Mixed type excitation permanent magnet, rotor for rotating electric machine using same and generator

A technology for permanent magnets and rotating motors, applied to permanent magnets, magnetic circuit rotating parts, magnetic circuits, etc., to achieve the effects of reducing magnet input, miniaturization, and reducing eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

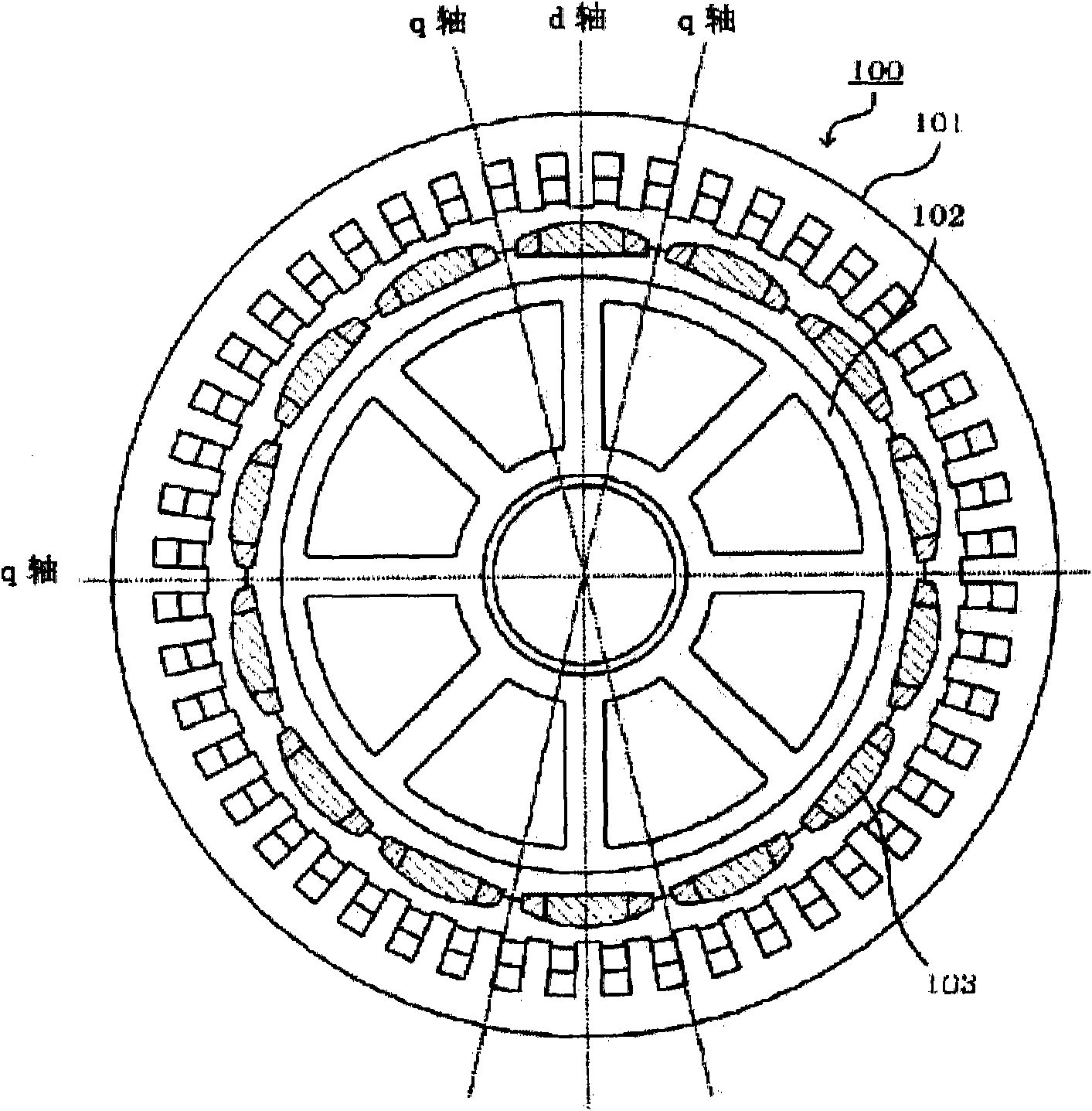

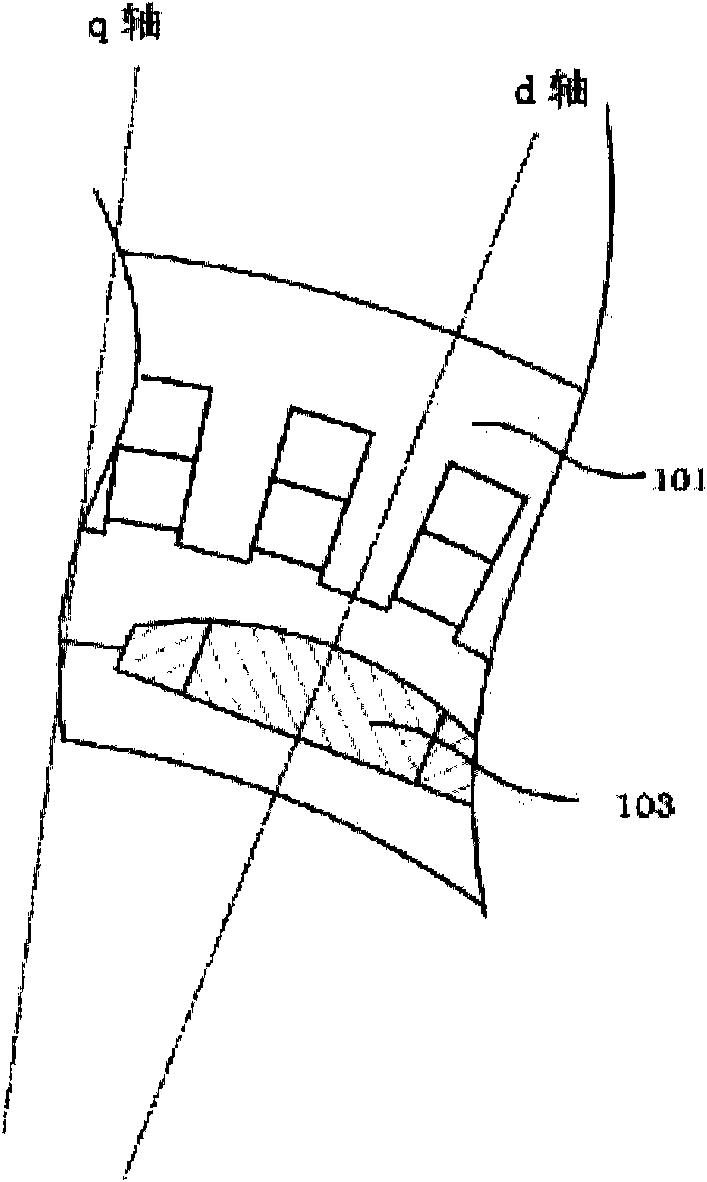

[0032] First, refer to figure 1 The configuration of the permanent magnet generator according to the first embodiment of the present invention will be described. figure 1 It is a front view of the permanent magnet generator according to the first embodiment of the present invention.

[0033] Such as figure 1 As shown, the permanent magnet generator 100 according to this embodiment has an armature part 101, an SPM rotor part 102, and a field permanent magnet 103 attached to the rotor part.

[0034] The armature unit 101 is an example of a generator armature structure, and an armature winding is wound around an armature core. When the field permanent magnet 103 rotates, an induced voltage is generated in the armature part 101 of the generator.

[0035] Formula 1

[0036] When the air gap magnetic flux density is Bg and the air gap area is Sg, then the total magnetic flux Φ is Φ=Bg·Sg. In addition, when the number of turns of the armature winding is W, the winding coefficien...

