Sample arranging system of multi-factor environmental ageing test device for composite components

A composite material component, aging test technology, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problem that the sample workpiece cannot receive light radiation uniformly, the surface area of the sample workpiece is water, and the sample workpiece cannot be uniformly exposed to rain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

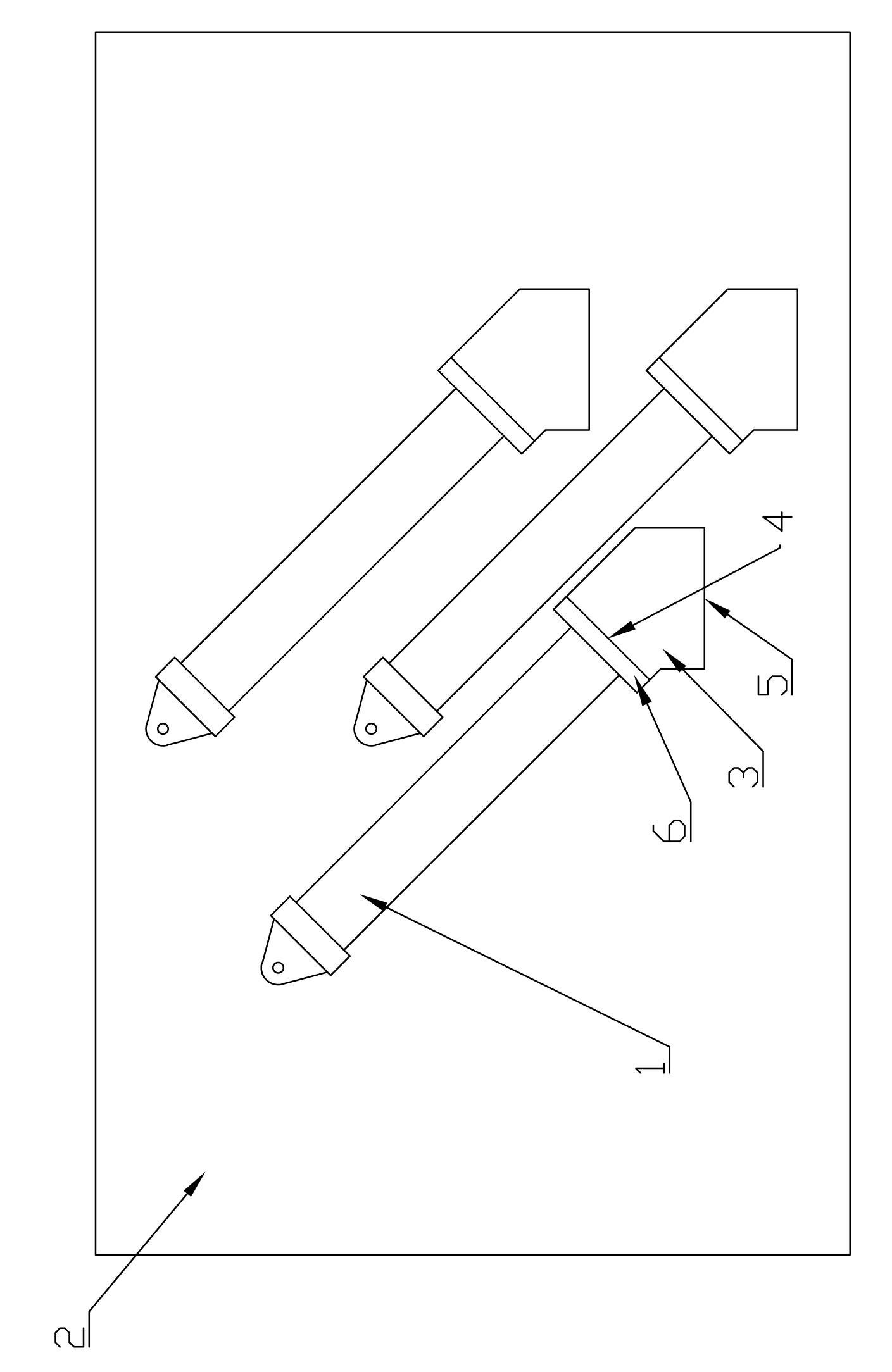

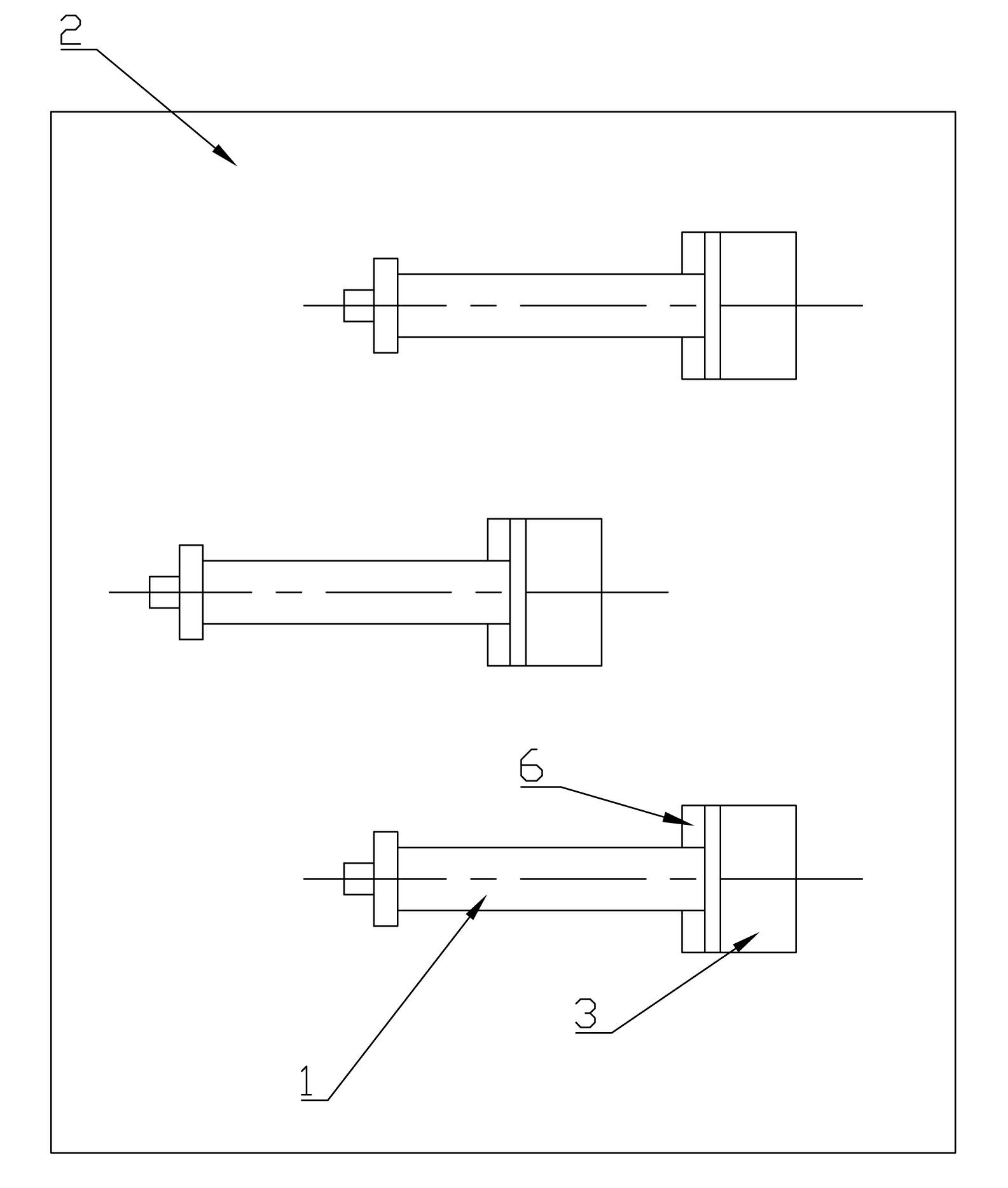

