Vacuum freeze drying method for flying fish roe

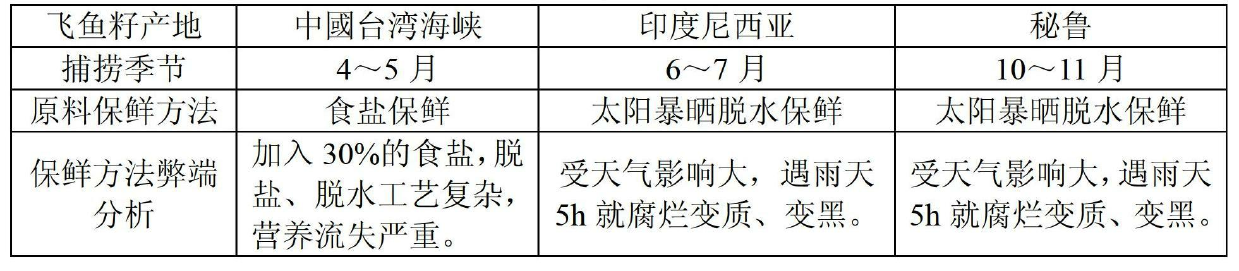

A technology of vacuum freeze-drying and flying fish roe, which is applied in meat/fish preservation, food preservation, food science, etc. It can solve the problems of complex desalination process, uncontrollable salinity, and loss of nutrients, so as to achieve high value and retain nutrients Composition, the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The present invention adopts the vacuum freeze-drying method to dehydrate the fresh flying fish roe caught into dry flying fish roe, and its technological process is as follows:

[0020] The freshly caught flying fish roe is cleaned of weeds, plastics and other polluting wastes, immediately washed with sea water and drained, and then put into the freezing room for ultra-low temperature (-40~-42°C) rapid freezing. The conditions for rapid freezing The method is: make the center temperature of the flying fish roe reach -18°C within 3 hours, and then leave the warehouse, enter the vacuum freeze-drying box and use the radiation type cold and heat exchange method for dehydration. The heat exchange temperature does not exceed 60°C, and the exchange temperature of the cold source is not low. At -30°C, the dehydration rate of the product reaches 75%, and the dried flying fish roe is obtained. After the dried fish roe is rehydrated and swelled, it is prepared with condiments and...

Embodiment 2

[0022] Similar to Example 1, the difference lies in the rapid freezing temperature of -42°C to -45°C, and the rapid freezing condition is: the central temperature of the flying fish roe reaches -20°C within 2.5 hours before being released from the warehouse.

Embodiment 3

[0024] Similar to Example 1, the difference lies in the rapid freezing temperature of -45 to -47°C, and the rapid freezing condition is: the central temperature of the flying fish roe reaches -22°C within 2.5 hours before being released from the warehouse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com