Integrated disassembling and welding machine of diamond saw blade

A diamond saw blade and integrated machine technology, applied in metal sawing equipment, metal processing, welding equipment and other directions, can solve the problem of not being able to complete the cutting head required for welding at one time, affecting the malfunction of the photoelectric sensor, and placing the cutting head. Limited space and other problems, to achieve the effect of stable conveying and feeding quality, ample placement time and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

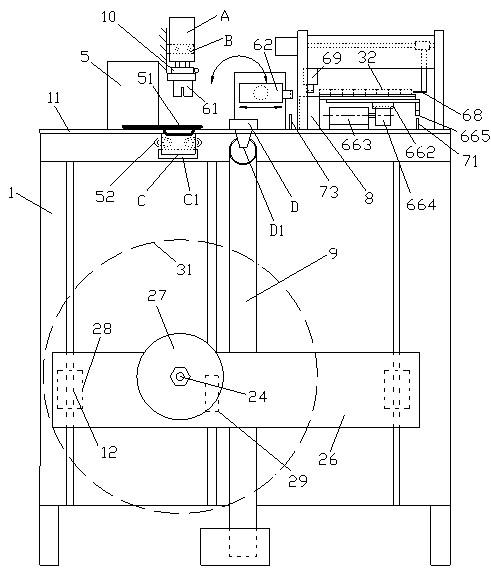

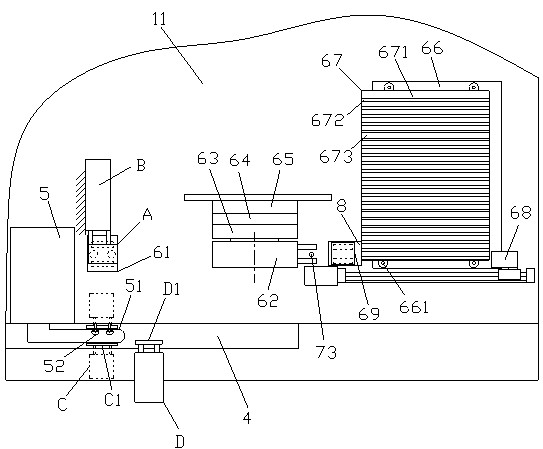

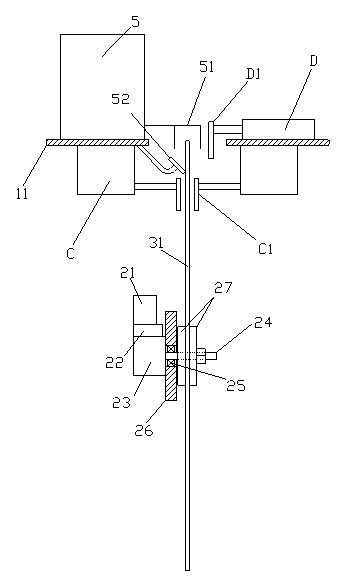

[0021] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail together with the accompanying drawings.

[0022] Referring to the legend, a diamond saw blade desoldering integrated machine, including a machine table 1 and a working table 11 above the machine table 1, is characterized in that a liftable saw blade clamp 2 is provided on the side wall of the machine table 1 The edge of the work surface 11 which is located on one side of the saw blade clamp 2 and extends out of the machine platform 1 is provided with a port 4 for allowing the saw blade 31 to pass through; the high frequency heating device 5 is installed on the work surface 11, and the high frequency The annular heating coil 51 of the heating device 5 is located directly above the port 4 so as to facilitate the saw teeth of the saw blade 31 to extend into the annular heating coil 51, and the worktable 11 nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com