Pressure chamber for rock-soil rheological test

A rheological test and pressure chamber technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problems of reference value discount, uneconomical, large manpower and financial resources, etc., to achieve reference value Large, improve the application level, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

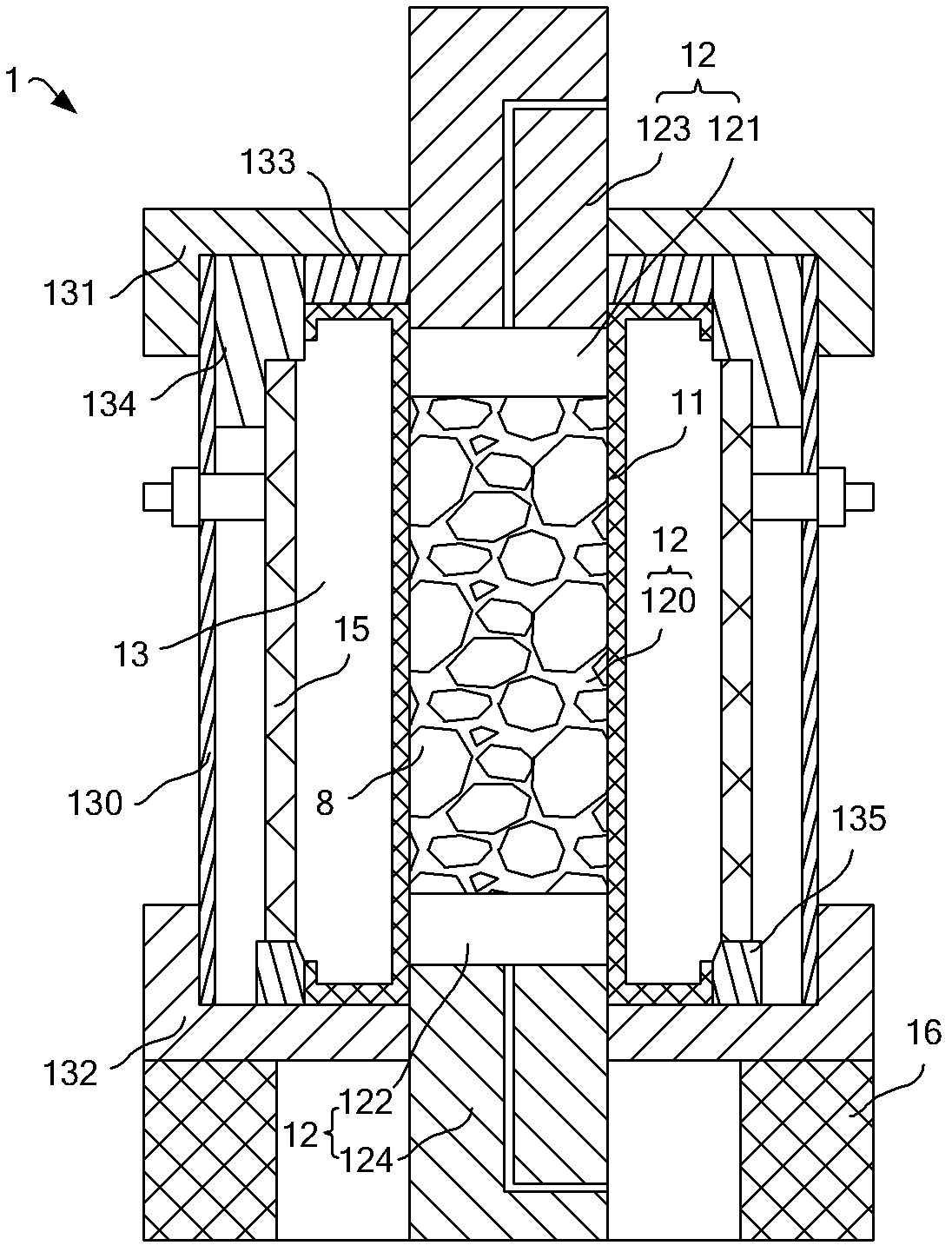

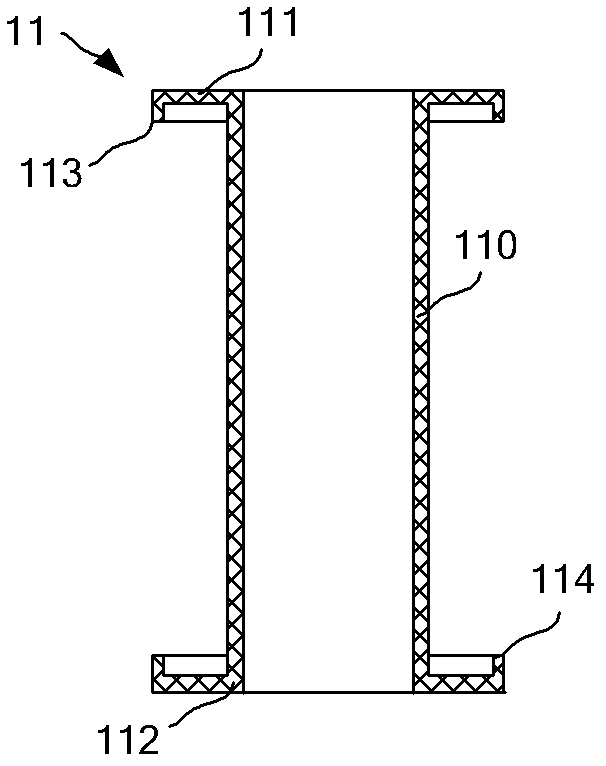

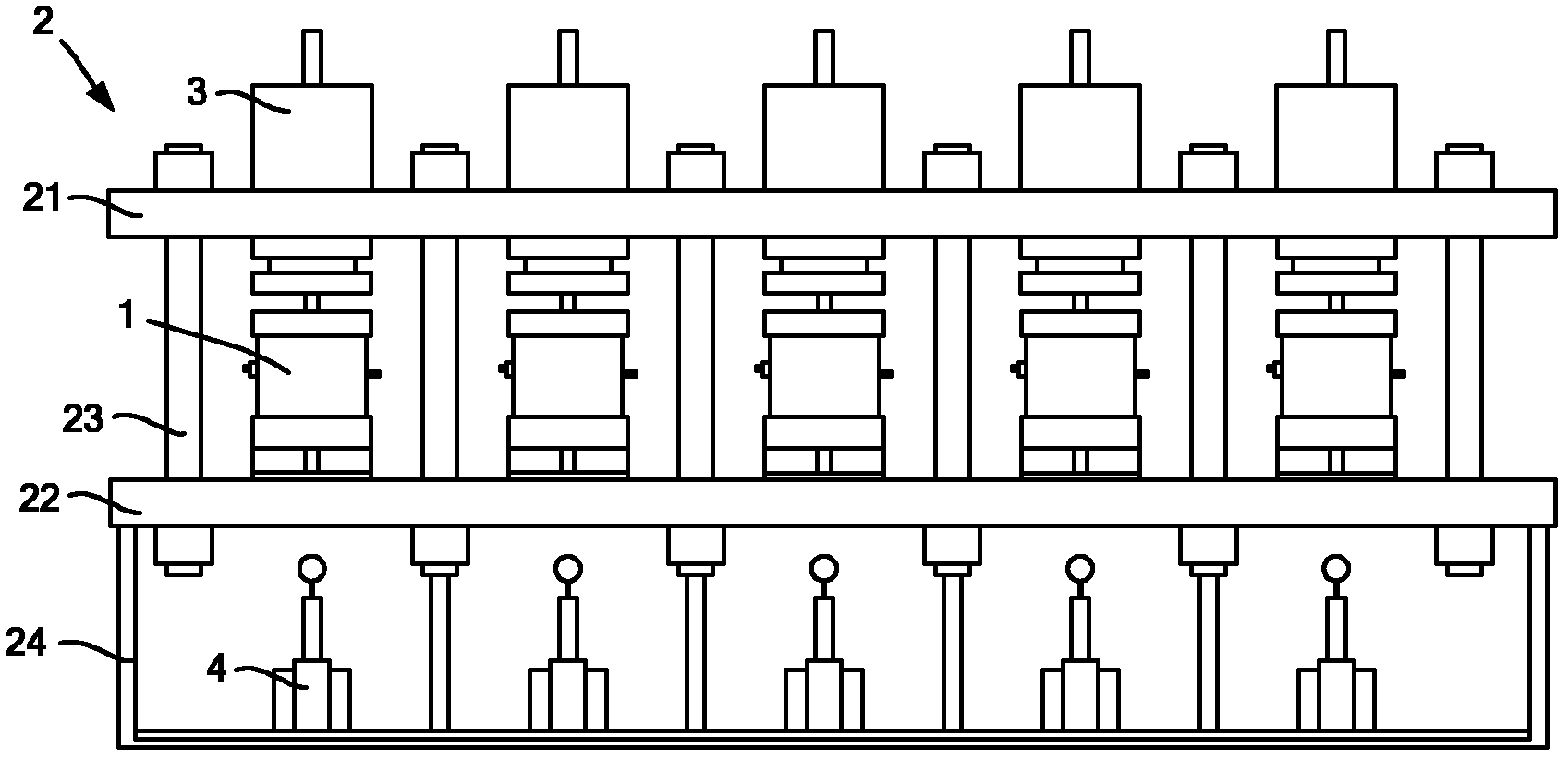

[0019] The rock-soil rheological test method is to simulate different stress field environments of the rock and soil by applying pressure to the rock-soil test pieces set in the pressure chamber, and then by detecting the change parameters of the rock-soil test pieces in the above-mentioned environment to simulate the actual rock-soil Evaluation of soil changes under different stress field environments. In the present invention, the axial pressure and radial pressure of the rock-soil test piece located in the pressure chamber are absolutely isolated, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com