Nano material computer to plate (CTP) printing device

A printing device and nano-material technology, applied in printing, printing plate preparation, etc., to achieve the effect of accuracy, stable operation, and small occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

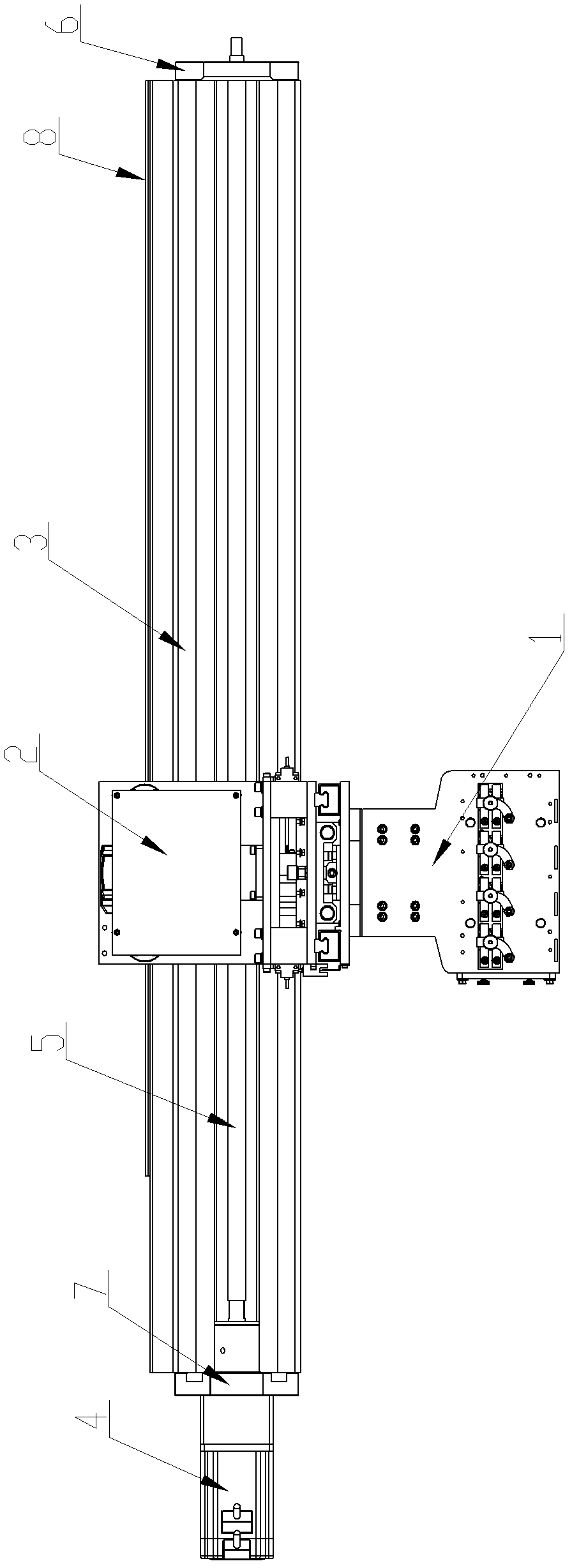

[0035] Embodiment 1: as figure 1 , figure 2 As shown, the present invention includes a bottom plate 238, a V-shaped guide rail 3, a lifting device 2, a horizontal transmission mechanism and a nozzle combination device 1, and the nozzle combination device 1 and the sliding plate 222 of the lifting device 2, a horizontal transmission mechanism and a V-shaped guide rail 3 The V-shaped sliding seat bodies are respectively connected and slide along the V-shaped guide rail 3.

