Light-emitting diode (LED), backlight module and liquid crystal display device

A consistent, inner-cavity technology, applied to lighting devices, components of lighting devices, optics, etc., can solve problems such as unfavorable light dispersion, achieve the effects of increasing contact area, reducing electrode oxidation, and expanding the output angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

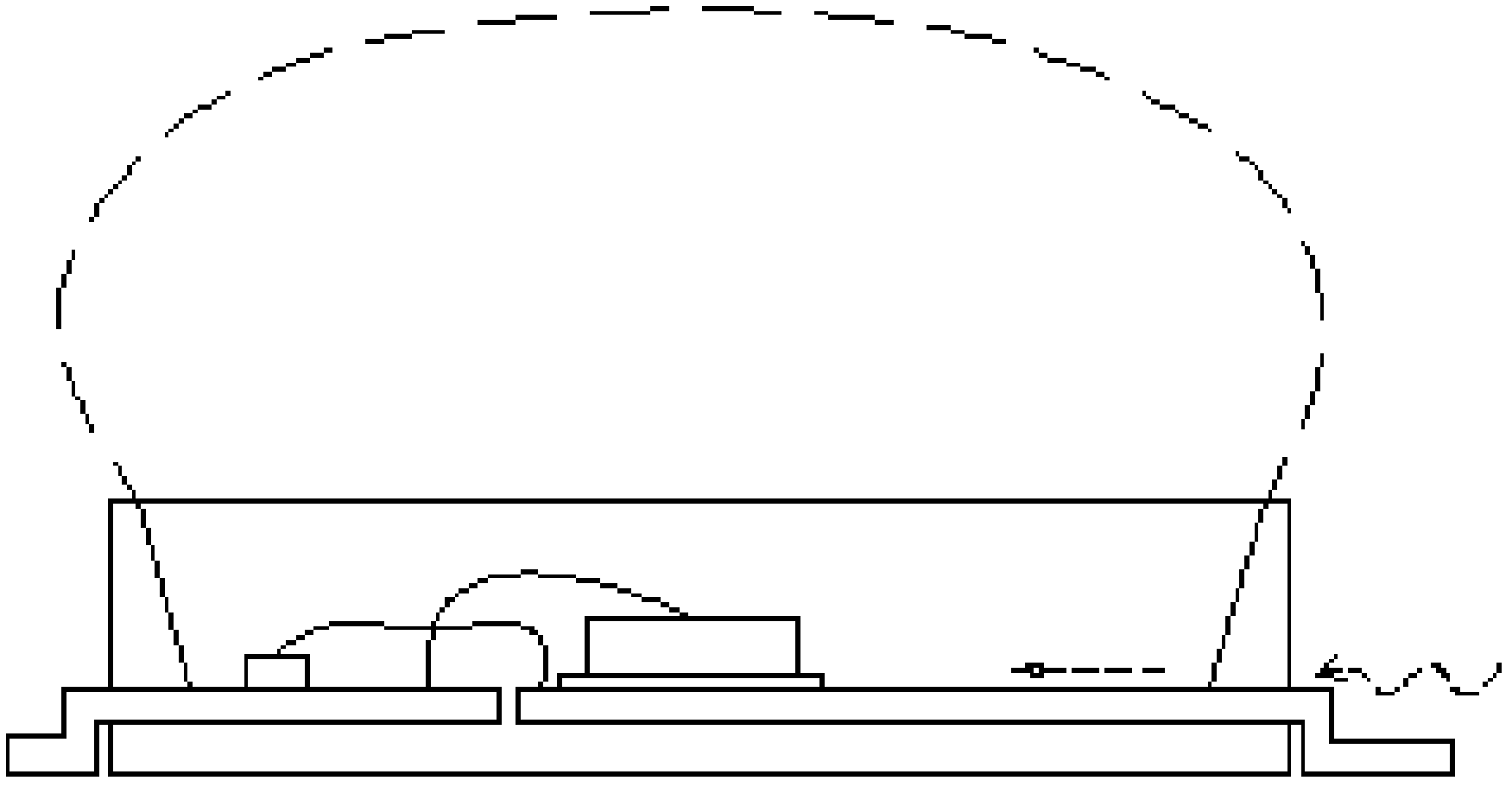

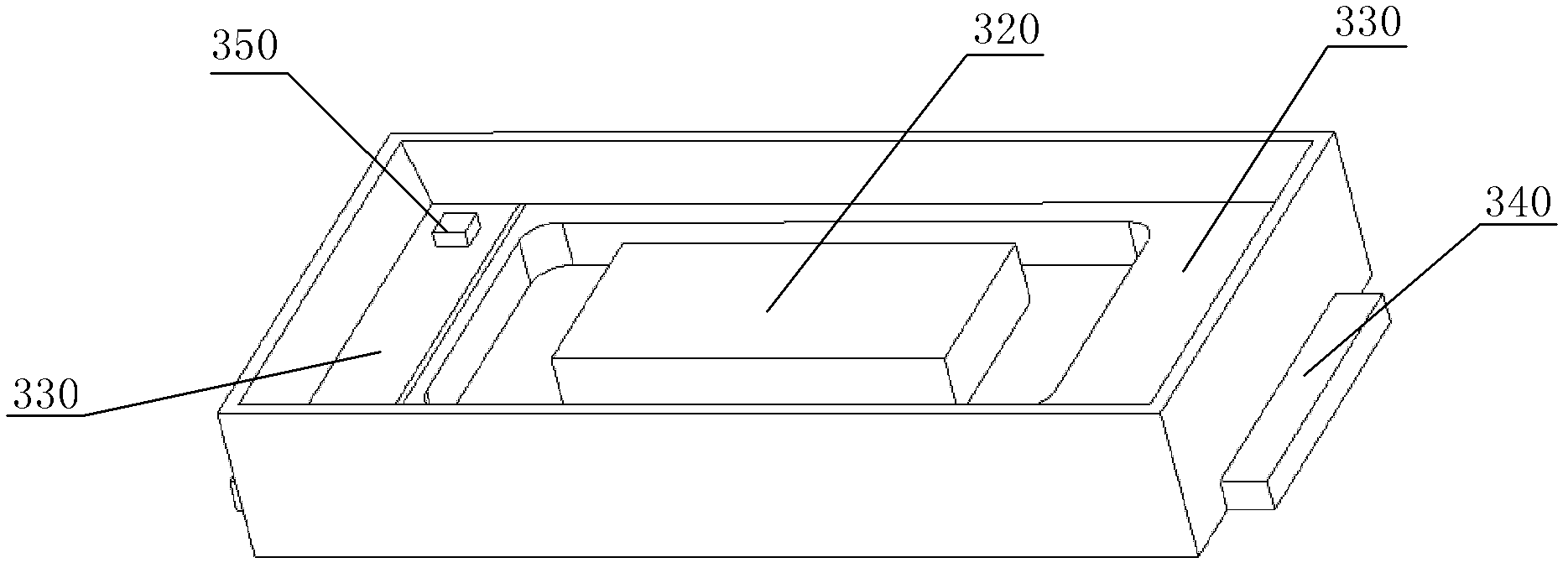

[0033] Such as Figure 6 As shown, one of the two side walls adjacent to the stepped surface is provided with a first slope 310, and the acute angle angle between the first slope 310 and the bottom plane of the inner cavity is in the range of 0.5° to 89°, Preferably, it is 30° to 60°. The electrodes 330 may be disposed on the two short side walls of the inner chamber, and correspondingly, the first slope 310 is disposed on the long side walls of the inner chamber. Certainly, the electrodes 330 may also be disposed on the two long side walls of the inner chamber, and correspondingly, the first slope 310 is disposed on the short side walls of the inner chamber.

[0034] In order to prevent the chip from being broken down by static electricity, a zener tube can be connected in series on one of the electrodes, and the zener tube is arranged on the step surface, which can prevent the zener tube from absorbing light.

Embodiment 2

[0036] Such as Figure 7 As shown, the two side walls adjacent to the step surface are provided with slopes, which are the first slope 310 and the second slope 311 respectively, and the acute angle angle between the slope and the inner cavity bottom plane is in the range of 0.5° to 89° Between, preferably, 30° to 60°. The electrodes 330 may be disposed on two short side walls of the inner chamber, and correspondingly, the first slope 310 and the second slope 311 are disposed on the long side walls of the inner chamber. Certainly, the electrodes 330 may also be arranged on the two long side walls of the inner cavity, and correspondingly, the first inclined surface 310 and the second inclined surface 311 are arranged on the short side walls of the inner cavity.

[0037] In order to prevent the chip from being broken down by static electricity, a zener tube can be connected in series on one of the electrodes, and the zener tube is arranged on the step surface, which can prevent ...

