Automatic regeneration device of suppression column used in low-pressure ion chromatography

A low-pressure ion chromatography and automatic regeneration technology, applied in the field of low-pressure ion chromatography, can solve the problems of wasting manpower, difficult to accurately control regeneration liquid and cleaning liquid, etc., and achieve the effects of simple structure, labor saving, and accurate injection volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

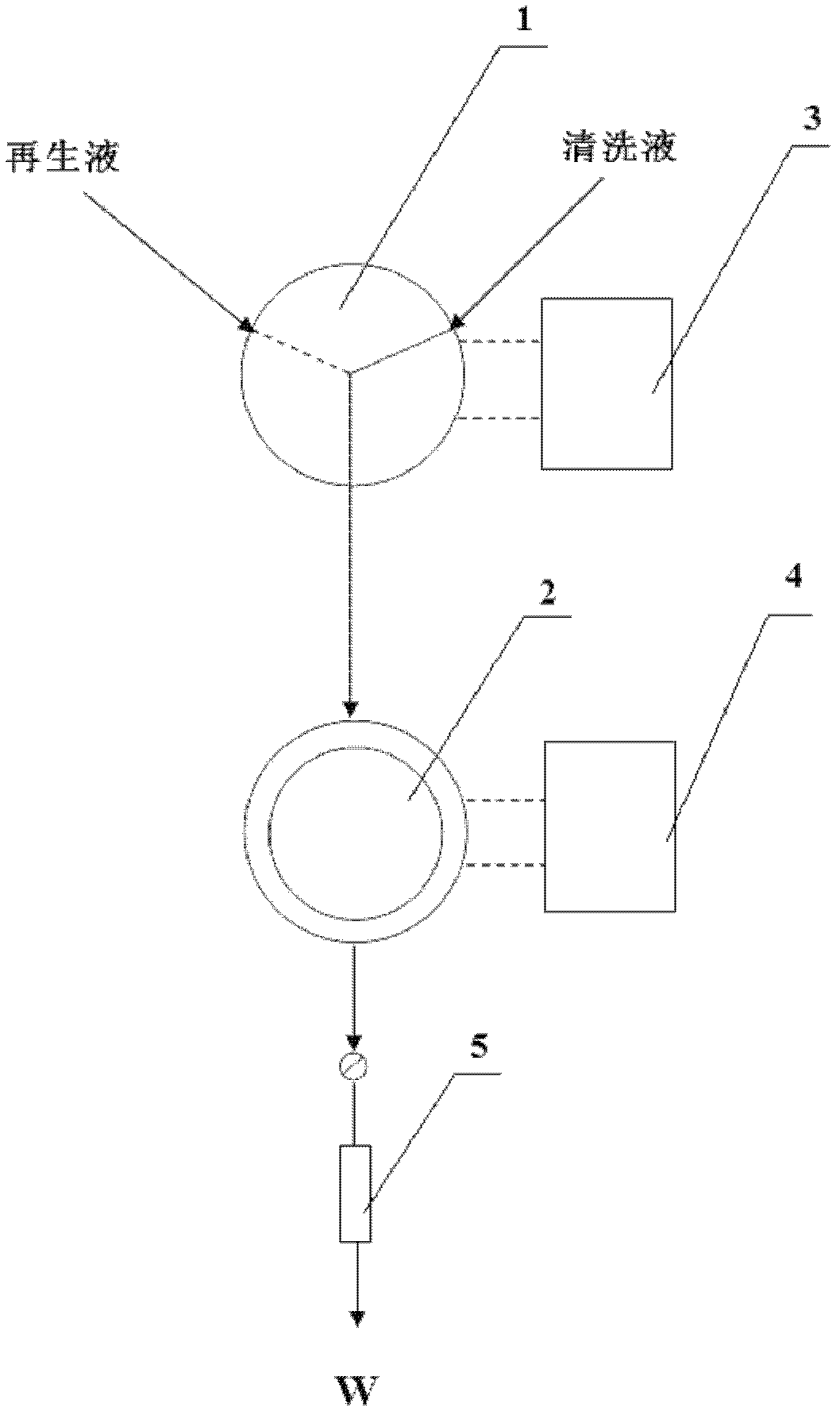

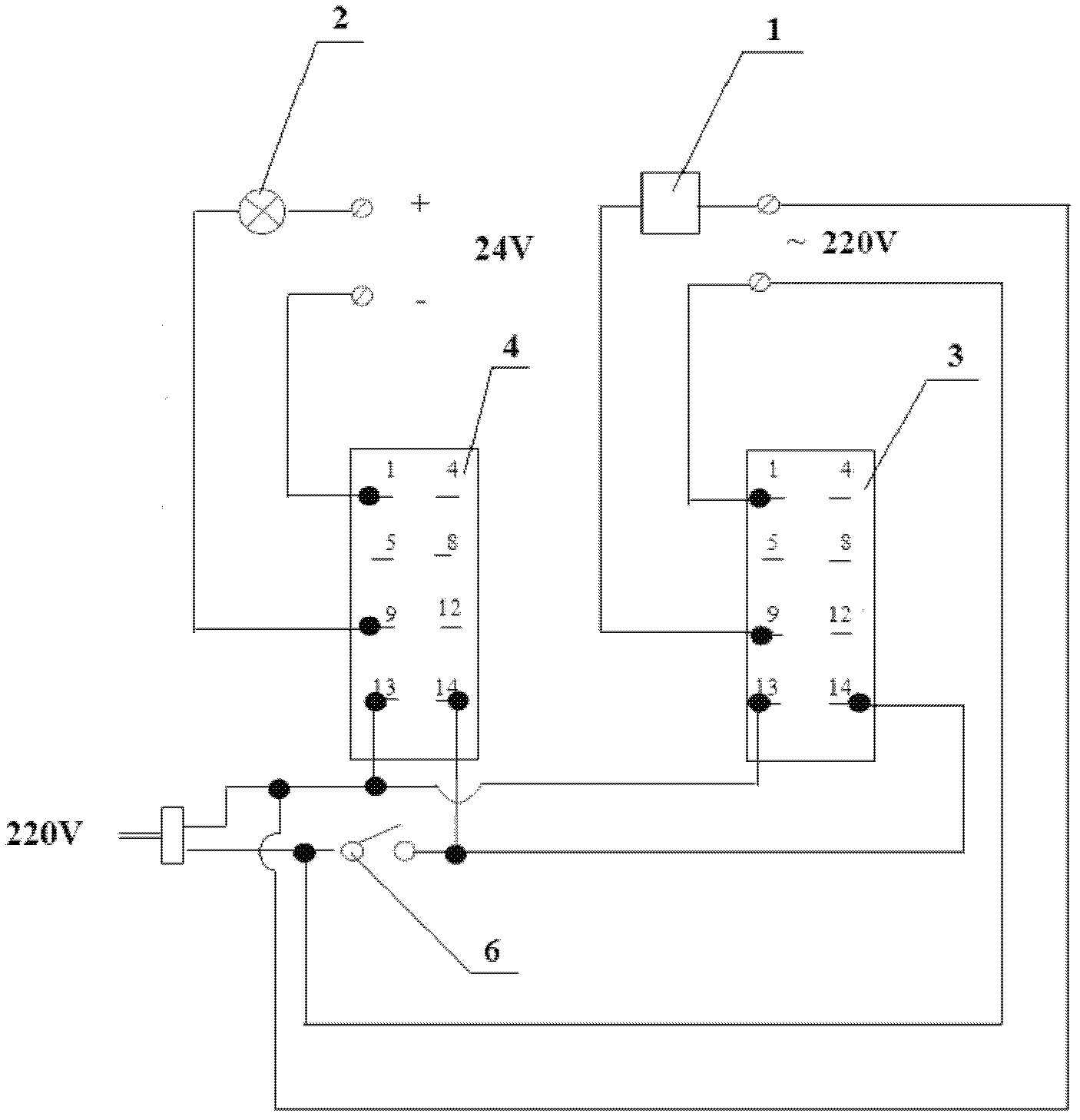

[0024] In this embodiment, the automatic regeneration device of the suppression column used in the low-pressure ion chromatography analysis is as follows: figure 1 , figure 2 , image 3 as shown,

[0025] It includes a liquid injector, a first time relay 3 and a second time relay 4; the liquid injector is composed of a three-way solenoid valve 1 and a low-pressure pump 2 connected to the three-way solenoid valve through pipe fittings, and the three-way solenoid valve 1 is anti-corrosion Solenoid valve (model: ZCF3-1, manufacturer: Xi'an Huiyuan Instrument Valve Co., Ltd.), low-pressure pump 2 is a low-pressure peristaltic pump (model: 102K miniature peristaltic pump, manufacturer: Chongqing Jieheng Peristaltic Pump Co., Ltd.), flow rate 2ml / min, working pressure 2.5×10 5 Pa; the first time relay 3 and the second time relay 4 are automatic control time relays (model: ZYS48-S, manufacturer: Shanghai Zhuoyi Electronics Co., Ltd.); the first time relay 3 and the three-way sol...

