Gas permeability test device

A technology of gas permeability and testing equipment, which is applied in the direction of measuring equipment, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problem that the sample cannot be effectively sealed and controlled, the testing process cannot be fully controlled, and multi-chamber The test cannot be independently controlled and other problems, so as to avoid the interference of external adverse factors, improve the detection accuracy, and achieve the effect of comprehensive control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

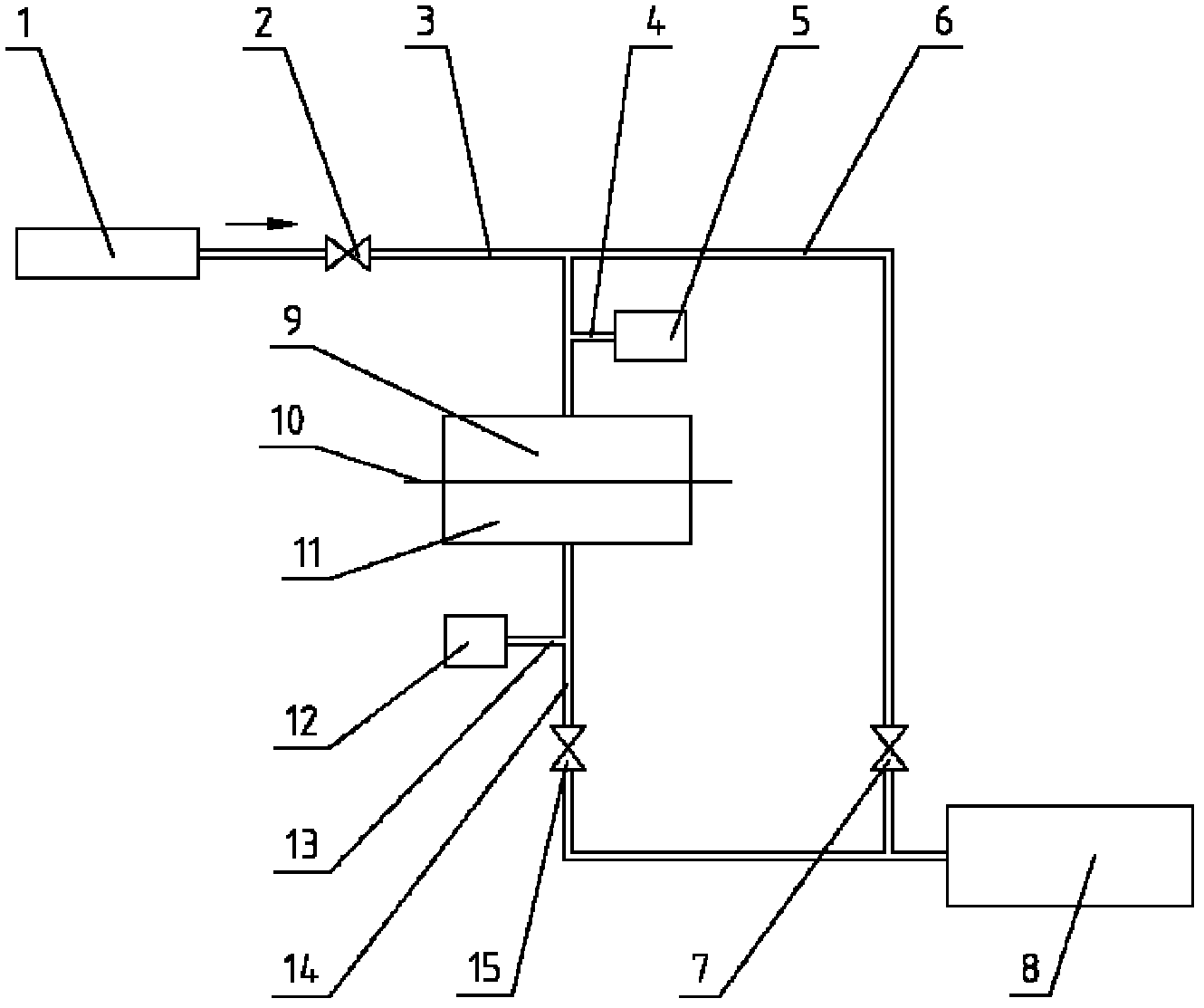

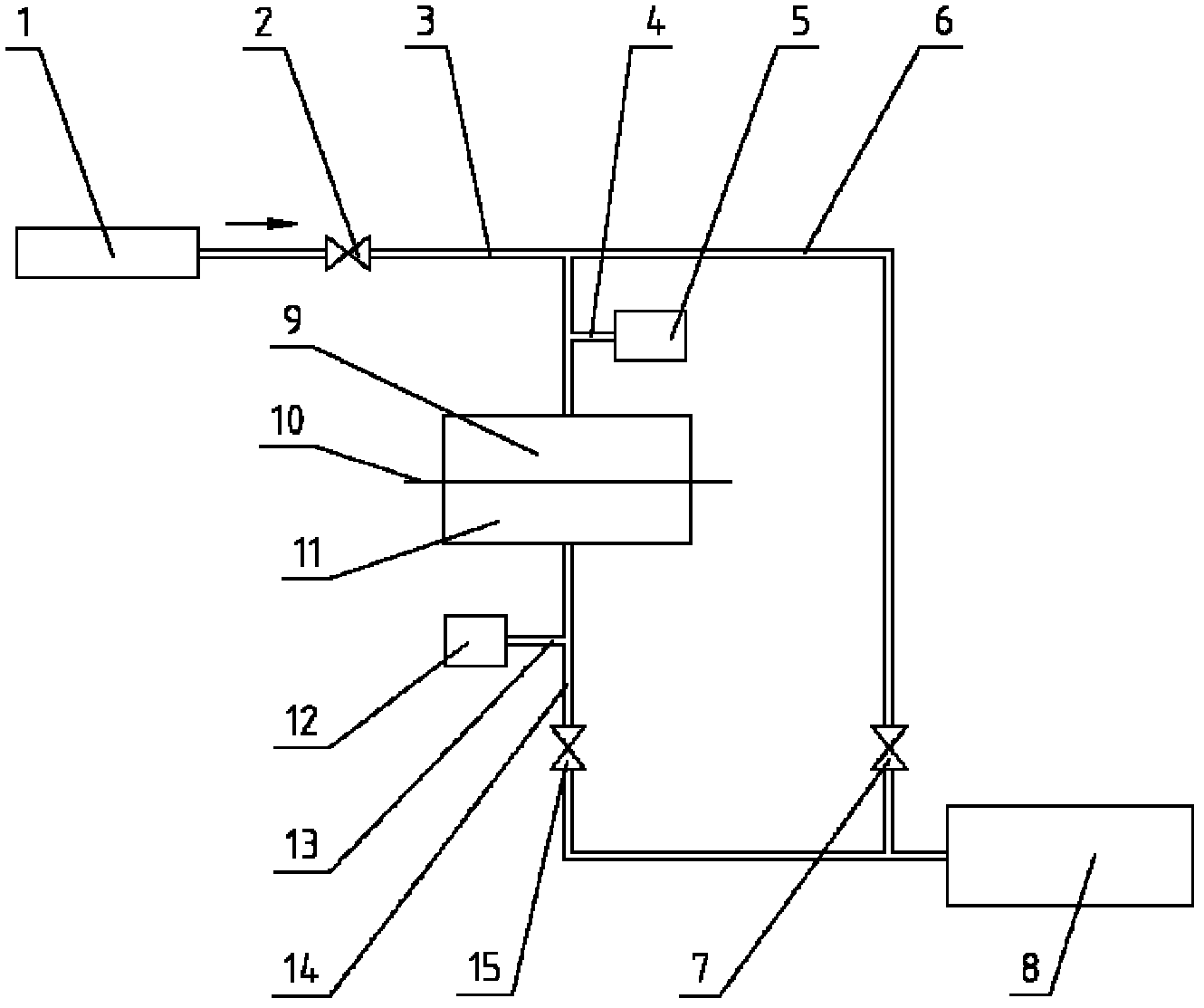

Embodiment 1

[0027] A gas permeability testing device, combined with figure 1 , including permeation tank, connecting pipeline, vacuum pump 8, pressure sensor, valve, and gas source six parts. The permeation cell is divided into two parts by the sample 10, the test chamber 11 and the test gas chamber 9; the test chamber 11 is connected with the pressure sensor I12, and connected with the vacuum pump 8 through the pipeline I14, and the pipeline I14 is provided with a valve I15; the test gas chamber 9 It is connected to the pressure sensor II5, and is connected to the vacuum pump 8 and the test gas source 1 respectively through the pipeline II6 and the pipeline III3. The pipeline II6 is provided with a valve II7, and the pipeline III3 is provided with a valve III2. The vacuum pump 8 is respectively connected to the test chamber 11 and the test gas chamber 9 through the pipeline I14 and the pipeline II6. By controlling the state of the valve I15 and the valve II7, the individual vacuuming of ...

