Plastic concrete for cutoff wall

A technology of plastic concrete and anti-seepage wall, which is applied in the field of plastic concrete for anti-seepage walls and plastic concrete for anti-seepage walls with high content of fly ash, can solve the problem that the performance indicators such as the elastic modulus and impermeability of plastic concrete can not be reached. To the general technical indicators of plastic concrete for anti-seepage walls, the decline of early strength of plastic concrete, and the decline of plastic concrete cohesion, etc., to achieve the effect of being conducive to pumping construction, improving water retention performance, and reducing cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

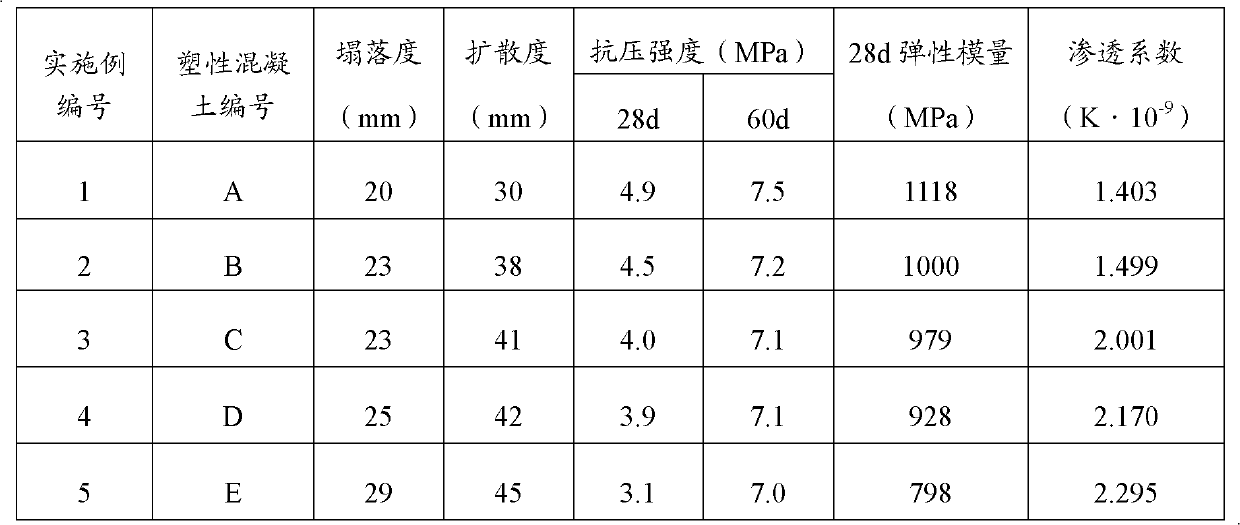

Examples

Embodiment 1

[0022] Calculated per cubic meter of plastic concrete, mix 315kg of water, 34.2kg of bentonite, 85.5kg of clay, 0.648kg of polycarboxylate superplasticizer, 119.7kg of cement, 102.6kg of third-grade fly ash, 698kg of sand, and 787kg of gravel, and stir to prepare Obtain plastic concrete A.

[0023] The water-binder ratio in the above raw materials is 0.92.

Embodiment 2

[0025] Calculated per cubic meter of plastic concrete, 315kg of water, 34.2kg of bentonite, 85.5kg of clay, 0.648kg of polycarboxylate superplasticizer, 102.6kg of cement, 50kg of primary fly ash, 69.7kg of secondary fly ash, and 698kg of sand , 787kg of stones were mixed and stirred to prepare plastic concrete B.

[0026] The water-binder ratio in the above raw materials is 0.92.

Embodiment 3

[0028] Calculated per cubic meter of plastic concrete, mix 315kg of water, 34.2kg of bentonite, 85.5kg of clay, 0.648kg of polycarboxylate superplasticizer, 85.5kg of cement, 136.8kg of secondary fly ash, 698kg of sand, and 787kg of gravel, and stir to prepare Obtain plastic concrete C.

[0029] The water-binder ratio in the above raw materials is 0.92.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com