Arrangement with combustion engine and planetary gear attached to same

A technology of layout structure and planetary transmission, applied in transmission, machine/engine, gear transmission, etc., can solve problems such as not being able to optimally transmit force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

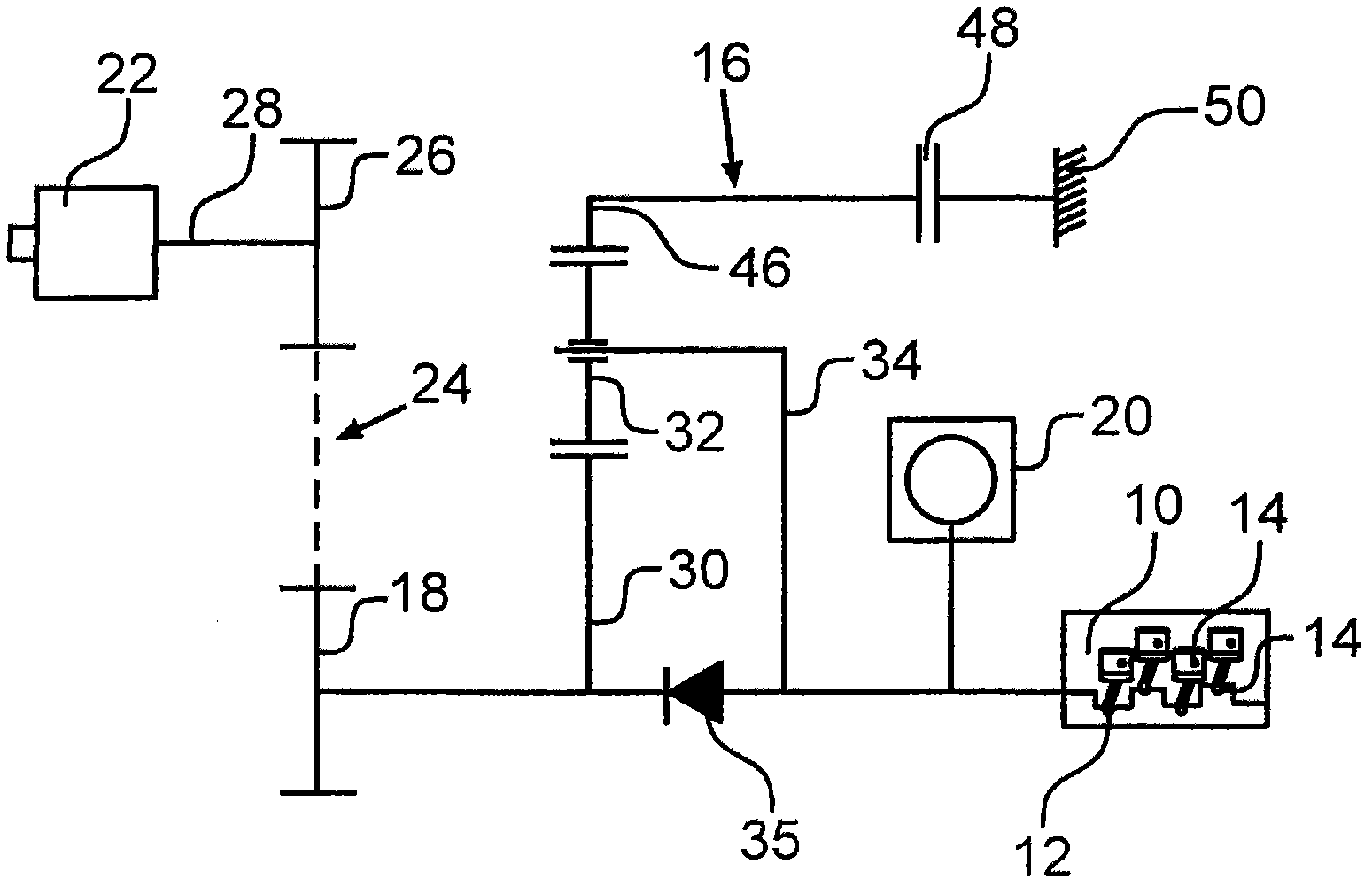

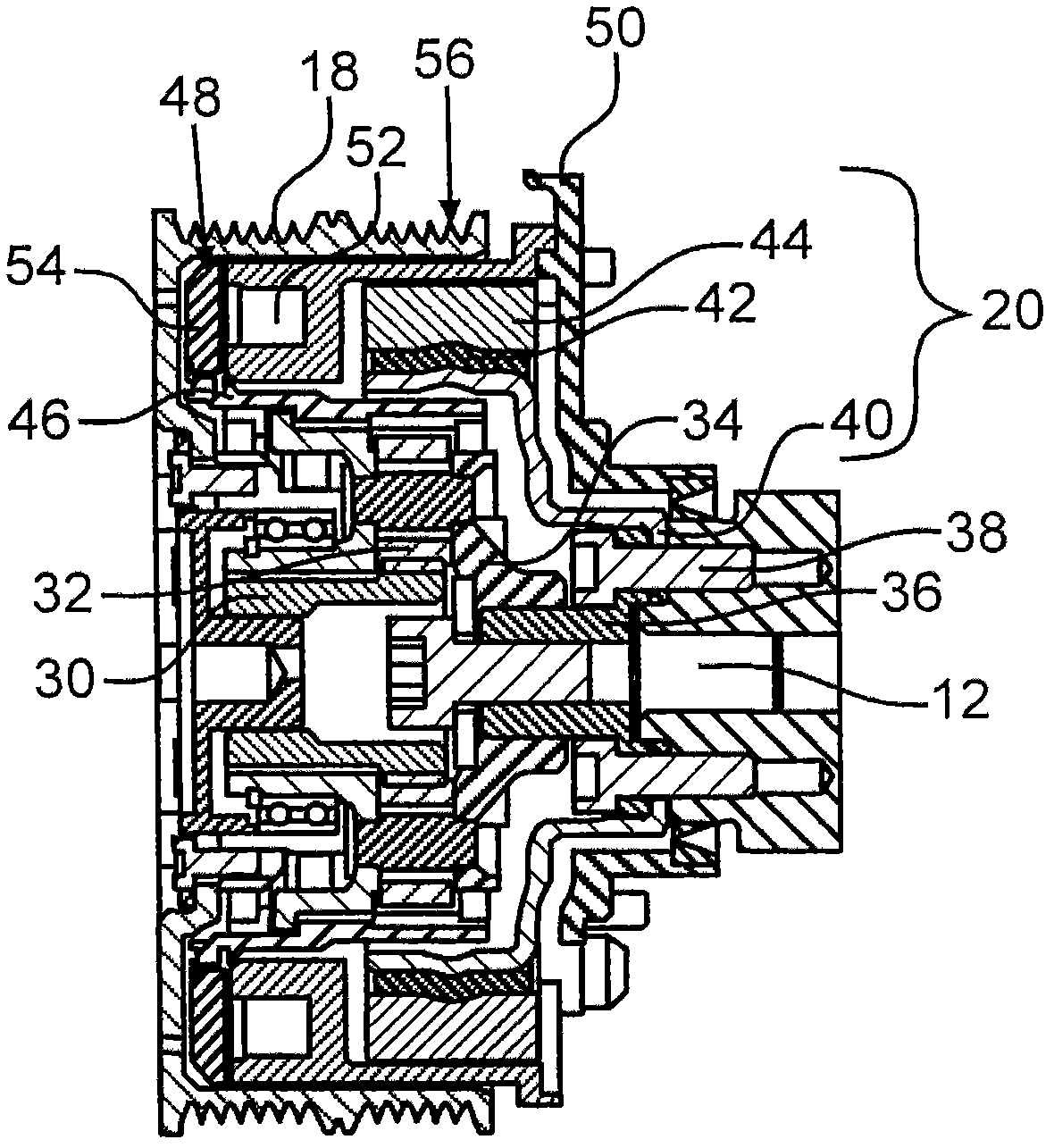

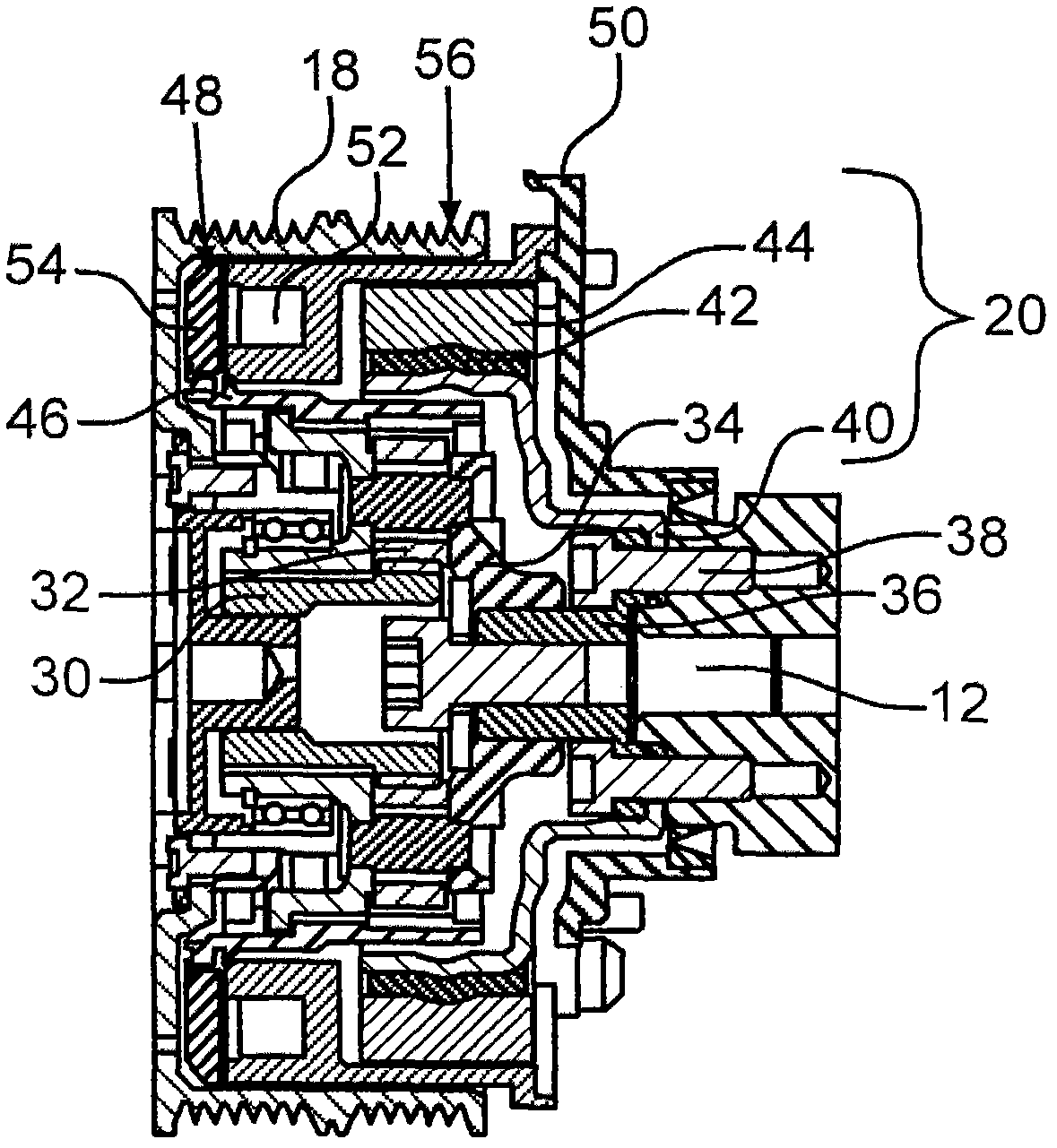

[0019] An arrangement 16 is coupled to an engine 10 comprising a crankshaft 12 which is caused to turn by the movement of a reciprocating piston within a combustion chamber 14, the arrangement comprising a planetary transmission connected to a pulley 18 and having a damping unit 20. The pulley 18 is used to connect a motor 22 via a belt drive 24, the motor includes a pulley 26 which can be rotated by a rotor (not shown) of the motor 22 via a shaft 28.

[0020] The planetary gear comprises a sun gear 30 which is connected to the pulley 18 and meshes with planet gears 32 which are connected to one another via a planet gear carrier 34 . An overrunning clutch 35 is arranged between the planet carrier 34 and the sun gear 30 . The planet carrier 34 is coupled to the crankshaft 12 via a flange 36 . The flange is screwed to the crankshaft 12 via an axial bolt 38 . At the same time, a support plate 40 is clamped between the flange 36 and the crankshaft 12 , on which a rubber ring 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com