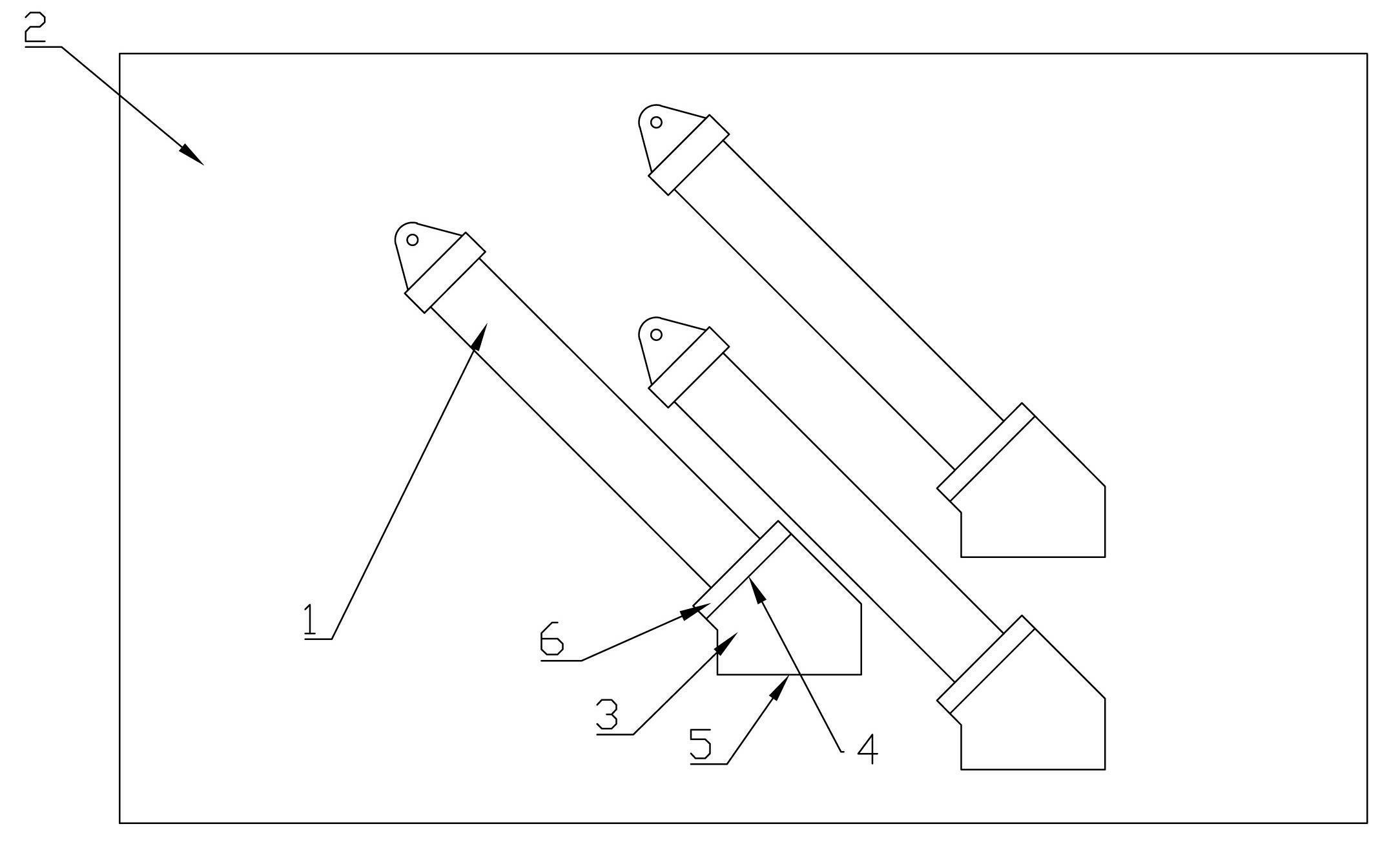

[0013] refer to figure 1 and figure 2 , a sample arrangement system of a composite material component multi-factor environmental aging test device, including a test chamber 2 and several long-rod sample workpieces 1 arranged in the test chamber 2, and the sample workpiece 1 is a finished product Glyph distribution.

[0014] By distributing the finished samples of the sample workpieces 1 in the test studio 2, the scientific distribution of the sample workpieces 1 can be made, and the installation of test accessories around the sample workpiece 1, such as the installation of the rain system and the tension system, can be made convenient. The sample workpiece 1 is placed in an ideal test environment to carry out a sample to obtain test data.

[0015] As a preferred embodiment of the present invention, it also includes a mount 3 having an upper end face 4 and a lower end face 5, the lower end of the sample workpiece 1 is connected to the upper end face 4, and there is a clamp b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com