System and method for producing colored sand plate

A production system and production method technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of low degree of automation, high labor intensity, large sand laying error, etc., and achieve uniform sand laying and automation. High degree of labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

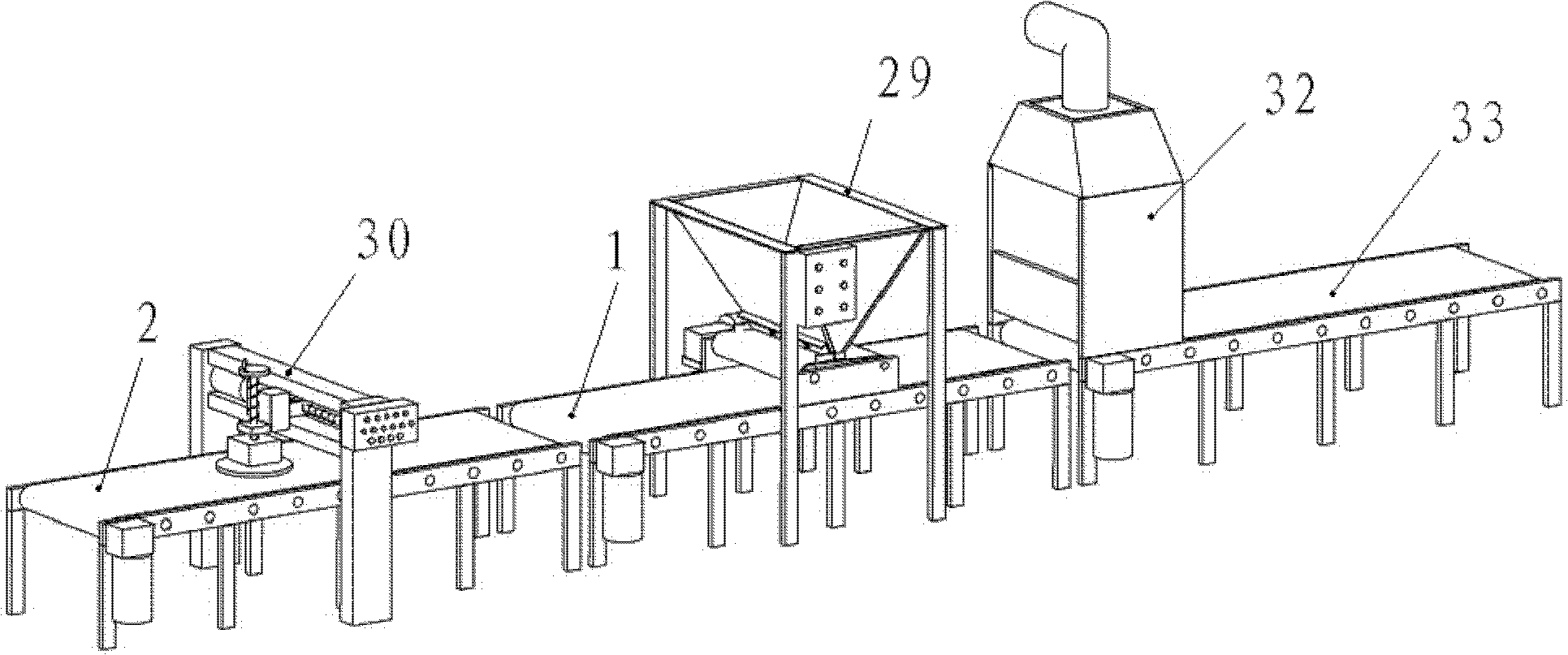

[0040] Such as figure 1 As shown, the colored sand board production system of this embodiment includes a glue spraying subsystem, a cloth sand subsystem, and a pressing and polishing system arranged in sequence; The first substrate plate conveying device 33; the cloth sand subsystem includes a sand leaking device 29 and the second substrate plate conveying device 1 arranged below the sand leaking device 29; the pressing polishing system includes a pressing polishing device 30 and is arranged on Press the third substrate plate transfer device 2 below the polishing device 30 .