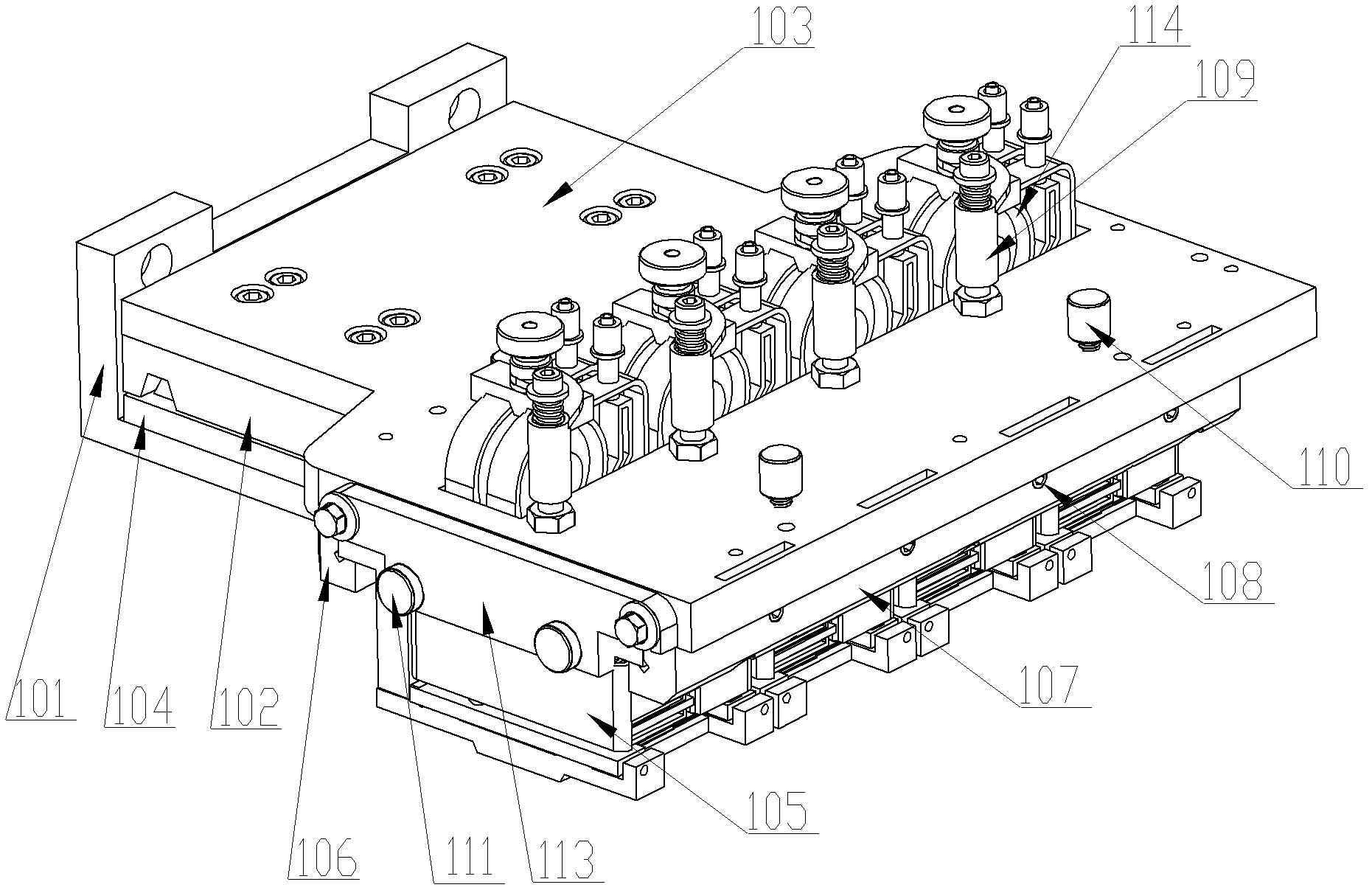

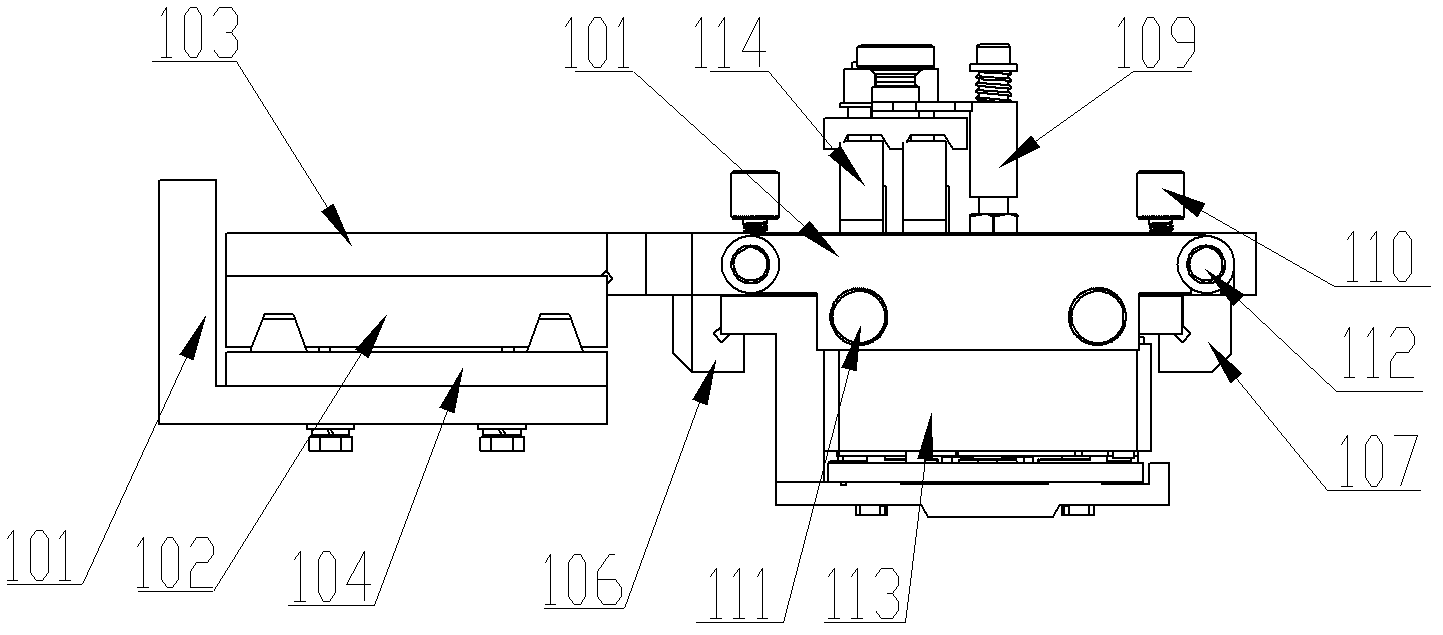

[0036] Such as Figure 7 , Figure 8 As shown, the lifting device 2 includes a drive mechanism, a transmission adjustment mechanism, a middle plate 211, a sliding plate 222 and a positioning mechanism. The gear 234 meshes, and the other end is installed on the sliding plate 222 through the roller seat body 210, and the middle plate 211 is installed on the main board 203 of the transmission adjustment mechanism. One end of the positioning mechanism is connected with the middle plate 211, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com