Annular prestressed stranded wire reeving trolley and reeving method

A technology of prestressed steel strand and cable trolley, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of lack of construction experience in prestressed lining of large-scale water diversion tunnels, inability to adapt, and low work efficiency. , to achieve the effect of convenient processing and maintenance, improved efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

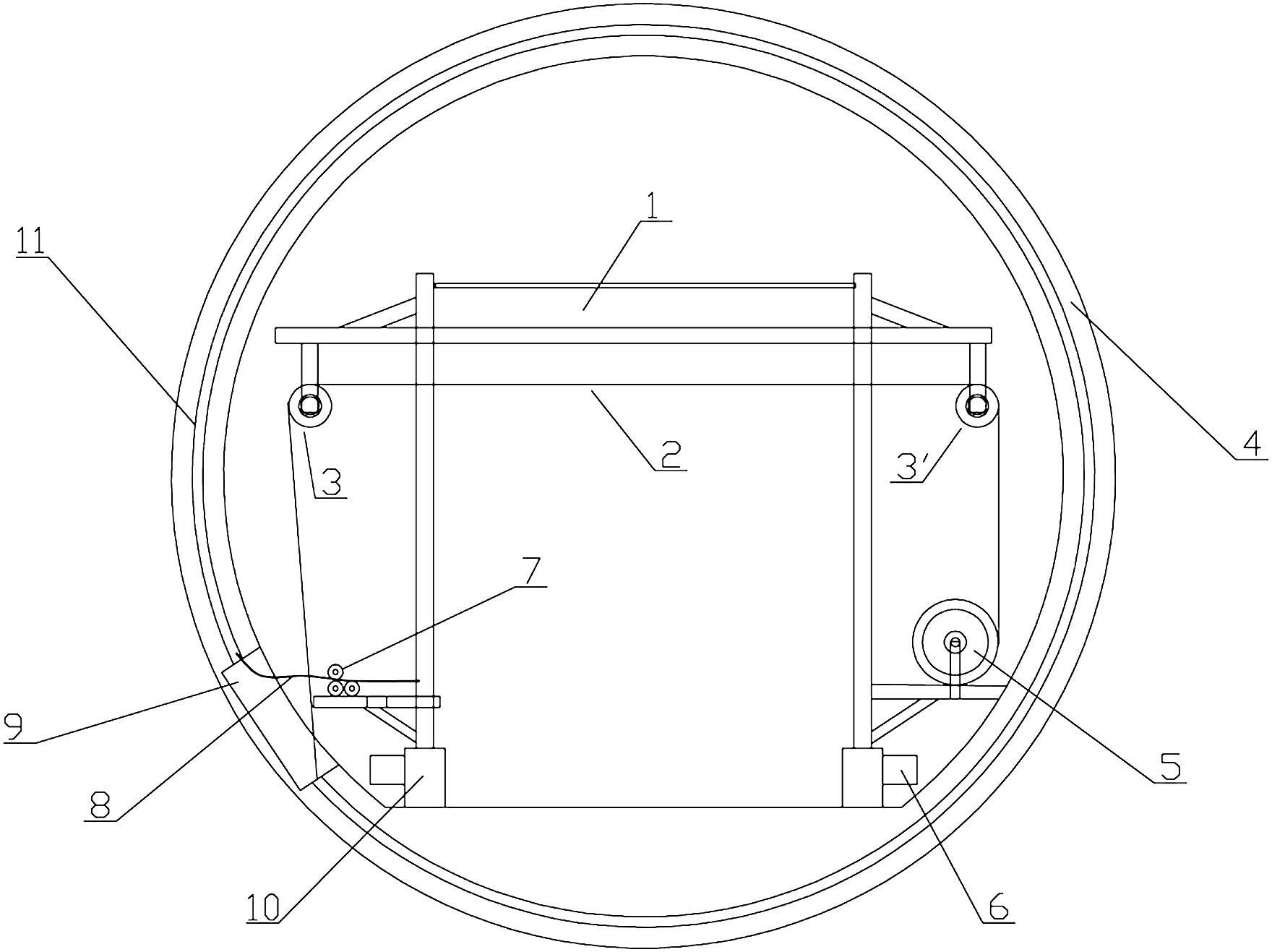

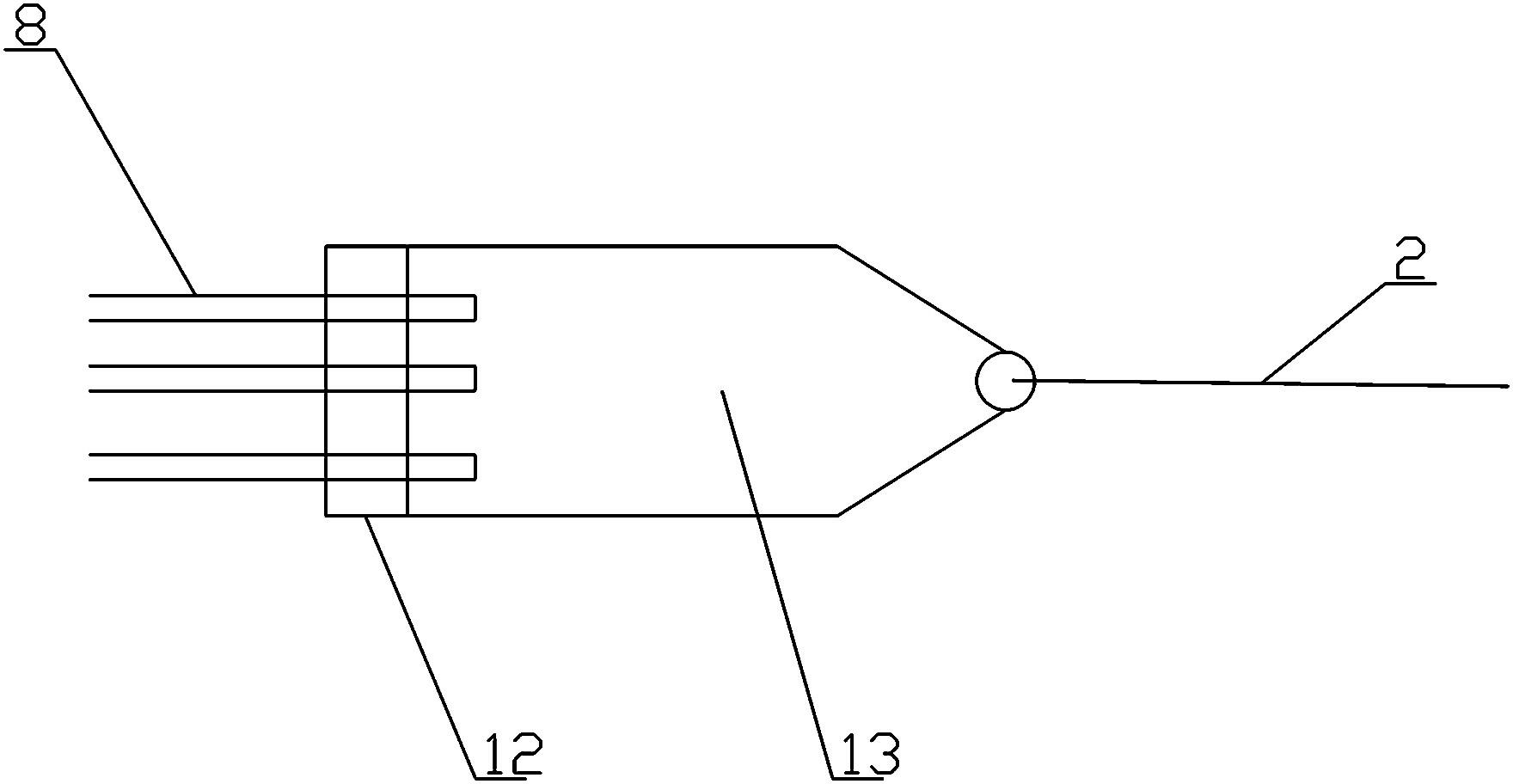

