Highly attachable high-conductivity photovoltaic welding strip

A photovoltaic ribbon, high conductivity technology, applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of poor electrical conductivity of the ribbon, poor tin electrical conductivity, etc., to achieve the effect of ensuring the conduction of electricity and ensuring the electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

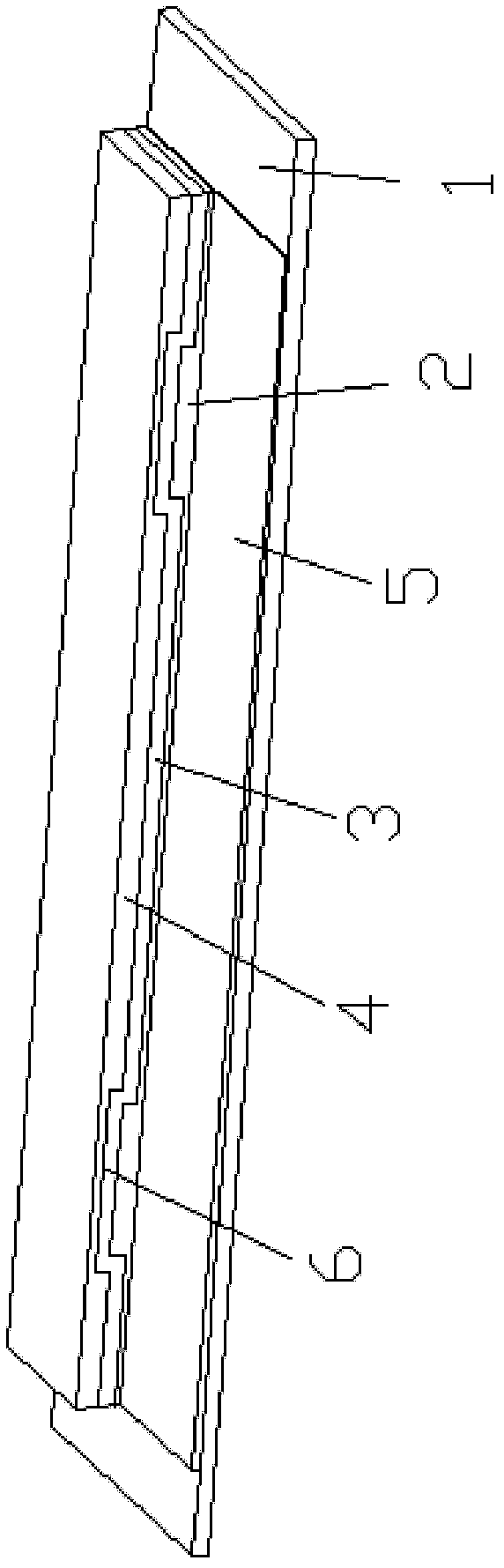

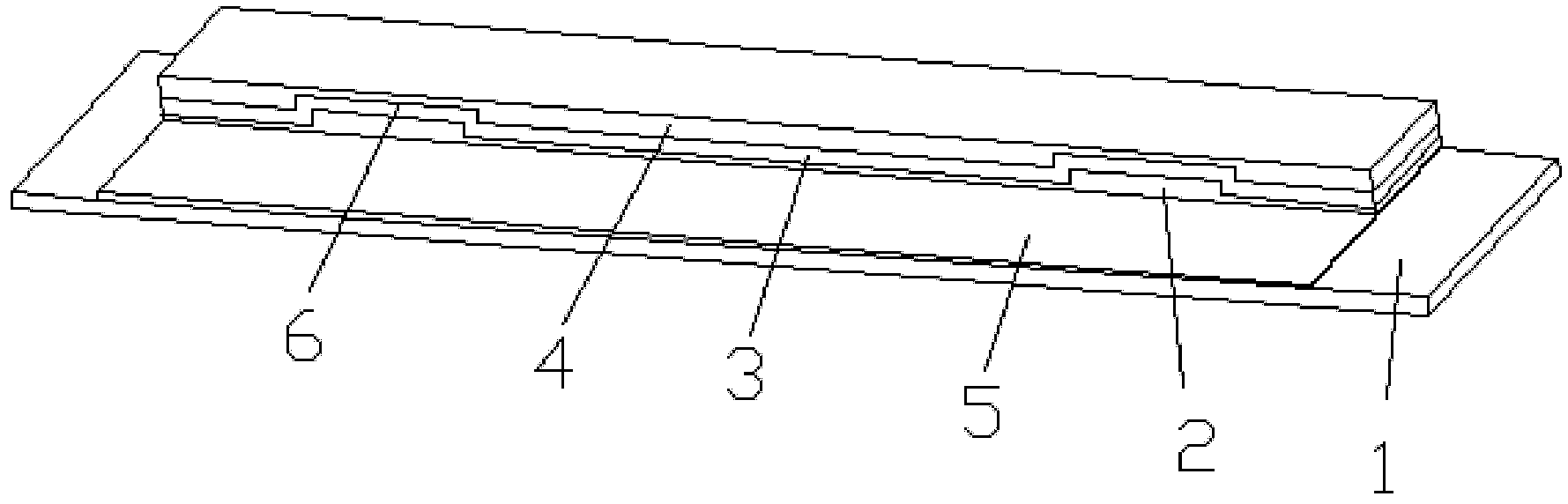

[0013] A high-adherence and high-conductivity photovoltaic soldering tape, including a battery sheet 1, a lower tin layer 2, a copper base tape 3 and an upper tin layer 4, and the upper tin layer, copper base tape and lower tin layer are attached to the Located on the upper side of the silver paste layer 5 on the upper side of the battery sheet, it is characterized in that two convex grooves 6 facing the upper tin layer are symmetrically formed on the copper base strip. In this way, the copper base strip can be closer to the battery sheet at the position where there is no convex groove, thereby improving the conductivity of the solder strip. the connection strength between them.

[0014] Preferably, the cross section of the convex groove is rectangular.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com