Air pressure loading valve positioner test bed

A technology of valve positioner and test bench, which is applied in the testing of machines/structural components, instruments, mechanical components, etc. It can solve the problems of bulky, uneven wear of loading devices, high price, etc., and achieve simple loading methods and eliminate The effect of backlash and quick connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

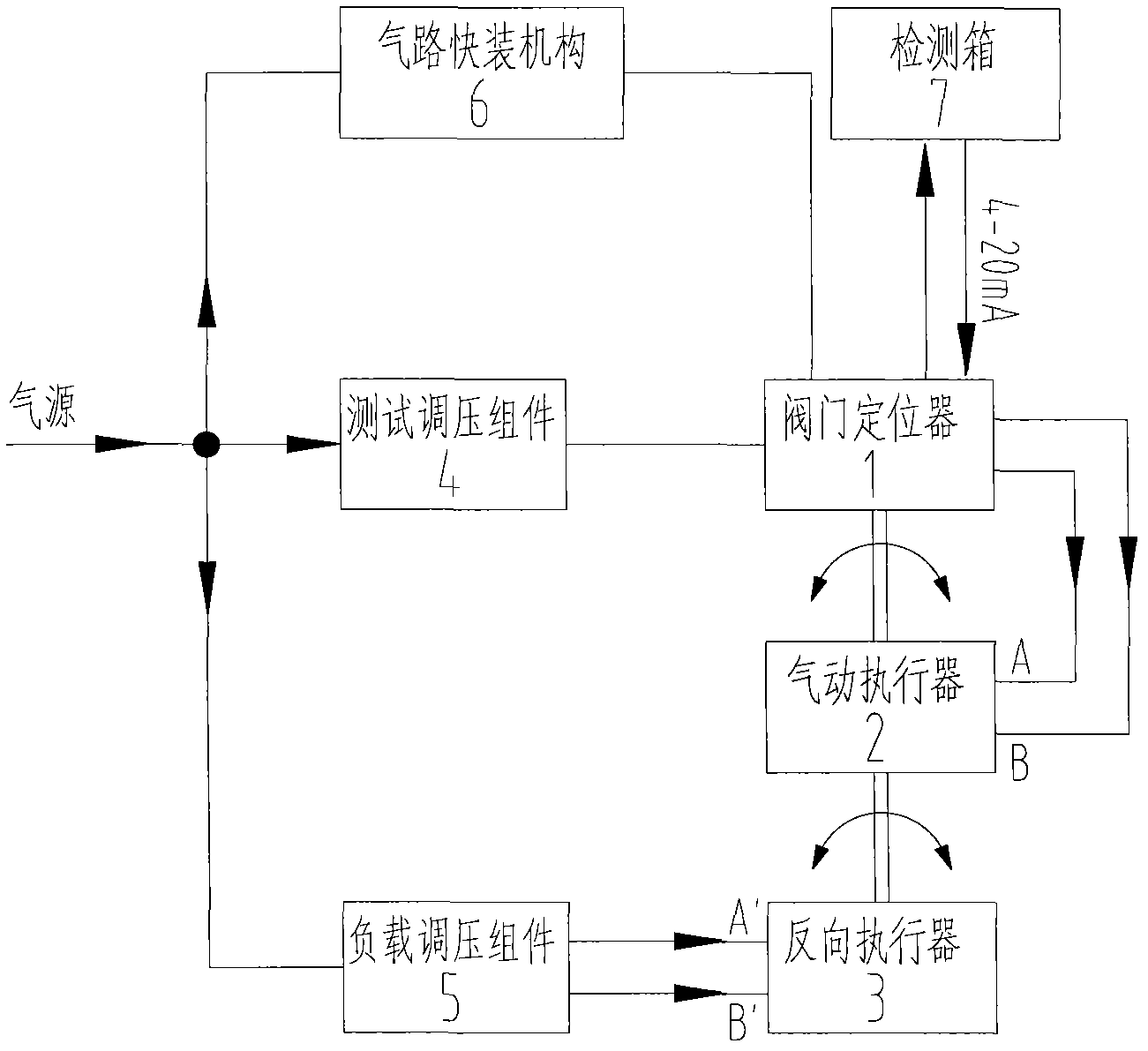

[0037] The present invention utilizes two rotary quarter-stroke double-acting pneumatic actuators as a double-acting intelligent valve positioner 1 testing load for an air pressure-loaded valve positioner test bench.

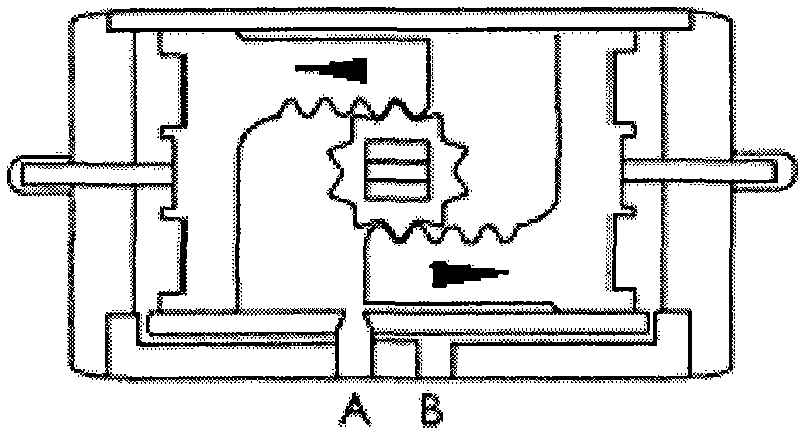

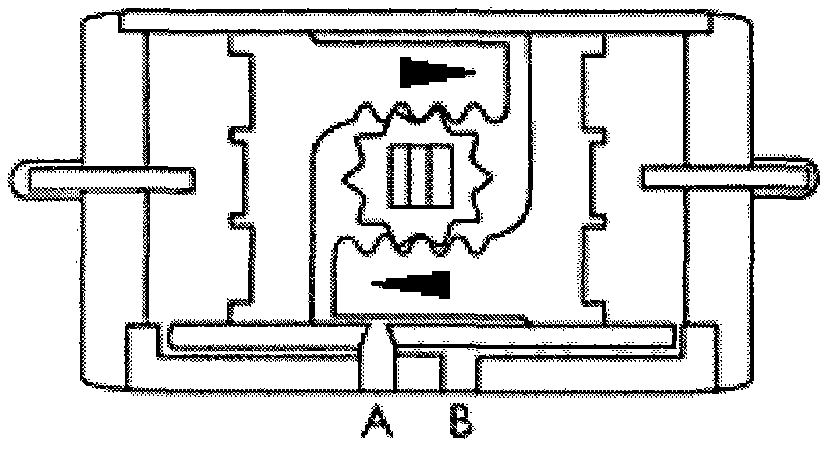

[0038] This test bench includes a control mechanism pneumatic actuator 2 that is matched with the intelligent valve positioner 1 under test, a pneumatic loading system composed of a small actuator used in reverse to simulate the load of the controlled valve, and a quick connection An air circuit quick installation mechanism for the air cavity of the pneumatic actuator 2 and the air circuit interface of the tested valve positioner 1, and a hysteresis elimination mechanism for eliminating the rotary clearance between the tested valve positioner and the pneumatic actuator.

[0039] The structure of the rotary quarter-turn double-acting pneu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com