Embodiment 3

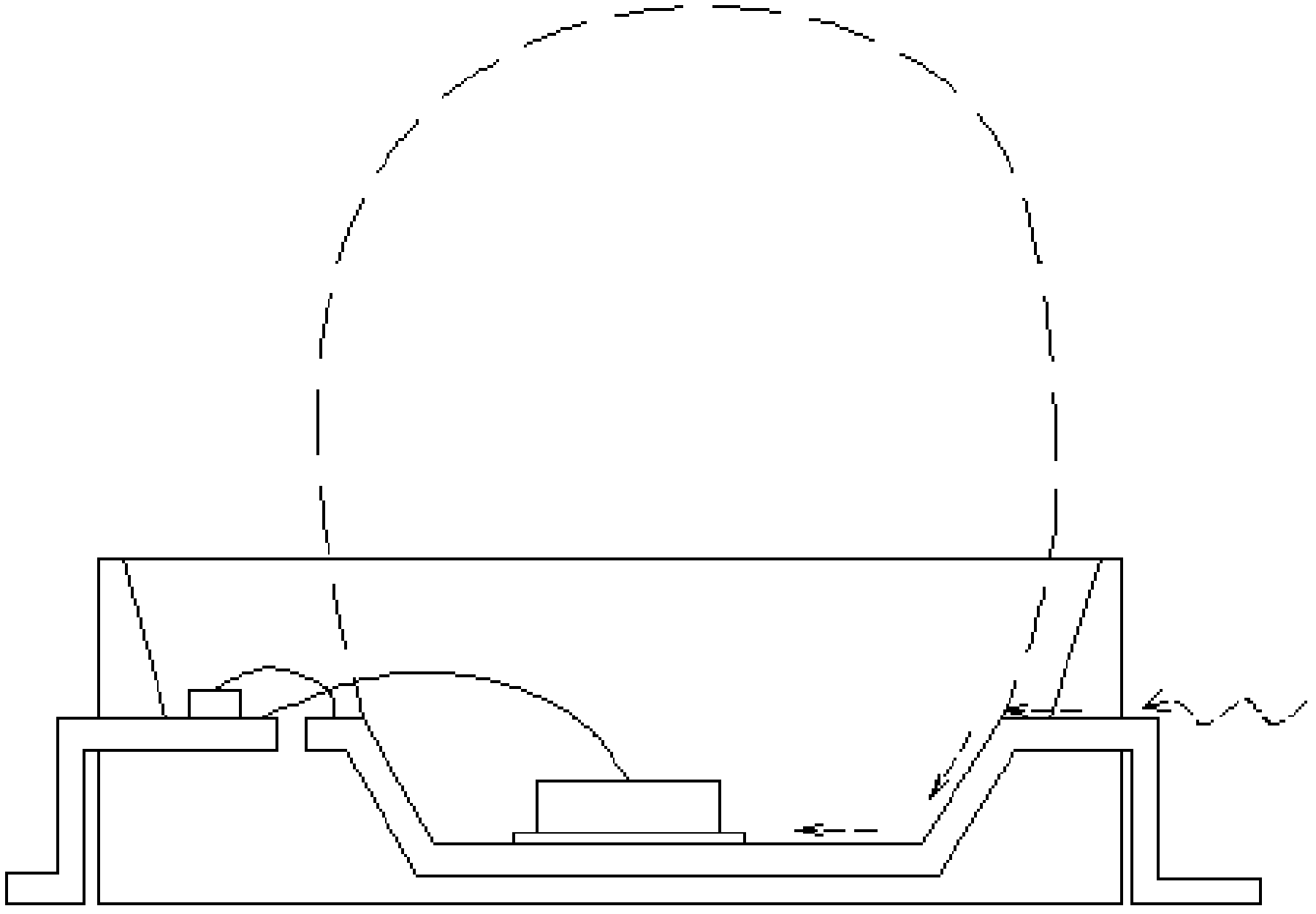

[0039] Such as Figure 8 As shown, one electrode 330 provided with a zener tube 350 protrudes to form a stepped surface 331 at the bottom of the inner cavity, while the other electrode 330 is arranged at the bottom of the inner cavity, and the corresponding side of the inner cavity is also provided with a slope, A third slope 360 is formed, and the acute angle between the slope and the bottom plane of the cavity is in the range of 0.5° to 89°, preferably 30° to 60°. This embodiment can be combined with any one of the first and second embodiments above, especially with the second embodiment, so that three of the four side walls of the inner cavity are provided with slopes to form a first The inclined surface 310, the second inclined surface 311, and the third inclined surface 360 can ensure the maximum range of light emission.

[0040] The electrodes 330 are arranged on the two short side walls of the inner cavity, and correspondingly, the first inclined surface 310 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com