Inducer for containment spraying pump

A shell spray pump and inducer technology, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve problems affecting the safe operation of nuclear island PWRs and effective disposal of island PWR faults , affecting the stable operation of the containment spray pump, affecting the processing quality of the inducer, etc., to achieve the effects of improving anti-cavitation performance, improving processing quality, and reducing axial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

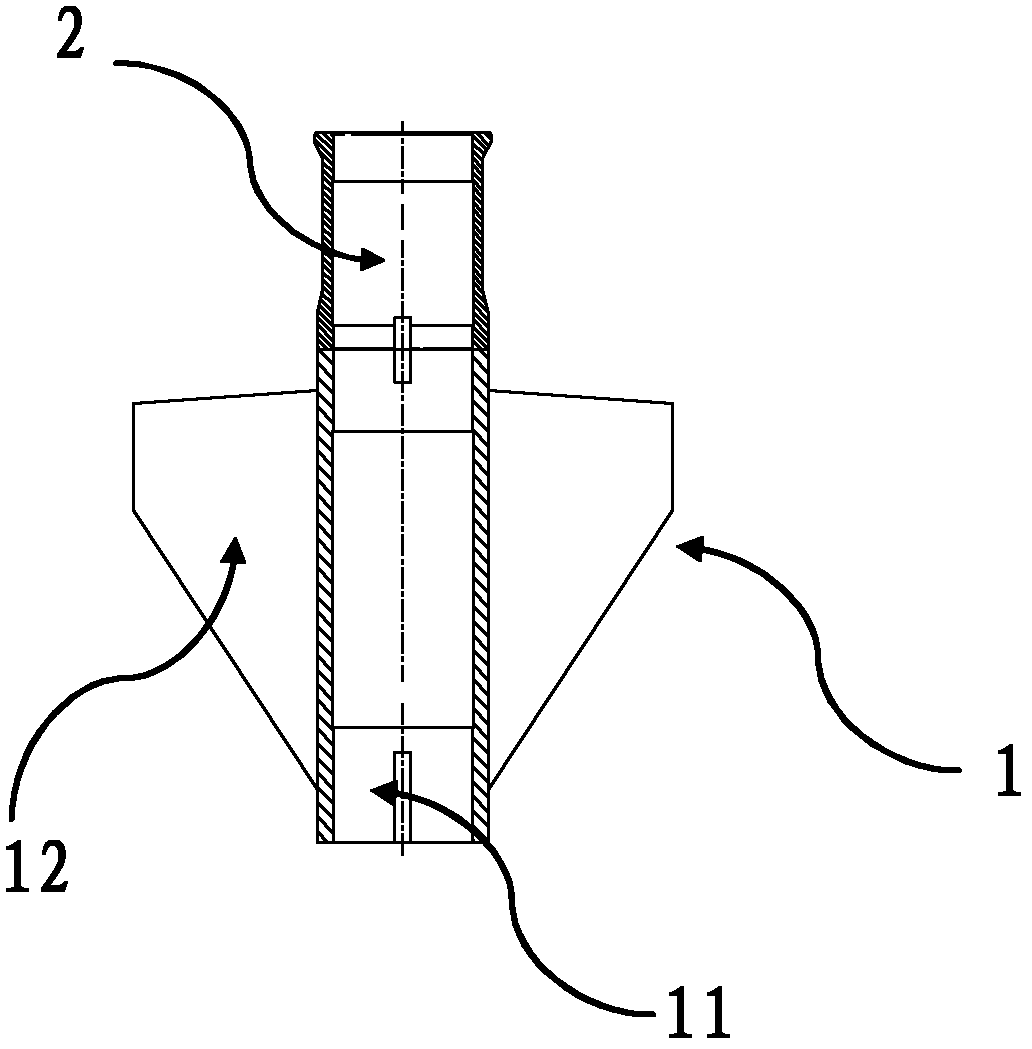

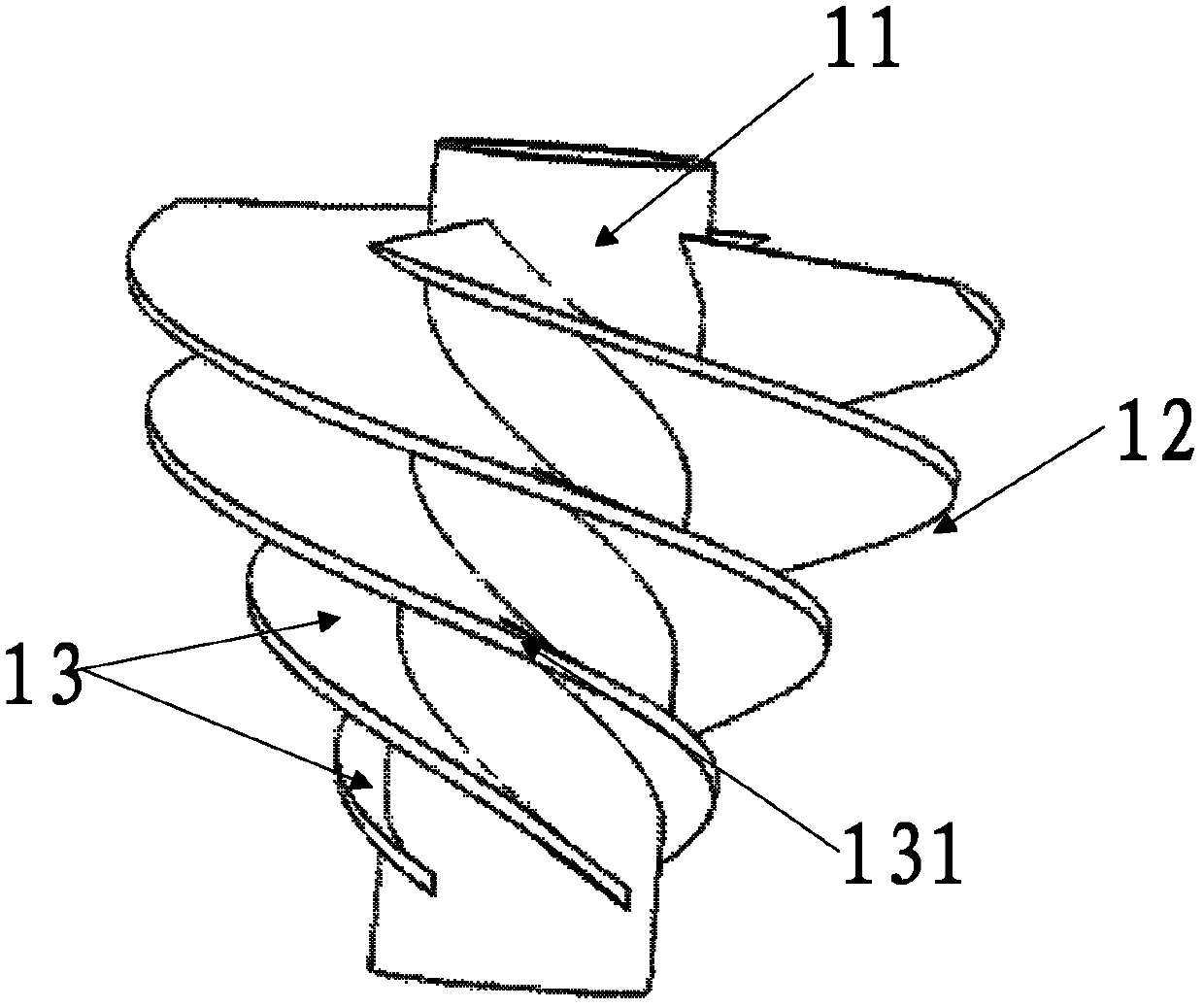

[0015] see figure 2 and image 3 , in order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments and in conjunction with the accompanying drawings:

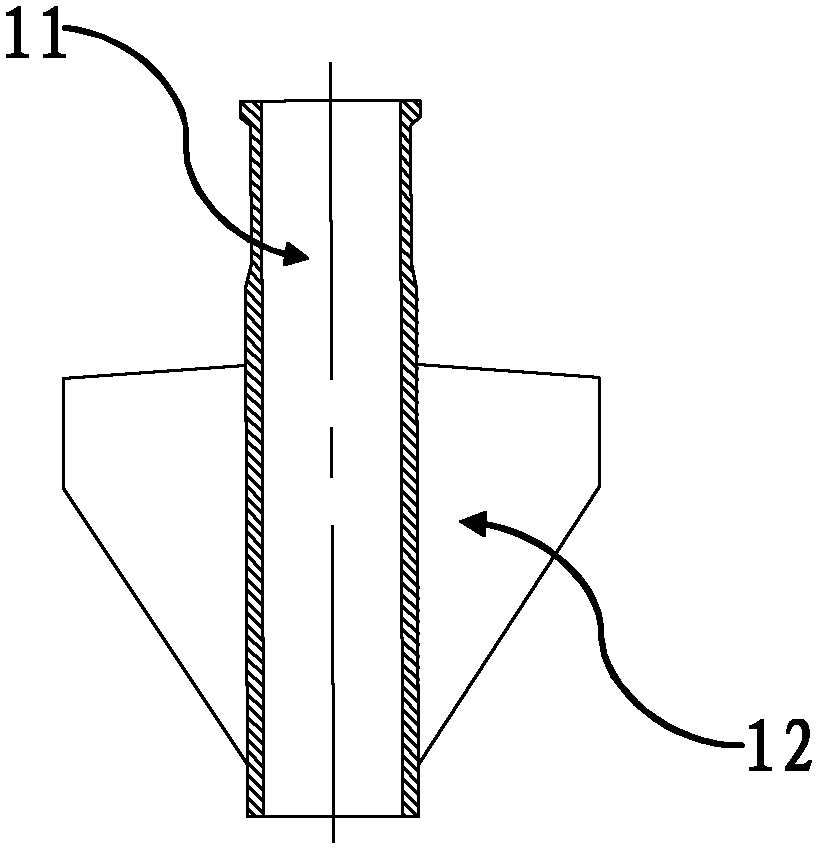

[0016] see figure 2 and image 3 , an inducer for a containment spray pump, the inducer is composed of an inducer body 1 and a shaft sleeve 2, and the inducer body 1 is composed of a hub 11 and an outer sleeve arranged on the circumference of the hub 11 Comprised of 12. During processing, the induction wheel body 1 and the shaft sleeve 2 are processed separately. After the induction wheel body 1 and the shaft sleeve 2 are processed, the bottom end of the shaft sleeve 2 is sleeved on the hub 1 top to complete the assembly of the inducer. Since the hub 11 and the hub 2 are both hollow, the inducer is installed on the pump shaft of the containment spray pump by putting the hub 2 and the hub 11 on the pump shaft. On the containment spray p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com