Embodiment 2

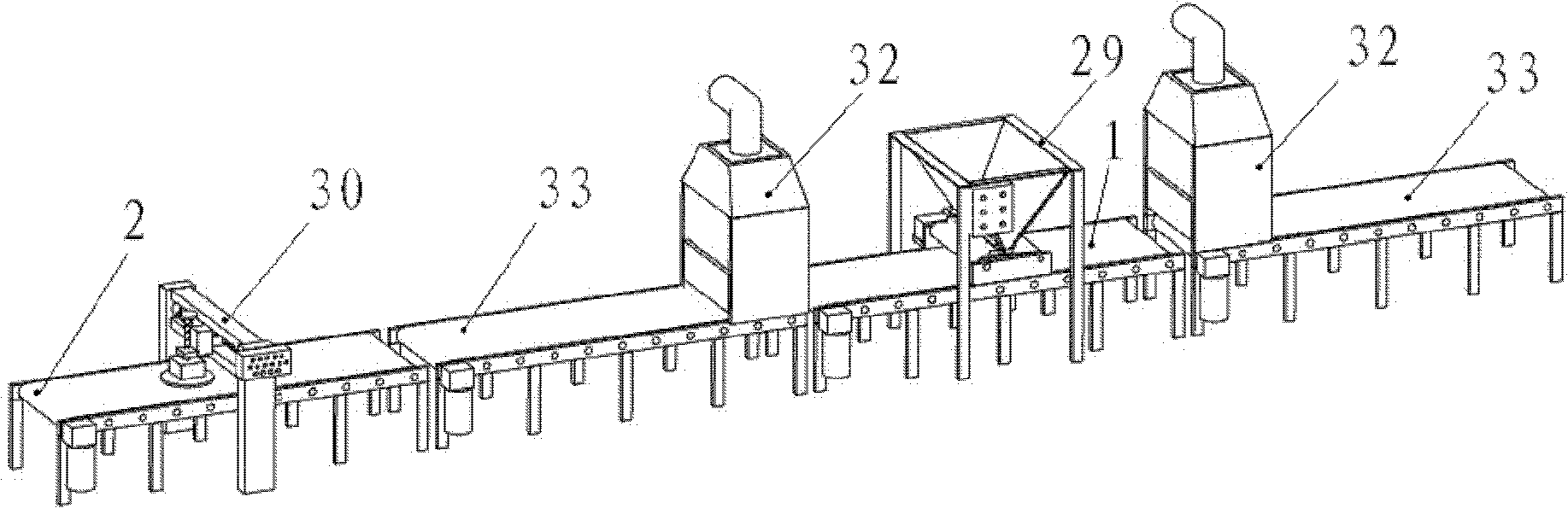

[0042] Such as figure 2 As shown, the colored sand board production system of this embodiment includes a glue spraying subsystem, a sand distribution subsystem, a glue spraying subsystem, and a pressing and polishing system arranged in sequence.

[0043]Described glue spraying subsystem comprises glue spraying device 32 and is arranged on the first base plate transfer device 33 below glue spraying device 32; Substrate plate transfer device 1 ; the press polishing system includes a press polish device 30 and a third substrate plate transfer device 2 disposed below the press polish device 30 .

Embodiment 3

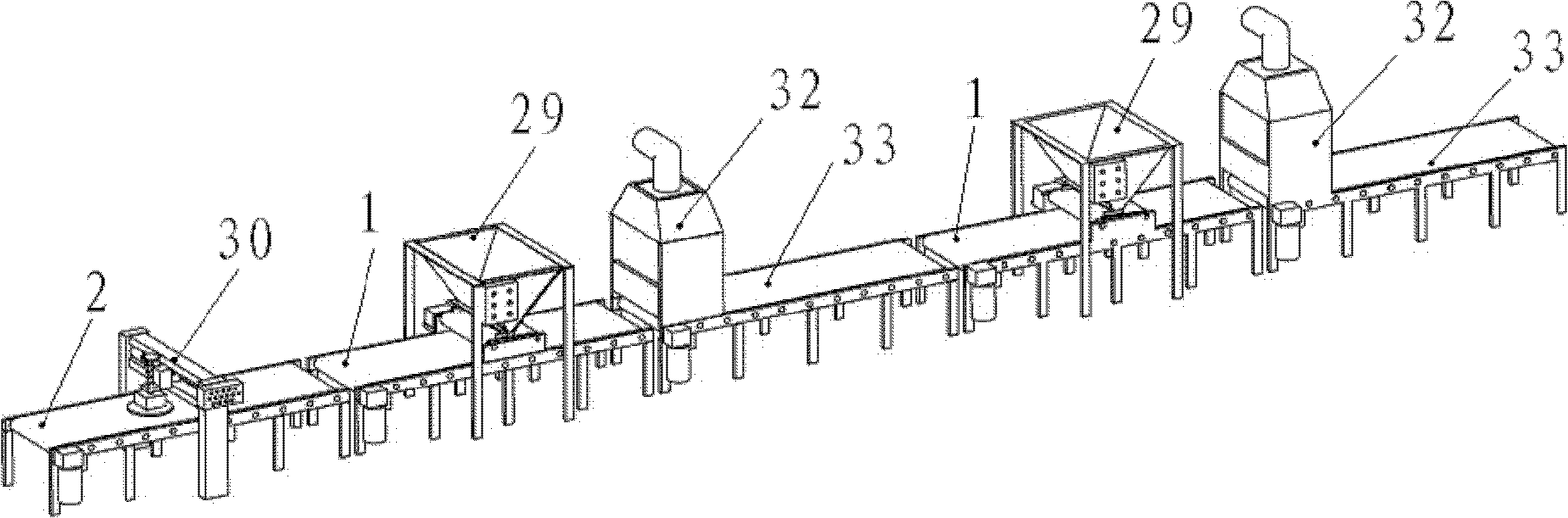

[0045] Such as image 3 As shown, the colored sand board production system of this embodiment includes a glue spraying subsystem, a sand distribution subsystem, a glue spraying subsystem, a sand distribution subsystem, and a pressing and polishing system arranged in sequence.

[0046] Described glue spraying subsystem comprises glue spraying device 32 and is arranged on the first base plate transfer device 33 below glue spraying device 32; Substrate plate transfer device 1 ; the press polishing system includes a press polish device 30 and a third substrate plate transfer device 2 disposed below the press polish device 30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com