Small-range magnetic conductance harmonic type magnetic gear pair of radial magnetic field

A radial magnetic field and magnetic gear technology, applied in the direction of electromechanical devices, electric vehicles, electrical components, etc., can solve the problems of complex output mechanism, increase bearing radial and axial load, limit application range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

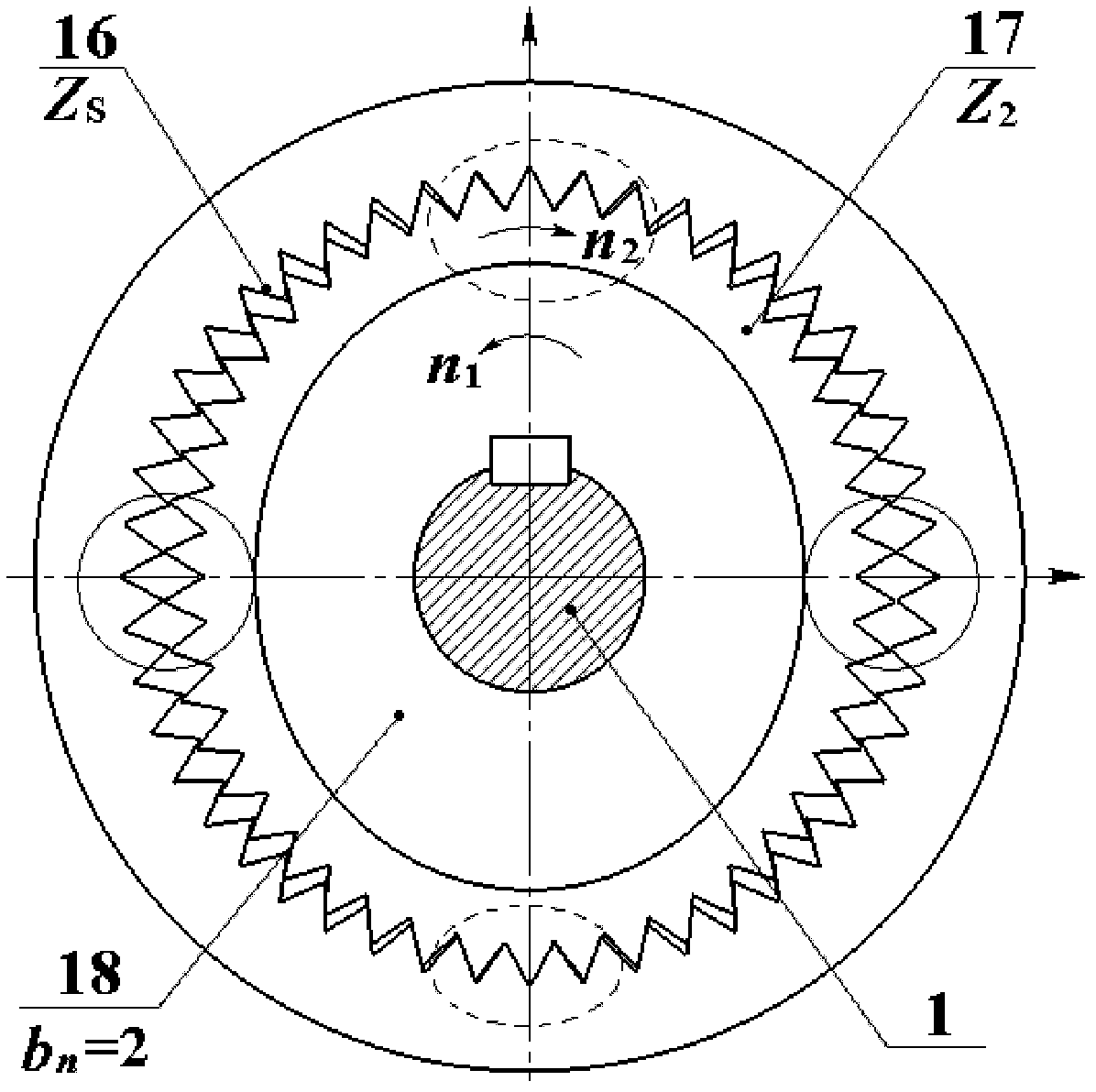

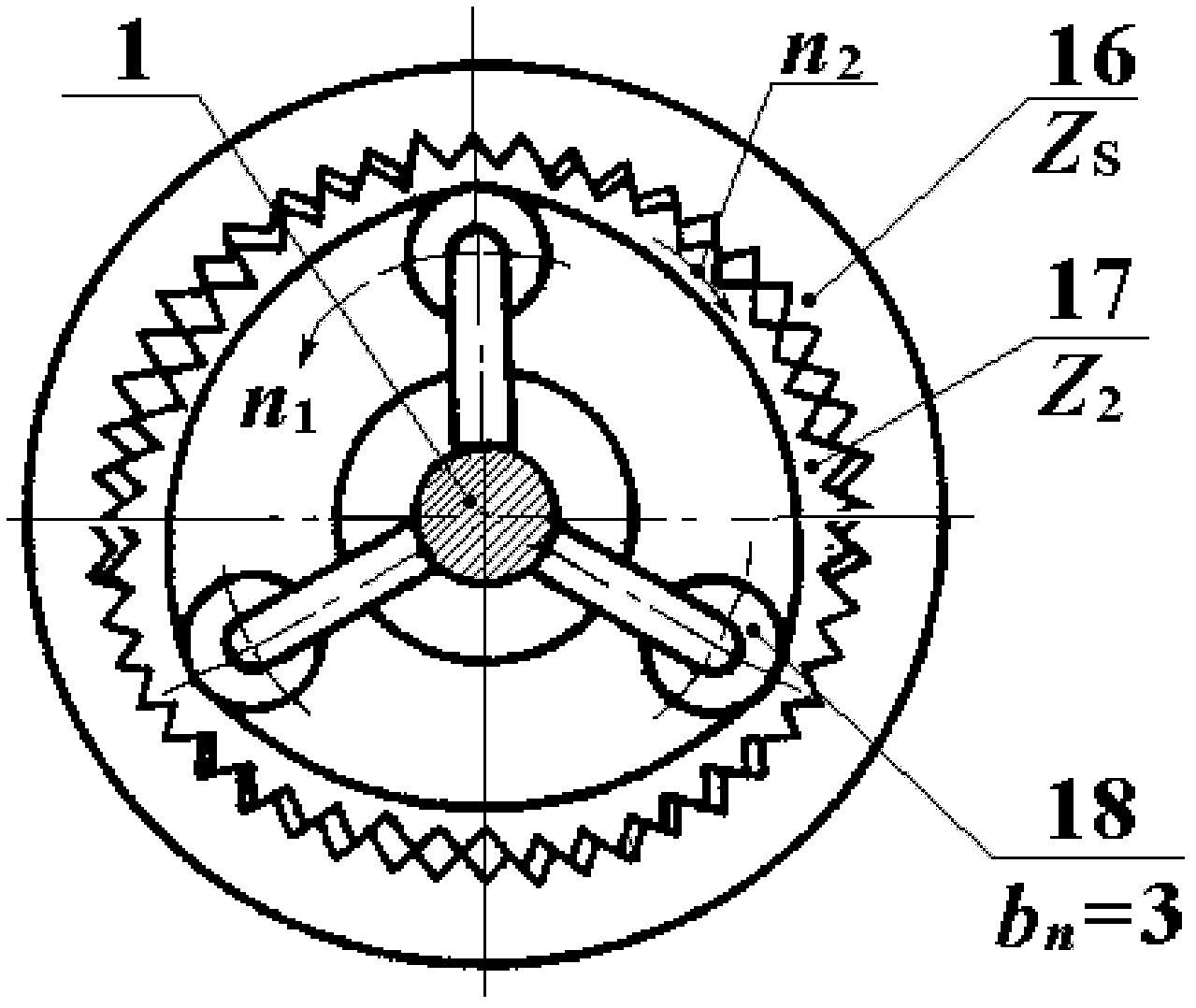

