Hydraulic transmission device allowing the recovery of energy

A technology of hydraulic transmission device and hydraulic pump, which is applied in the direction of transmission device control, accumulator device, fluid pressure actuation device, etc. It can solve the problems of high cost, complex device, high energy, etc., and achieve simple structure and high energy efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

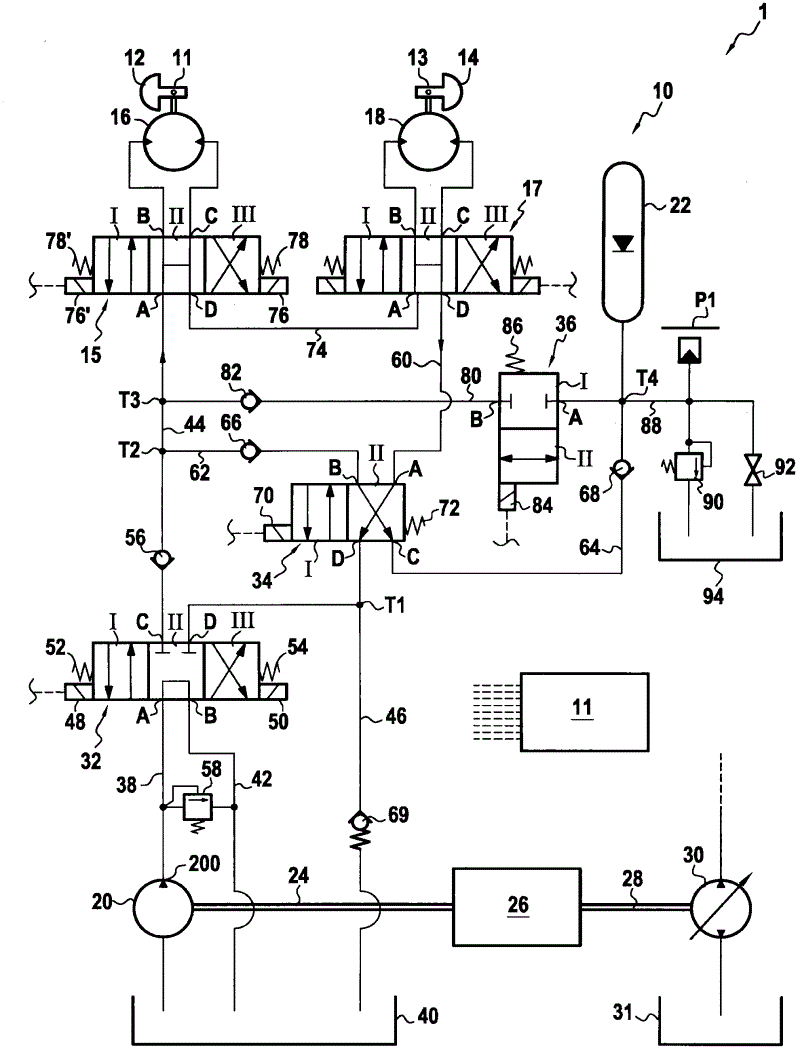

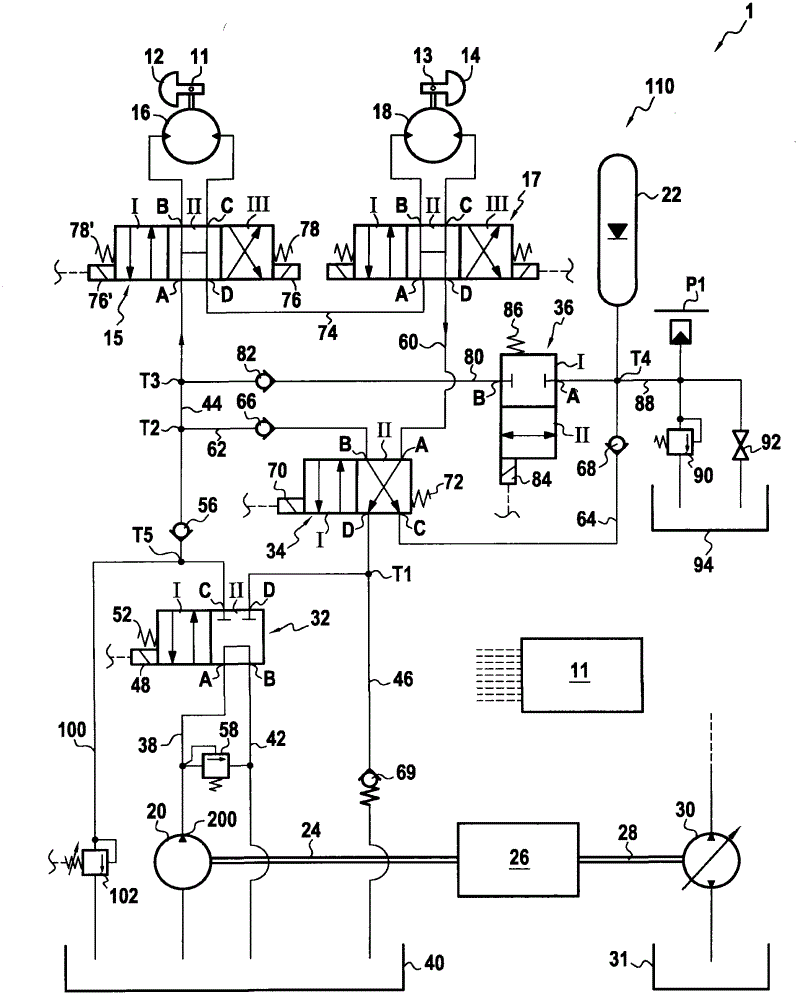

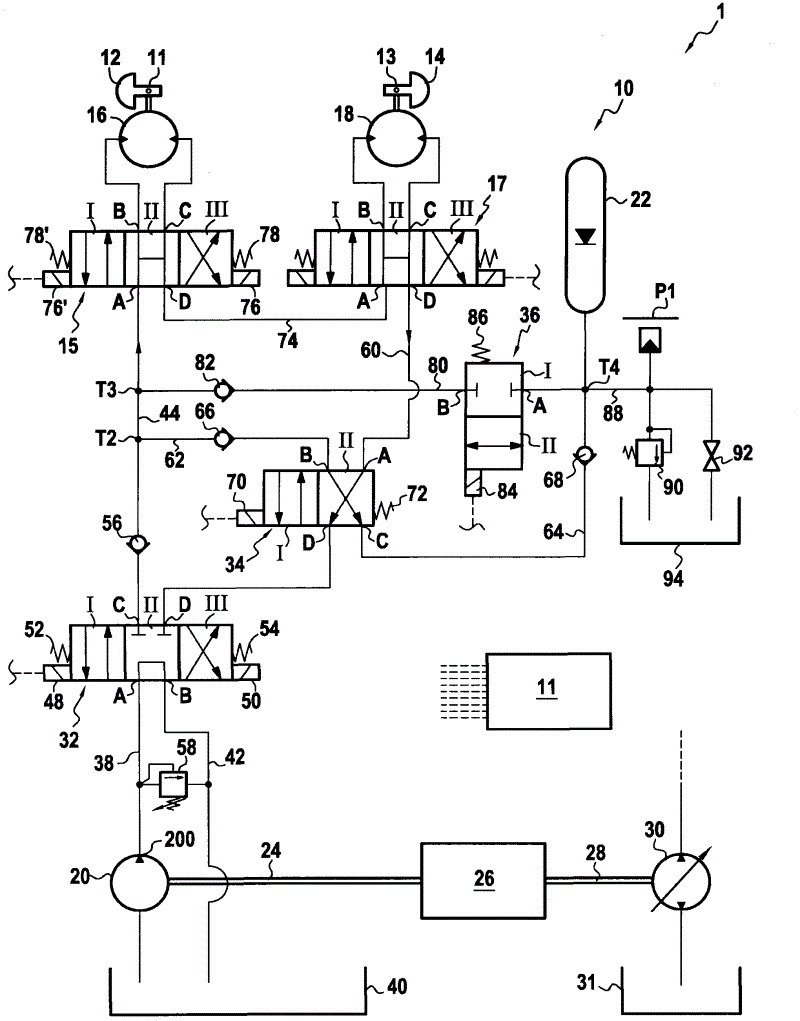

[0083] will now combine figure 1 The hydraulic transmission device 10 according to the present invention in the first embodiment is described.

[0084] The device 10 is a device for driving two eccentric masses 12 and 14 . These eccentric masses or "vibrating masses" are attached to the inside of two pressure rollers arranged respectively at the front and rear of the roller (not shown). These eccentric masses are attached eccentrically to the shafts 11 and 13 of the two press rollers, respectively, so that when the eccentric masses are actuated to rotate about the axes 11 and 13, they can vibrate the press rollers.

[0085]The device 10 associated with the shafts 11 , 13 and the masses 12 , 14 constitutes the assembly 1 according to the invention.

[0086] Device 10 includes:

[0087] Two radial piston hydraulic motors 16 and 18;

[0088] a hydraulic pump 20;

[0089] a fluid accumulator 22 capable of storing and delivering fluid under pressure; and

[0090] A control u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com