Preparation method of nickel threonine

A technology of threonine and nickel sulfate, which is applied to the preparation of organic compounds, chemical instruments and methods, and the preparation of cyanide reactions, can solve the problems of ineffective absorption and utilization by animals, low absorption and utilization, and environmental pollution, and achieve the goal of extending The effect of long-term use, low production cost, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

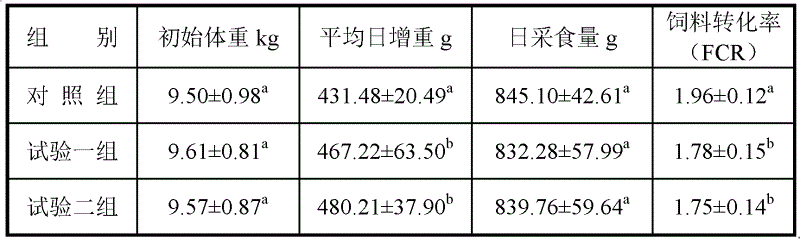

Examples

Embodiment 1

[0026] In this embodiment, nickel sulfate or nickel sulfate crystal hydrate and threonine aqueous solution are mixed and reacted at a reaction temperature of 40° C. to 100° C. for 1.5 hours to 3.5 hours to obtain a reaction product.

[0027] By the basic principles and laws of chemical reactions, we can preliminarily determine that the reaction product may be a new threonine chelate—nickel threonine; The analysis of the content, as well as the structure analysis of conventional infrared analysis and X-ray diffraction, further confirm that the reaction product is the nickel threonine of the present invention.

[0028] Wherein, the molar ratio of nickel sulfate or the crystalline hydrate of nickel sulfate to threonine is (0.8~1.1): 1, and when the mass concentration of threonine aqueous solution is 15%~25%, the reaction is complete, the raw materials are fully utilized, and the preparation The threonine nickel has high purity, less impurities and better effect.

[0029] The obt...

Embodiment 2

[0034] In Example 2, nickel threonine of the present invention was prepared through the following reaction steps: Measure 100mL of water and pour it into a 250mL reaction cup, turn on the stirring device, put 23.8g of threonine into the reaction cup at room temperature, and heat to 50°C Afterwards (all the materials are dissolved), 52.6g of nickel sulfate hexahydrate is added thereto, reacted at a constant temperature of 60°C for 2.5 hours, and the reaction product is evaporated to dryness at a temperature of 90°C and then put into a tray for crystallization, and then sent to a drying room for drying. The drying temperature is controlled at 100°C, and finally the finished product is obtained by pulverizing. By carrying out the analysis of nickel and threonine content to the finished product after the above reaction, and the structural analysis of conventional infrared analysis and X-ray diffraction, it is confirmed that the reaction product is the nickel threonine of the presen...

Embodiment 3

[0037] This Example 3 prepares nickel threonine of the present invention through the following reaction steps: take 1250 kg of water and pour it into the reactor, turn on the stirring device, put 297.5 kg of threonine into the reactor at normal temperature, and then heat it to 55 ° C. Put 650.5kg of nickel sulfate hexahydrate into it, react at a constant temperature of 90°C for 3 hours, evaporate the reaction product to dryness at 95°C, put it into a tray for crystallization, send it to a drying room for drying, the drying temperature is controlled at 105°C, and finally pulverize The nickel threonine finished product is prepared. By carrying out the analysis of nickel and threonine content to the finished product after the above reaction, and the structural analysis of conventional infrared analysis and X-ray diffraction, it is confirmed that the reaction product is the nickel threonine of the present invention, and the molecular formula of the finished product is:

[0038] [C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com