Single-point feeding and multipoint spreading device and electric-arc furnace

A spreader and spreading technology, applied in the field of electric arc furnaces, can solve the problems of inability to classify processing, uneven distribution, large space occupation, etc., and achieve the effects of fewer parts, lower plant height, and lower manufacturing and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

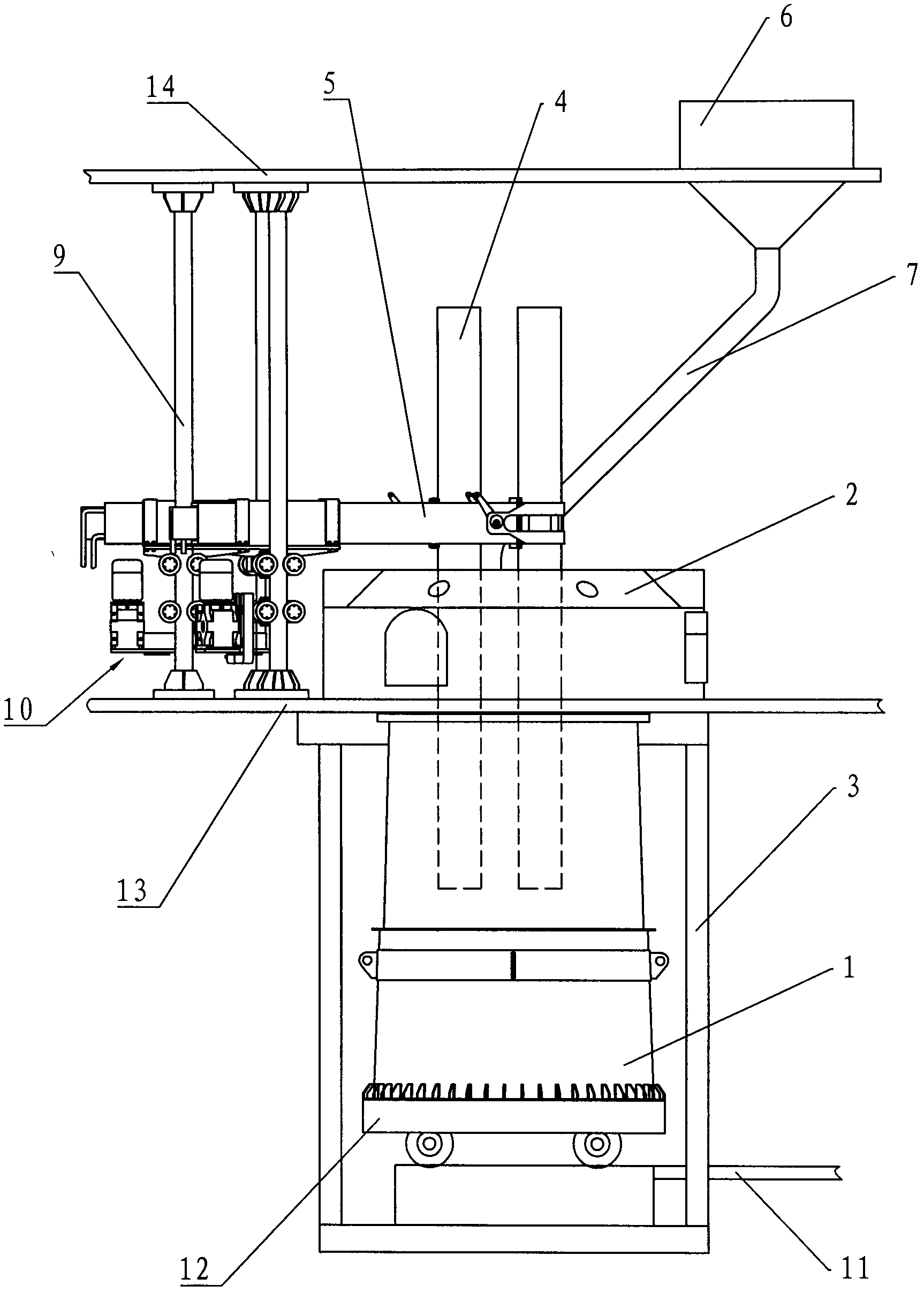

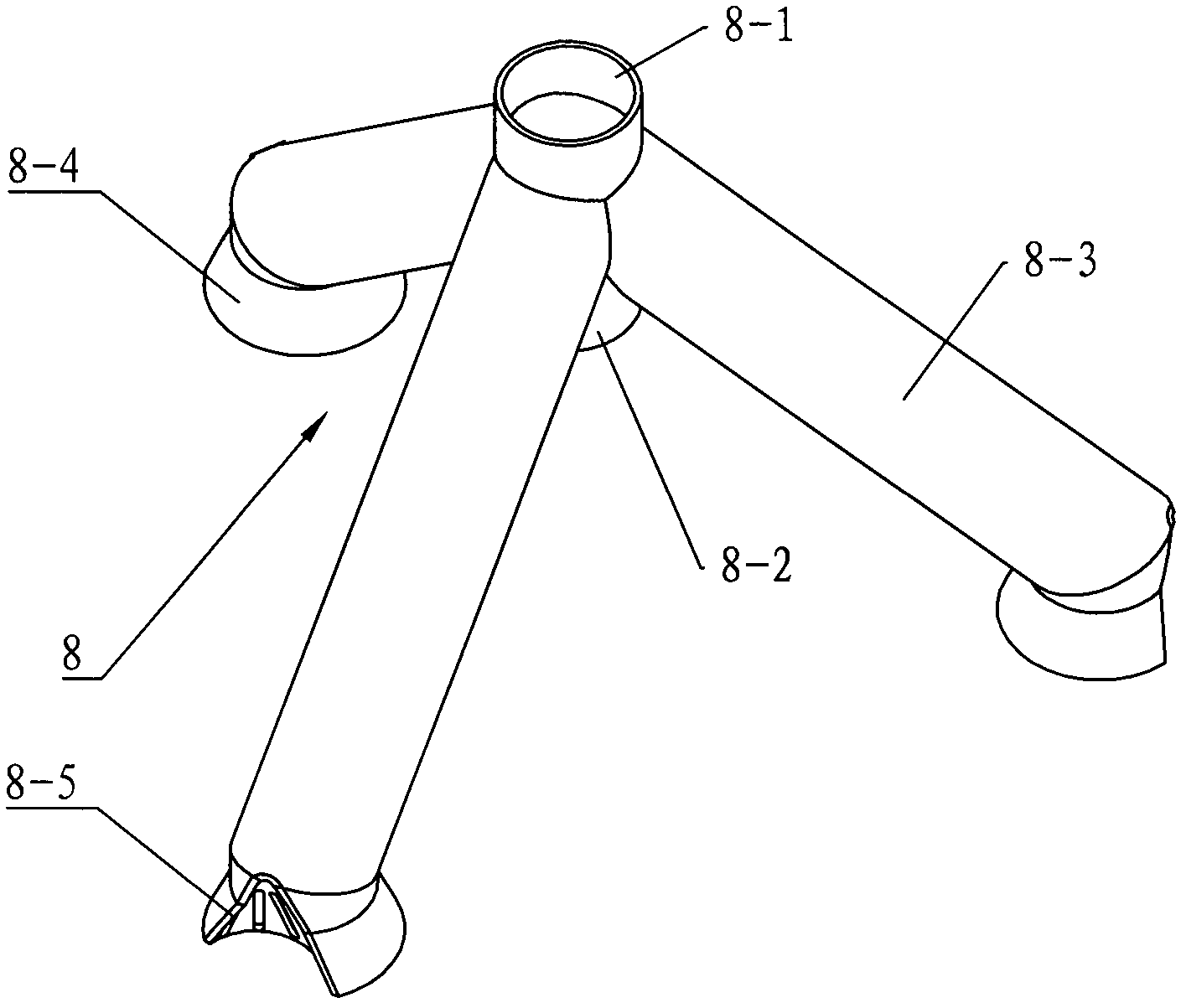

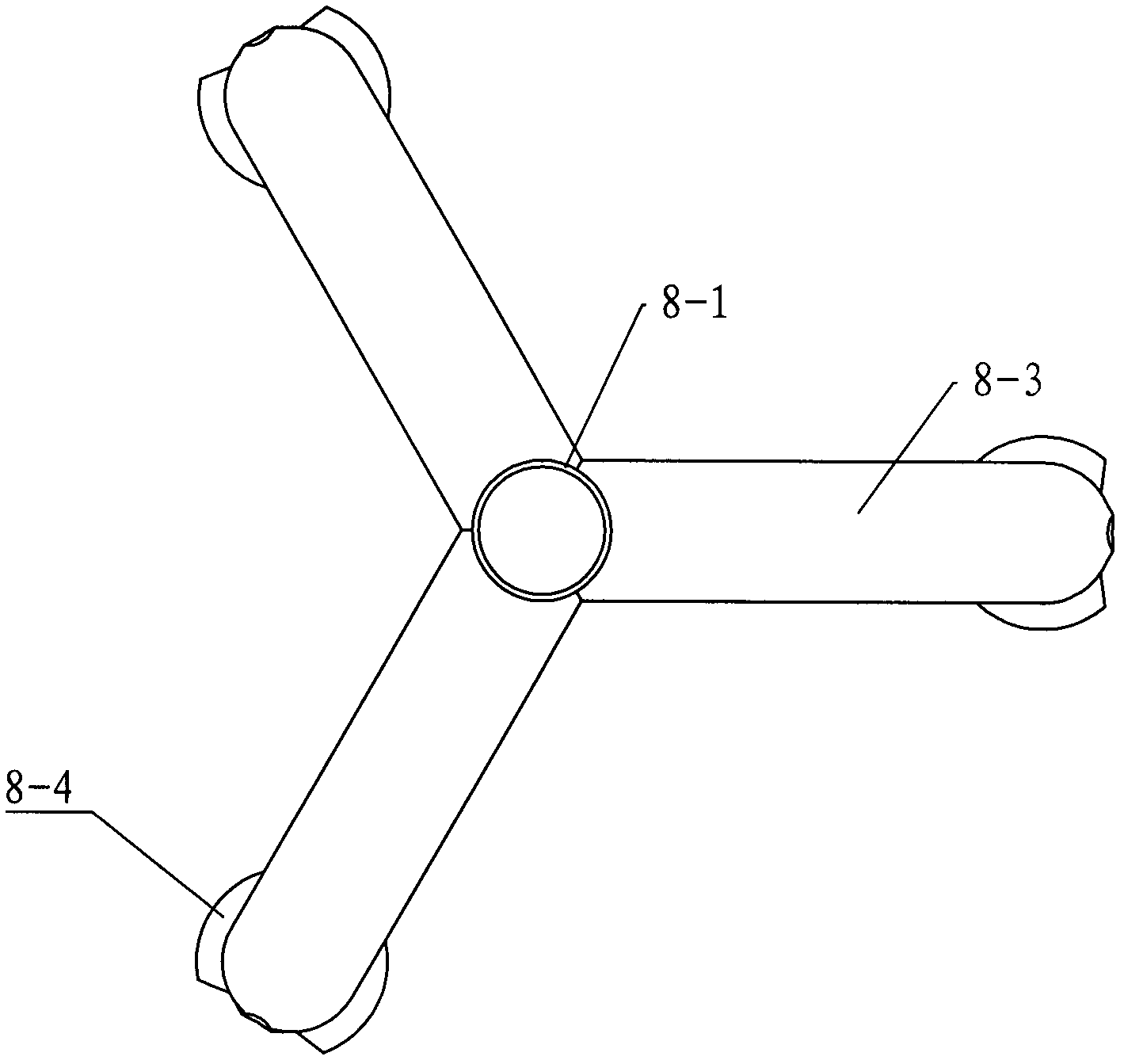

[0039] Such as figure 1 As shown, the electric arc furnace of this embodiment includes a furnace cylinder 1, a furnace cover 2, a furnace cylinder protective frame 3, an electrode 4, a conductive cross arm 5, a silo 6, a material pipe 7, a distributor 8, a cross arm pillar 9, an electrode Lifting control device 10, power supply and transformation system (not shown), water cooling cable (not shown), cooling water system (not shown), electrical control room (not shown).

[0040] The furnace drum 1 is arranged in the furnace drum protection bracket 3. The furnace drum 1 of this embodiment is placed on a trolley 12 running along the guide rail 11, and the furnace drum 1 is sent into the furnace drum protection frame 3 by the trolley 12 or from Move out in the furnace protection frame 3. The top of the furnace drum protection bracket 3 is an operating platform 13, the furnace cover 2 is placed on the operating platform 13 and can cover the upper opening of the furnace drum 1, the ...

Embodiment 2

[0045] Such as Figure 11 As shown, the difference between this embodiment and Embodiment 1 lies in that the plane of the outlet of the material distribution inclined tube 8-2 of this embodiment is set horizontally.

Embodiment 3

[0047] Such as Figure 12 and Figure 13 As shown, the difference between this embodiment and Embodiment 2 is that the grading distribution plate 8-5 of this embodiment is a trapezoidal flat plate, and the grading distribution plate 8-5 is arranged parallel to the vertical line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com