Embodiment 2

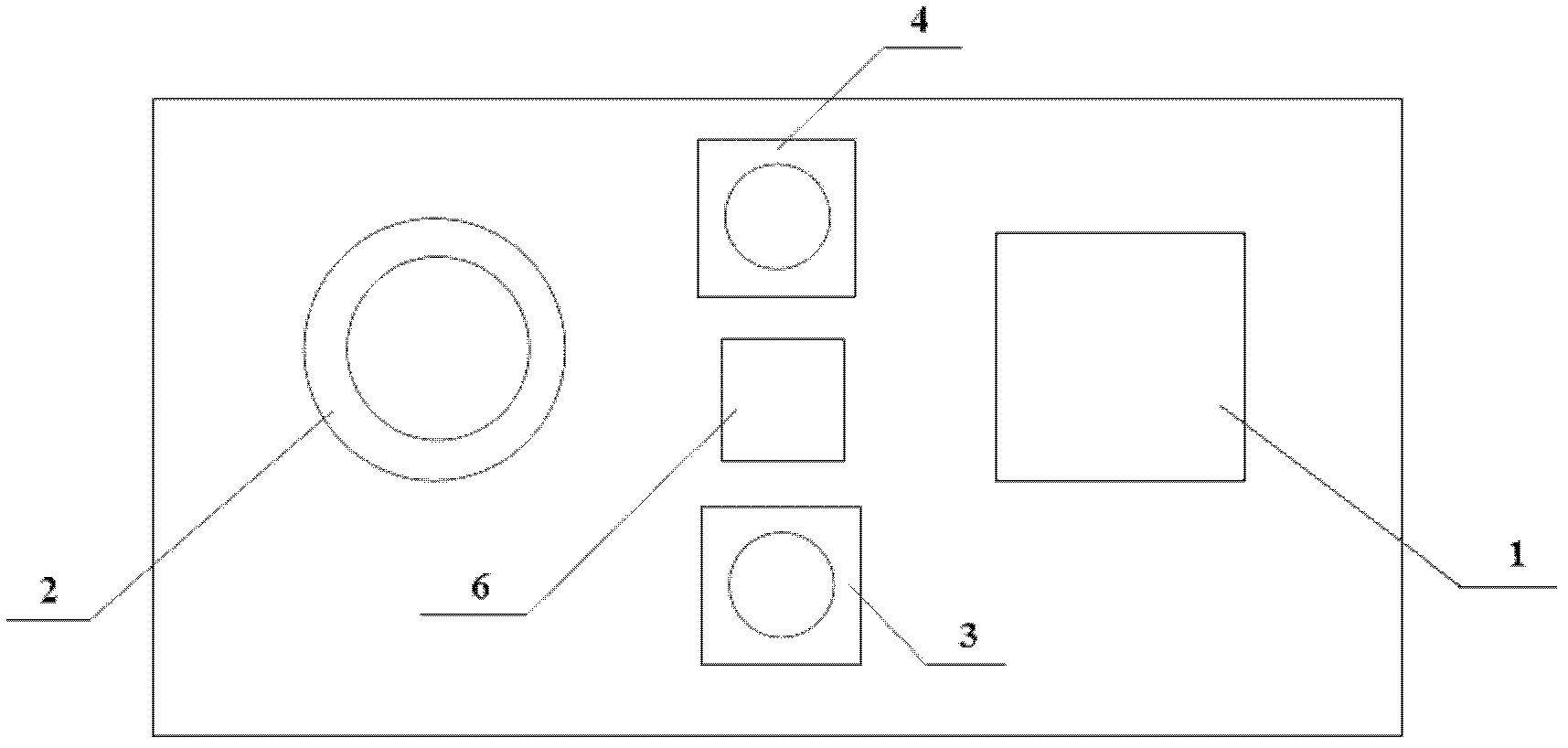

[0033] In this embodiment, the automatic regeneration device of the suppression column used in the low-pressure ion chromatography analysis is as follows: Figure 4 , Figure 5 , Figure 6 As shown, it includes a liquid injector, a first time relay 3 and a second time relay 4; the liquid injector is composed of a regeneration liquid injection pump 7 and a cleaning liquid injection pump 8, and the regeneration liquid injection pump 7 and the cleaning liquid injection pump 8 All are low-pressure peristaltic pumps (model: 102K miniature peristaltic pump, manufacturer: Chongqing Jieheng Peristaltic Pump Co., Ltd.), their flow rate is 1.5ml / min, and their working pressure is 2.5×10 5 Pa; the first time relay 3 and the second time relay 4 are automatic control time relays (model: ZYS48-S, manufacturer: Shanghai Zhuoyi Electronics Co., Ltd.); the first time relay 3 and the regeneration liquid injection pump 7 The motor is connected to control the regeneration liquid injection pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com