Embodiment 2

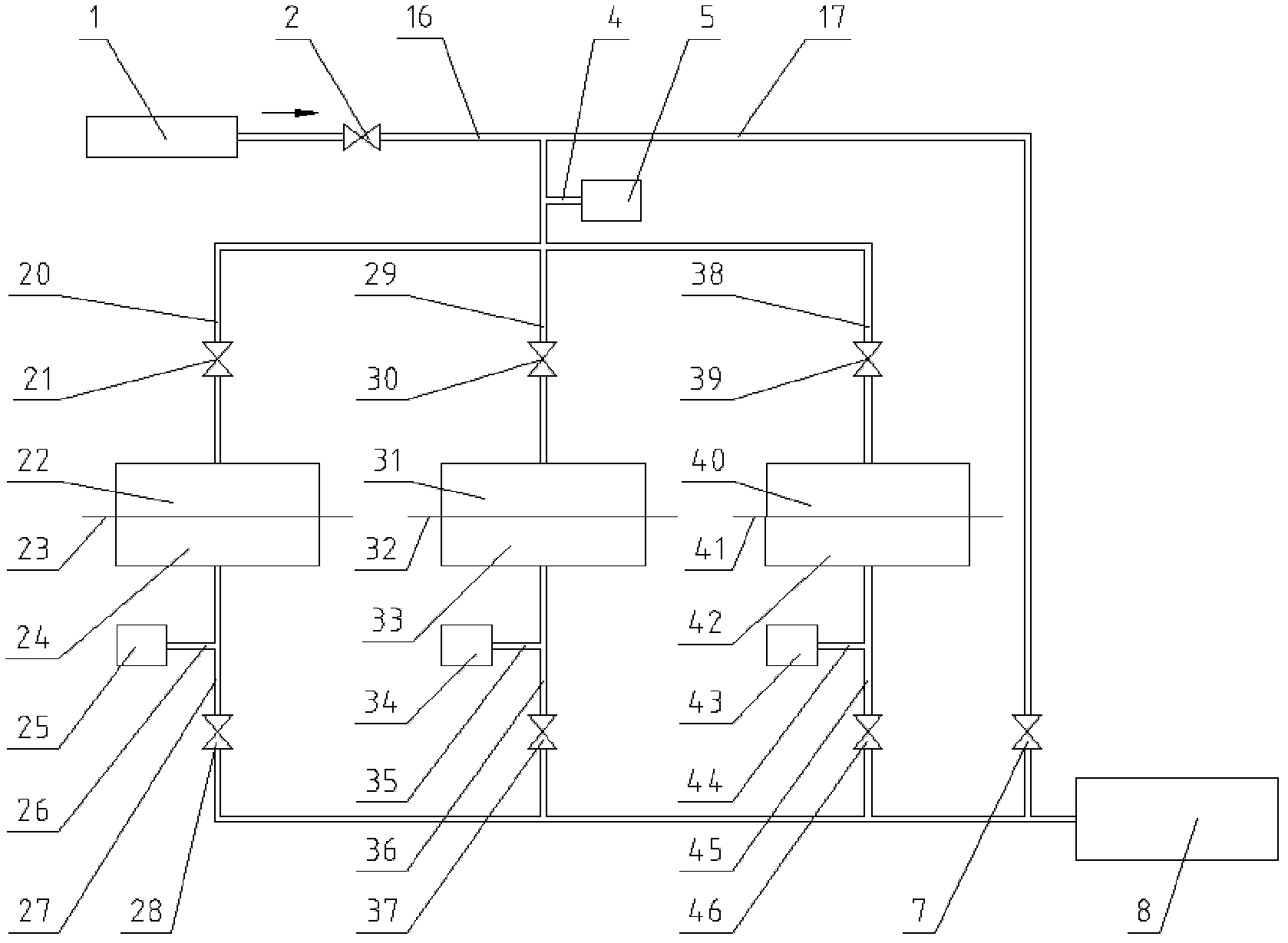

[0030] A gas permeability testing device, combined with figure 2 , is a three-chamber test structure of the present invention, that is, in the present invention, the number of permeation pools can be increased to increase test stations and realize independent control of multi-chamber tests. Including permeation tank, connecting pipeline, vacuum pump 8, pressure sensor, valve, and gas source six parts. Each permeation cell is divided into two parts by the sample, the test chamber and the test gas chamber. The 1# permeation cell is divided into two parts: the 1# test chamber 24 and the 1# test gas chamber 22 by the 1# sample 23. The 2# permeation cell is divided into two parts by 2 #Sample 32 is divided into 2# test chamber 33 and 2# test gas chamber 31, and 3# permeation cell is divided into 3# test chamber 42 and 3# test gas chamber 40 by 3# sample 41. Each test chamber is connected to the corresponding pressure sensor 1, and is connected to the vacuum pump 8 through the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com