no. 2 Embodiment approach

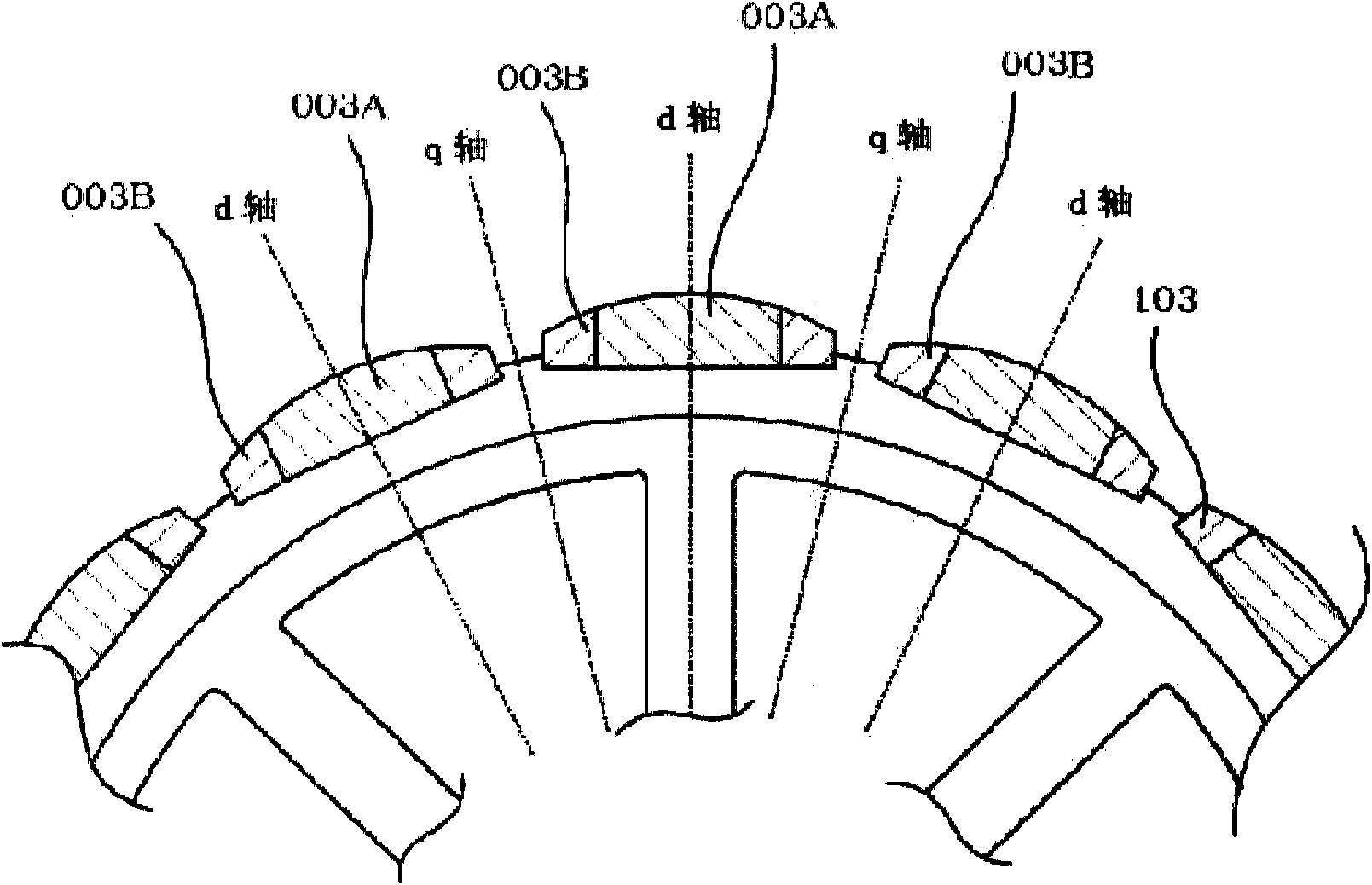

[0067] Below, refer to Figure 5 , Figure 6 , the permanent magnet generator 200 and the rotor part 202 according to the second embodiment of the present invention will be described.

[0068] The permanent magnet generator 200 according to the second embodiment is different from the permanent magnet generator 100 according to the first embodiment in that it has an IPM rotor part 202 instead of the SPM rotor part 102 , and other configurations are the same. Therefore, in the following, for the sake of convenience of description, redundant description will be appropriately omitted, and the description will focus on points different from those of the first embodiment.

[0069] The IPM rotor part 202 is different from the SPM rotor part 102 in that the permanent magnets are not provided on the surface of the rotor, but are inserted and fixed in magnet insertion holes of a cylindrical rotor made of a ferromagnetic material.

[0070] The IPM rotor part 202 has a "salient pole eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com