Device for on-line adaptation of motor for automatic operation at optimum efficiency

An optimal efficiency, automatic operation technology, applied in the direction of AC motor control, electrical components, power factor control, etc., can solve problems such as energy waste and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

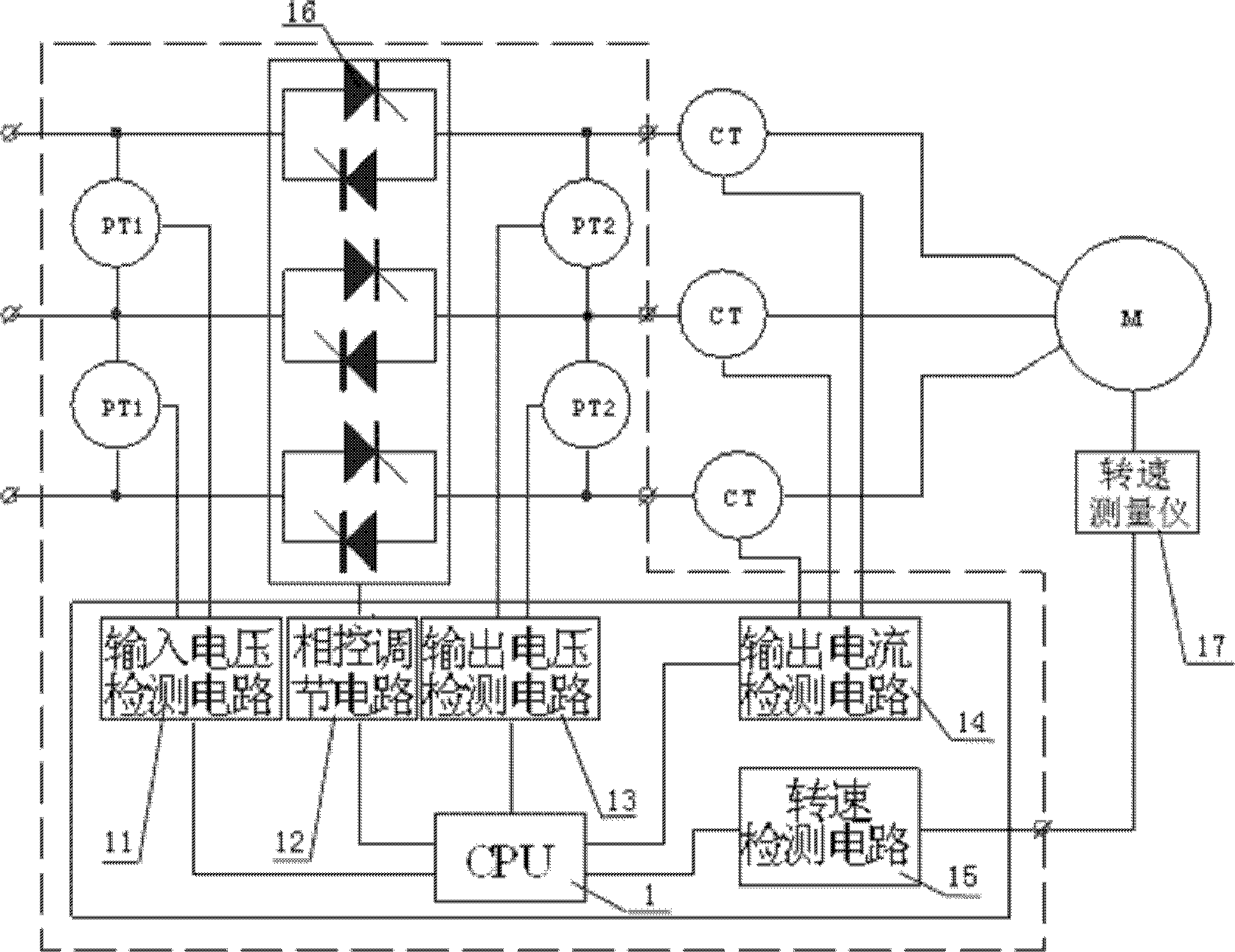

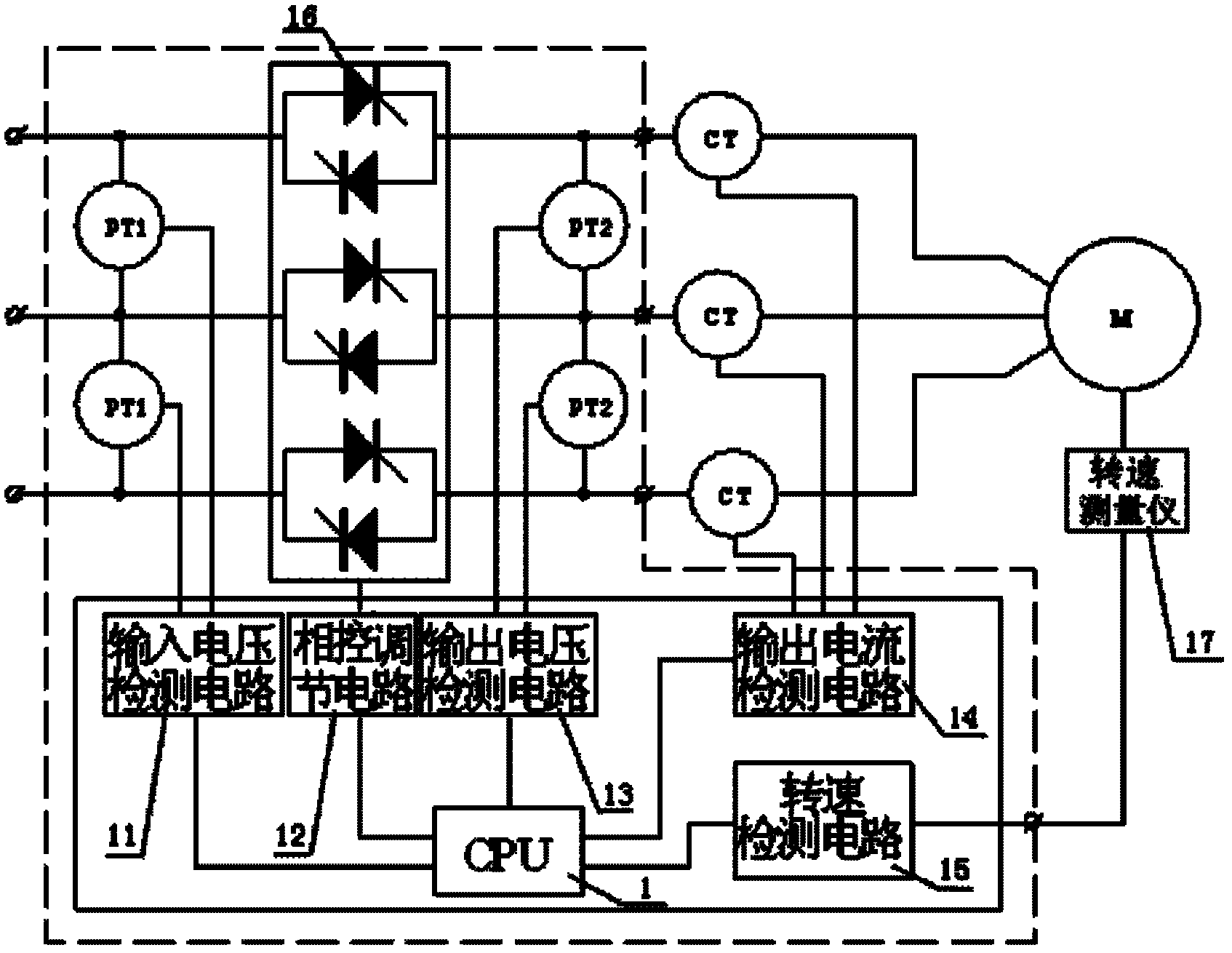

[0012] Combine below figure 1 The present invention is described in further detail:

[0013] The three-phase power supply of the present invention first passes through two input voltage transformers PT1 for measuring three-phase line voltages, two thyristors 16 connected in reverse parallel on each phase line, two output voltage transformers PT2 for measuring three-phase line voltages, and is connected in sequence. The current transformer CT on each phase line is then connected to the motor M, so that the device is connected in series between the three-phase power supply and the motor. Before the device is put into use, each parameter on the nameplate of the motor should be preset inside the device, and each time a different motor is replaced in the future, the corresponding parameters should be preset again; the motor parameters generally include rated voltage, rated current, rated speed Number, rated power, rated power factor, no-load current, etc. Presetting these paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com