Catalyst for synthesizing 2-chloro-3,3,3-trifluoropropene from 1,1,2,3-tetrachloropropylene and preparation method thereof

A technology of tetrachloropropene and trifluoropropene, which is applied in the field of catalyst and its preparation, and can solve problems such as low selectivity, low stability, and complicated treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

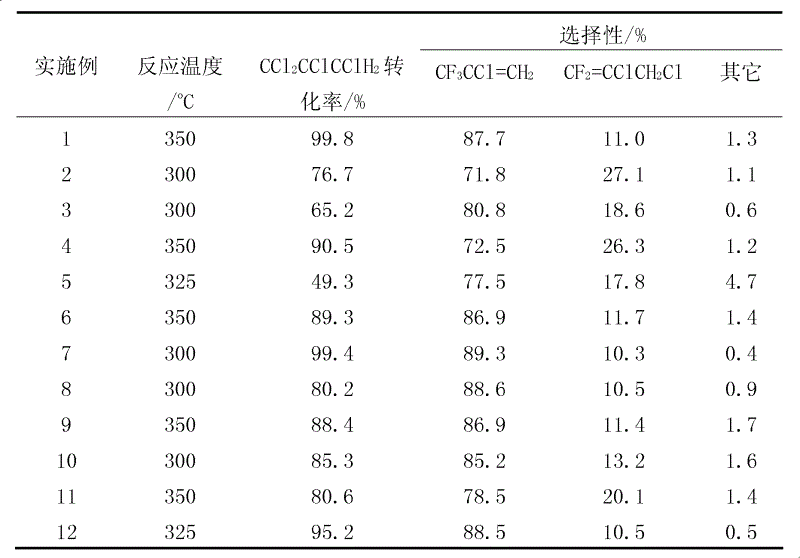

Examples

example 1

[0025] According to the Cr, Al and Zn molar ratio 1:0.1:0.05, weigh CrCl 3 ·6H 2 O, AlCl 3 and ZnCl 2 . CrCl 3 ·6H 2 O, AlCl 3 and ZnCl 2 After mixing, dissolve in water, add KOH alkali solution dropwise under stirring conditions until the precipitation is complete, and then filter to obtain Cr(OH) 3 , Al(OH) 3 and Zn(OH) 2 mixture. Add the sucrose-citric acid solution with a molar ratio of 1:1 to the mixed precipitate, mix well, and dry it under N 2Calcined at 450°C for 4 hours under the atmosphere to obtain oxides containing carbon templates. The oxide containing the carbon template was HF-N with a molar ratio of 1:4 2 The mixed gas was treated at 300°C for 12 hours, and then oxidized under an oxygen atmosphere for 10 hours to remove the carbon template to obtain CrF 3 , AlF 3 and MF 2 Composition of the catalyst of the present invention.

[0026] The catalyst prepared in Example 1 is applied to gas-phase fluorination of 1,1,2,3-tetrachloropropene to synthesi...

example 2

[0028] Weigh Cr(NO 3 ) 3 9H 2 O, Al(NO 3 ) 3 and Zn(NO 3 ) 2 ·6H 2 O. Cr(NO 3 ) 3 9H 2 O, Al(NO 3 ) 3 and Zn(NO 3 ) 2 ·6H 2 After O is mixed, it is dissolved in water, and KOH alkali solution is added dropwise under stirring conditions until the precipitation is complete, and then filtered to obtain Cr(OH) 3 , Al(OH) 3 and Zn(OH) 2 mixture. Add sucrose-citric acid solution with a molar ratio of 1:1 to the mixture, mix well, and dry it under N 2 Calcined at 450°C for 4 hours under the atmosphere to obtain oxides containing carbon templates. The oxide containing the carbon template was HF-N with a molar ratio of 1:4 2 The mixed gas was treated at 300°C for 10 hours, and then oxidized under an oxygen atmosphere for 10 hours to remove the carbon template to obtain CrF 3 , AlF 3 and MF 2 Composition of the catalyst of the present invention.

[0029] The catalyst prepared in Example 2 is applied to the fluorination of 1,1,2,3-tetrachloropropene to synthesize ...

example 3

[0031] Weigh Cr(NO 3 ) 3 9H 2 O, Al 2 (SO 4 ) 3 and Zn(NO 3 ) 2 ·6H 2 O. Cr(NO 3 ) 3 9H 2 O, Al 2 (SO 4 ) 3 and Zn(NO 3 ) 2 ·6H 2 After O is mixed, it is dissolved in water, and KOH alkali solution is added dropwise under stirring conditions until the precipitation is complete, and then filtered to obtain Cr(OH) 3 , Al(OH) 3 and Zn(OH) 2 mixture. Add sucrose-citric acid solution with a molar ratio of 1:1 to the mixture, mix well, and dry it under N 2 Calcined at 450°C for 4 hours under the atmosphere to obtain oxides containing carbon templates. The oxide containing the carbon template was HF-N with a molar ratio of 1:4 2 The mixed gas was treated at 300°C for 12 hours, and then oxidized under an oxygen atmosphere for 14 hours to remove the carbon template to obtain CrF 3 , AlF 3 and MF 2 Composition catalyst of the present invention.

[0032] The catalyst prepared in Example 3 is applied to the fluorination of 1,1,2,3-tetrachloropropene to synthesize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com