertical pipe assembly and an executive assembly, wherein the blade 1 is vertically arranged, and multiple blades 1 Distributed on the same circumference, in this embodiment, the number of the blades 1 is 4, and evenly distributed on the same circumference, of course, other numbers of blades can also be used, such as 3, 5, 6...

[0045] In order to fix the paddles 1 conveniently, a blade hoop 2 is fitted on the upper and lower parts of each blade 1 respectively. The structure and arrangement of the blade hoops 2 belong to the prior art and will not be repeated here.

[0046] As an inventive point of the present invention, the power assembly, the vertical pipe assembly, the executive assembly, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com