Fiber web winding machine and method

A fiber web and winding machine technology, applied in the field of intermediate winders, fiber web post-processing devices, and fiber web winding devices, can solve problems such as inconsistent working postures and achieve high-speed operation stability , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]If not stated otherwise, in the figures, the same reference numerals are used for parts and components that correspond to each other.

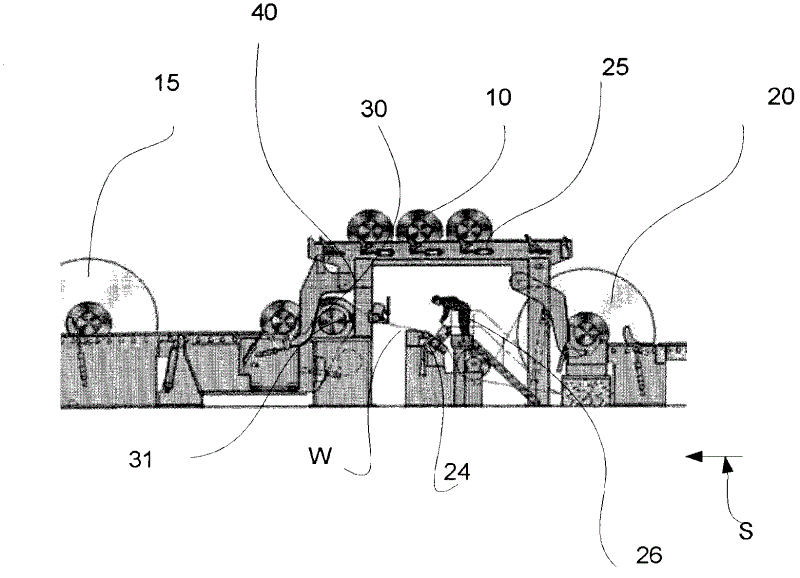

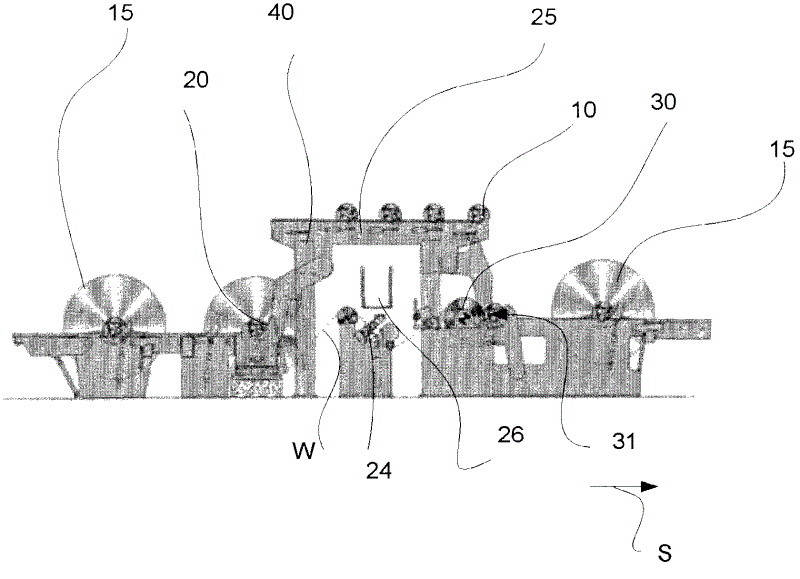

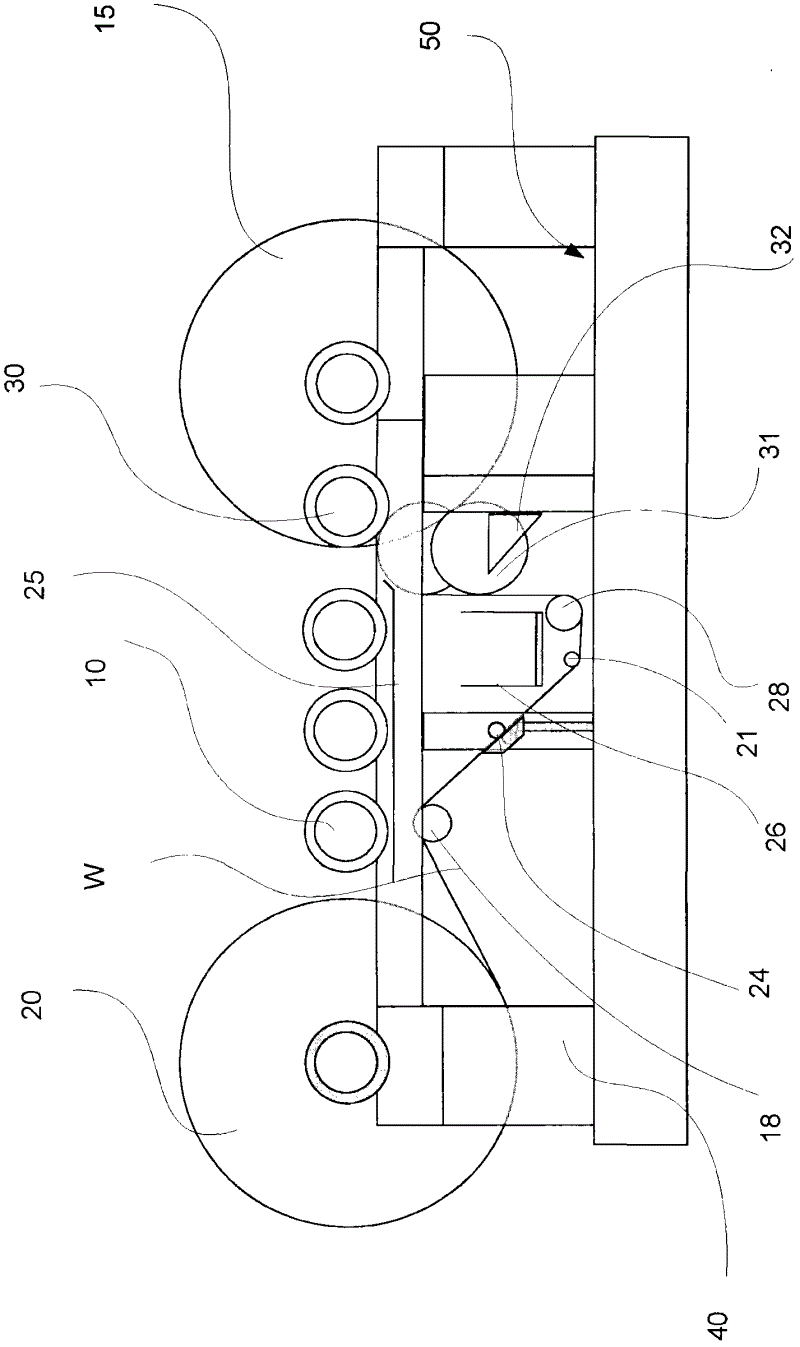

[0041] exist figure 1 with figure 2 Two different intermediate winders according to the prior art are shown in . The intermediate winder typically includes an unwinder 20 , an edge cutting unit 24 and a coiler 30 . The machine roll 15 to be processed in the intermediate winder is conveyed to the unwinder 20 and from there the web W is directed to an edge cutting unit 24 and then to a reel 30 comprising a winding drum 31. The winding shaft emptied by the unwinder 20 is lifted by means of the transport device 22 onto the winding shaft support 25 placed above the intermediate winder and on the track of the winding shaft support or correspondingly along the track The winding shaft 10 is transported for reuse on the coiler 30 . Adjacent to the edge cutting unit 24 is provided an operating platform 26 where the control personnel can obse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com