Automatic ion exchange resin regeneration system and method

An ion exchange resin, automatic regeneration technology, applied in the direction of electric regeneration, etc., can solve the problems of low regeneration degree, ion exchange resin failure, ion exchange resin consumption is not large, etc., to achieve the effect of simple operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

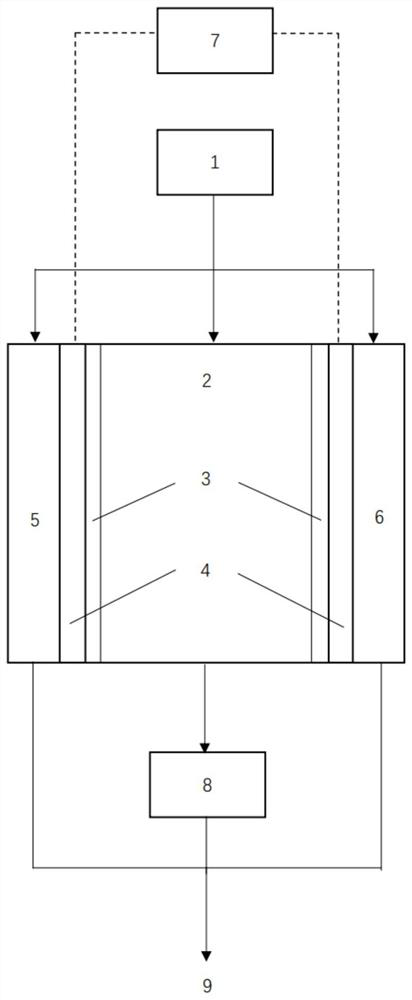

[0027] see figure 1 , this embodiment provides an ion exchange resin automatic regeneration system, including a reaction shell, an ion exchange membrane 3 and a pure water tank 1; there are two ion exchange membranes 3, and the two ion exchange membranes 3 are parallel and vertically placed in the reaction shell On the bottom surface, the side walls of the two ion exchange membranes 3 are in contact with the inner wall of the reaction shell, and the reaction shell is divided into a positive electrolysis chamber 5, a regeneration reaction chamber 2 and a negative electrolysis chamber 6 in turn; the pure water tank 1 is placed in the reaction chamber. The outside of the shell is communicated with the positive electrolysis chamber 5 , the regeneration reaction chamber 2 and the negative electrolysis chamber 6 respectively.

[0028] Specifically, the reaction shell is a sealed rectangular container, two ion exchange membranes 3 are placed vertically on the inner bottom surface of ...

Embodiment 2

[0041] Different from Embodiment 1, in this embodiment, the ion-exchange membrane 3 is a cation-exchange membrane, and specifically, a membrane sheet commonly used in EDI equipment is selected. The ion exchange resin to be regenerated is a cation exchange resin.

[0042] The ion exchange resin automatic regeneration system provided by this embodiment, its regeneration method comprises the following steps:

[0043] 1) the ion exchange resin to be regenerated is placed in the regeneration reaction chamber 2, and pure water is passed into the regeneration reaction chamber 2, the positive electrolysis chamber 5 and the anion electrolysis chamber 6 respectively;

[0044] 2) switch on the power supply 7, the electrolytic electrode plate 4 in the positive electrolysis chamber 5 and the electrolytic electrode plate 4 in the negative electrolysis chamber 6 all produce electrode reactions; the hydrogen ions generated by pure water electrolysis in the positive electrolysis chamber 5 pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity value | aaaaa | aaaaa |

| Conductivity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com