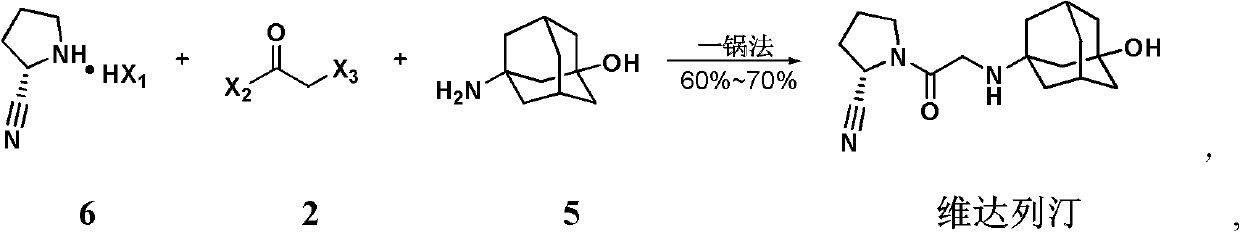

Process for preparing Vildagliptin by one-pot method

A process and a selected technology, applied in the field of one-pot preparation of vildagliptin, can solve the problems of many functional groups, many by-products, low yield and the like, and achieve the effect of simple and convenient process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

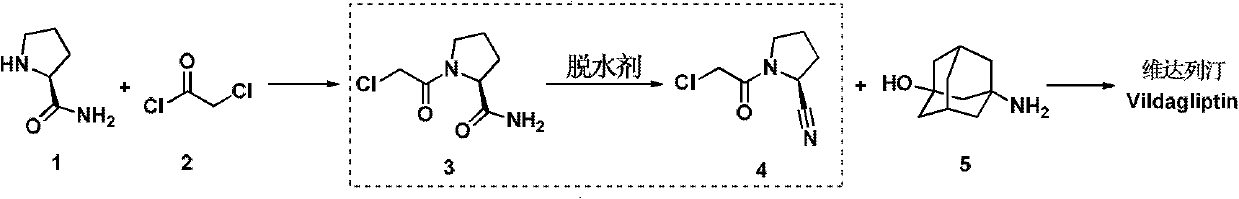

Method used

Image

Examples

Embodiment 1

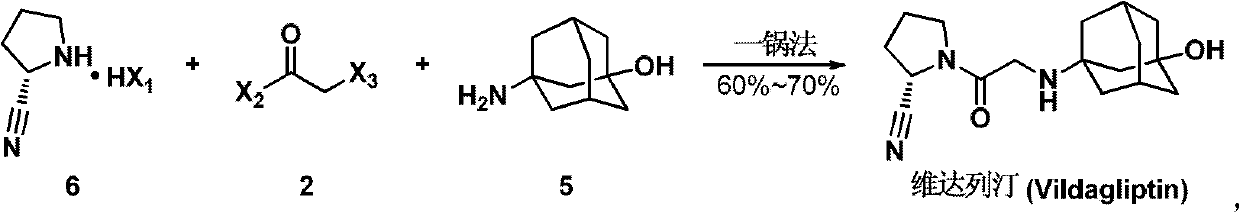

[0022] The preparation one of embodiment 1 vildagliptin

[0023] Add 8 mL of chloroacetyl chloride 2 and 100 mL of anhydrous dichloromethane into a 1 L three-necked flask under the protection of nitrogen. Under the condition of cooling in an ice bath, 21 grams of (S)-pyrrole-2-cyano trifluoroacetate 6 was added dropwise in this reaction mixture (by the known literature Journal of Medicinal Chemistry, 2009, 52 (21) , 6672-6684) and 33 milliliters of triethylamine in 200 milliliters of anhydrous dichloromethane solution, after the dropwise addition, the reaction solution was raised to room temperature and continued to stir for 6 to 24 hours. Add 1.8 grams of tetrabutylammonium iodide to the reaction solution, then add 17 grams of 3-amino-1-adamantanol 5 and 20 milliliters of triethylamine dropwise in 100 milliliters of anhydrous dichloromethane solution, after the dropwise addition, the reaction solution was continuously stirred at 30-40° C. for 72 hours. Add 500 ml of water t...

Embodiment 2

[0026] The preparation two of embodiment 2 vildagliptin

[0027] Add 8.7 mL of bromoacetyl bromide 2 and 100 mL of anhydrous chloroform into a 1 L three-necked flask under the protection of nitrogen. Under the condition of cooling in an ice bath, 21 grams of (S)-pyrrole-2-cyano trifluoroacetate 6 was added dropwise in this reaction mixture (by the known literature Journal of Medicinal Chemistry, 2009, 52 (21) , 6672-6684 made) and 200 ml of anhydrous chloroform solution of 40 ml of diisopropylethylamine, after the dropwise addition, the reaction solution rose to room temperature and continued stirring for 10 hours. Add 1.8 grams of tetrabutylammonium iodide to the reaction solution, and then add 17 grams of 3-amino-1-adamantanol 5 and 20 milliliters of diisopropylethylamine dropwise to the reaction solution in 100 milliliters without Water chloroform solution, after the dropwise addition, the reaction solution was stirred for 24 hours. Add 500 ml of water to the reaction sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com