Coal slime water concentrator

A technology of slime water and concentrator, which is applied in the direction of flocculation/sedimentation water/sewage treatment, settling tank, feeding/discharging device of settling tank, etc. It can solve the problem of easy blockage of thin-walled porous inclined square hole pipes and difficult construction , low settlement speed and other issues, to achieve the effect of easy guarantee of structural parameters, shortening the construction period and reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

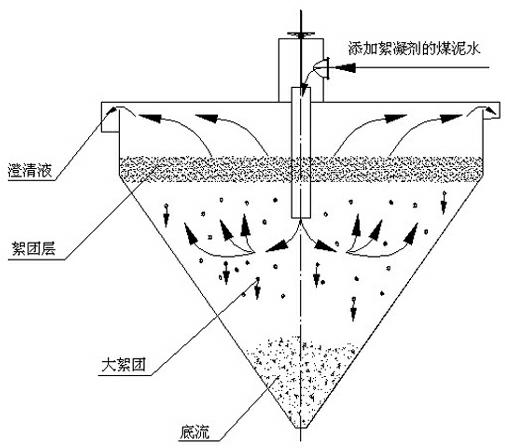

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

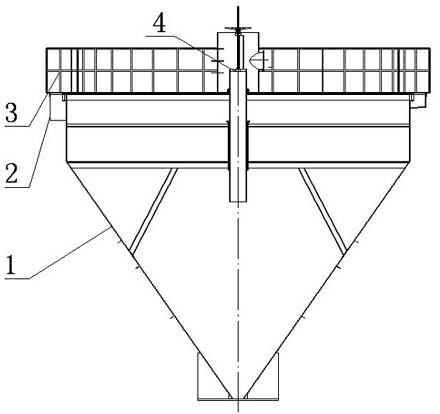

[0016] See attached Figure 1-2 , this coal slime water concentrator disclosed in the present invention, comprises the concentrator settling main body 1 that is filled with coal slime water, feeding device 4 and the clarified liquid collection tank 2 that is positioned at the outside of the top periphery of the settling main body, wherein: the concentrator settling main body 1 is a steel structure cylinder-cone with a large top and a small bottom, and the cone angle of the cone is 45-65°. The top of the settling main body 1 of the concentrator is provided with an operating platform 3 connected to the center of the settling main body.

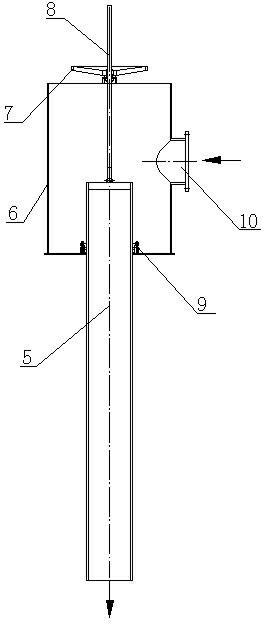

[0017] The feeding device 4 is installed at the upper center of the concentrator settling main body 1, and includes the main body 6, the feeding pipe 10 and the discharging pipe 5. The feed pipe 10 is arranged in the middle part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com