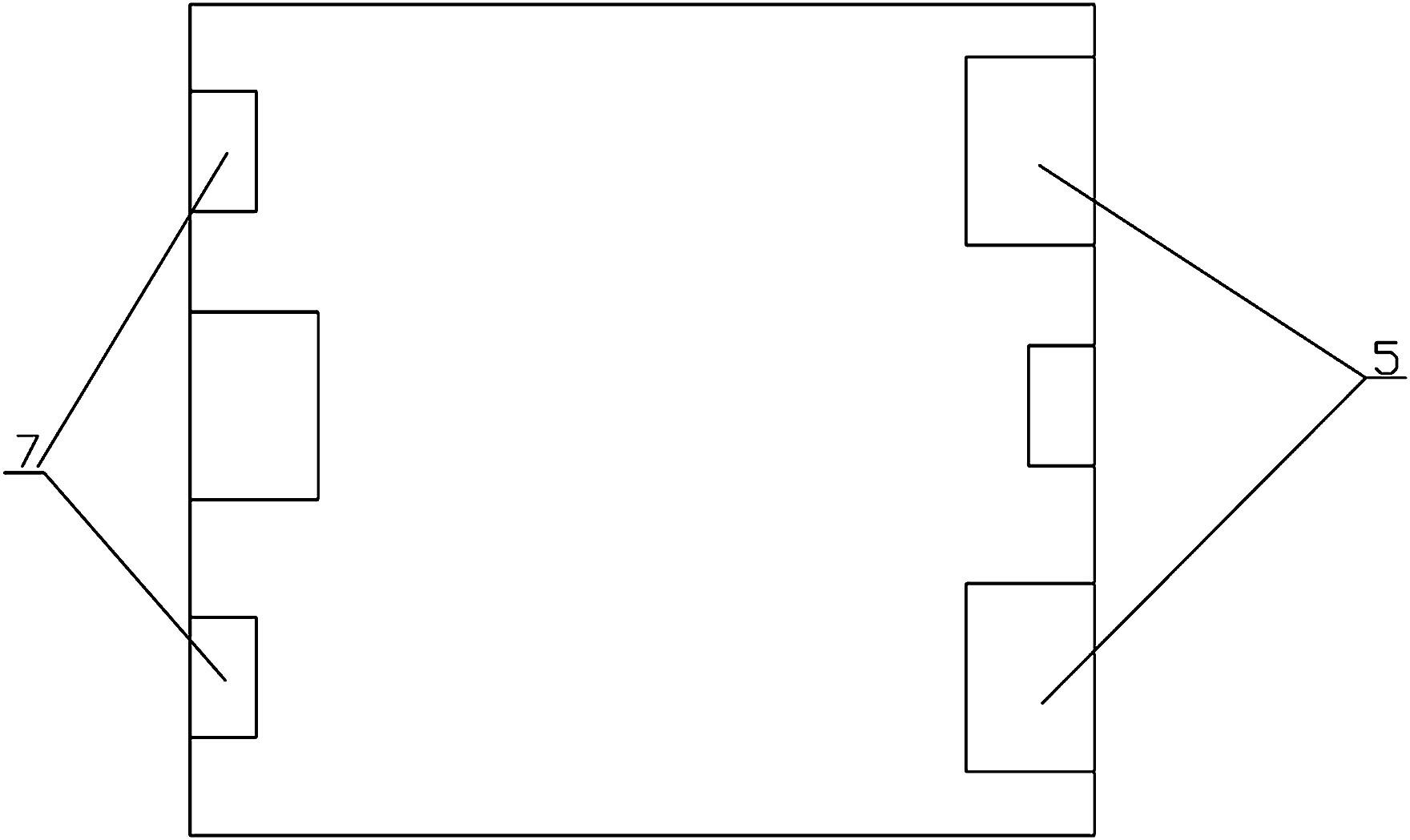

[0031] Such as figure 1 Among them, an annular prestressed steel strand threading trolley includes a platform 1, at least one set of first reversing pulleys 3 and second reversing pulleys 3' are arranged on both sides of the upper part of the platform 1, and the lower part of the platform 1 At least one winch 5 is provided on one side, and a pressure roller device 7 is correspondingly provided on the other side of the lower part of the stand 1 . Wherein, the pressure roller device 7 is used for initially utilizing the frictional force between the roller and the single steel strand 8 and the hardness and flexibility of the single steel strand 8 itself to penetrate the single steel strand 8 into the corrugated Inside the tube 11.

[0032] In an optimized solution, a space for passage is provided in the middle of the platform 1 . The platform 1 adopts a "gate"-shaped structure through the middle, so that the middle of the tunnel can pass through during the cable threading proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com