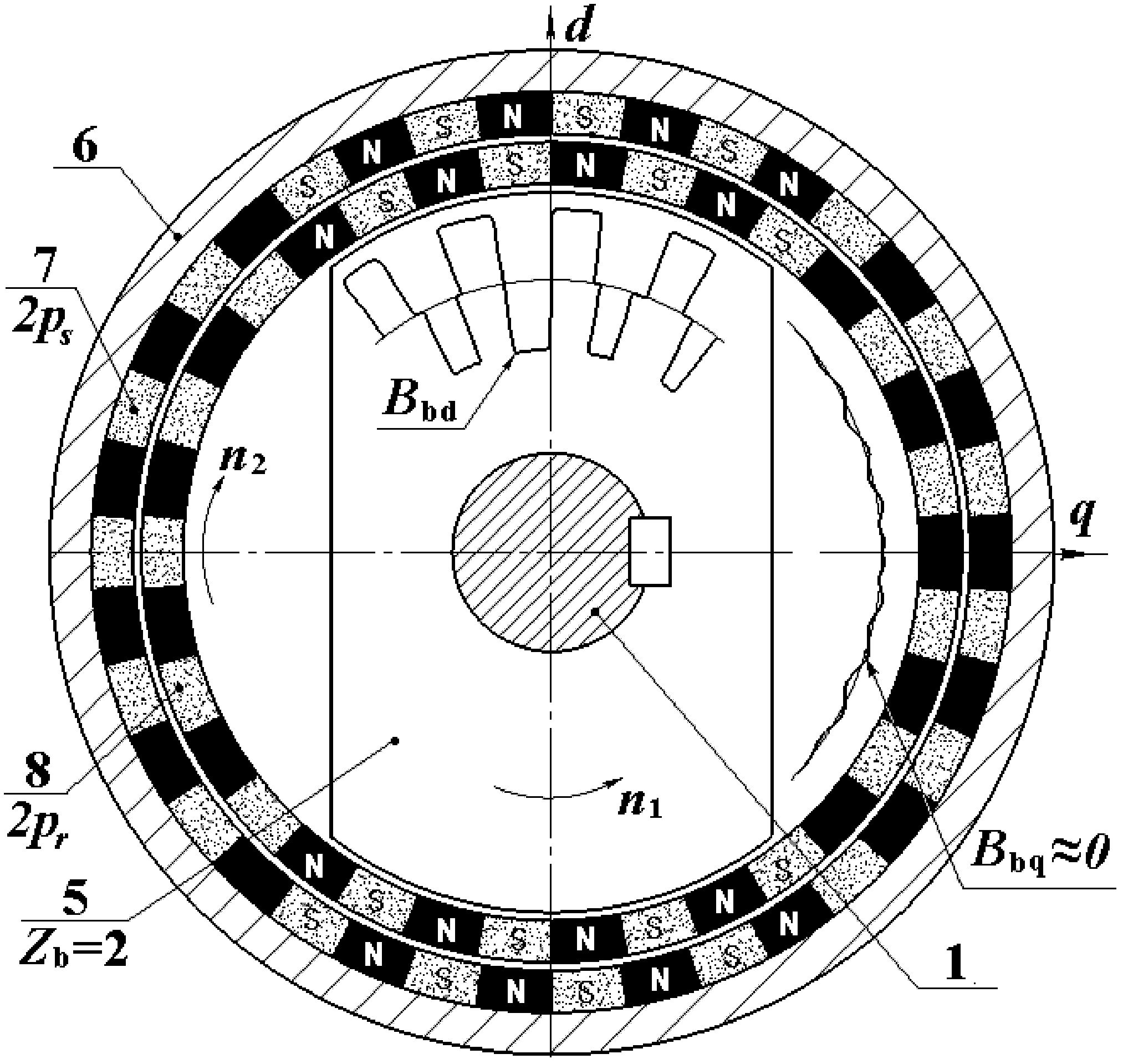

[0033] One, from image 3 , Figure 4 It can be seen that the working principle of the radial magnetic field with less pole-difference permeance harmonic wave magnetic gear pair is as follows: when working, the input shaft 1 drives the salient pole magnetic guide wave rotor 5 to rotate around the axis at high speed, driving the salient pole direct axis d direction The stator permanent magnet 7 and the rotor permanent magnet 8 are based on the principle of mutual attraction and coupling of opposite polarities, and according to the direct-axis air-gap magnetic density wave B in the direction of the d-axis bd Automatically arranged and integrated to form the attraction state of the heteropolar magnetic coupling with the largest salient pole magnetic permeability in the d-axis direction, the highest direct-axis magnetic density, and the strongest attra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com