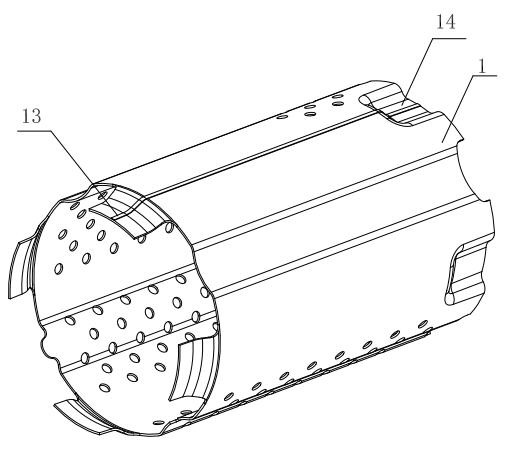

Process and die for one-time round-bending and molding

A technology for forming molds and concave molds, applied in the field of stamping, can solve problems such as complex processes, and achieve the effects of good forming effect, low cost, and halving of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

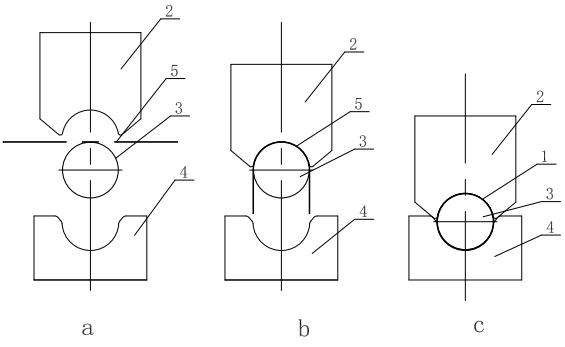

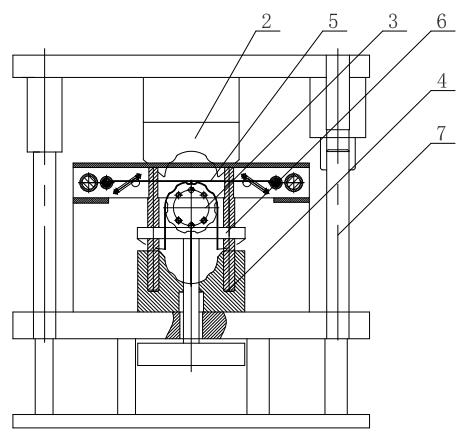

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0016] Such as figure 2 As shown, the one-time bending and rounding forming process described in the present invention is formed by one-time pressing of a single set of molds, and the sheet material 5 that has been punched and blanked is placed horizontally between the upper die 2 and the mandrel 3 (see figure 2 a) The upper die 2 moves downward to bend and press the two edges of the sheet material 5 into a vertical state. When the upper die 2 is in place, the cavity between the upper die 2 and the mandrel 3 forms the upper semicircle of the workpiece 1. (See figure 2 b); then the upper die 2 and the mandrel 3 go down at the same time, and the two edges of the sheet 5 touch the arc surface of the lower die 4, are gradually closed and finally formed in the cavity between the lower die 4 and the mandrel 3 Out of the lower semicircle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com