Cam preparation method and cam type four-cylinder single-action reciprocating pump

A cam and cam two technology, applied in the direction of pumps, piston pumps, mechanical equipment, etc., can solve the problems of difficulty in ensuring the synchronization of the three cams, increasing the difficulty of mass production of the cams, accelerating the fatigue damage of the cams, etc., and achieving torque reduction , Improve self-priming performance, eliminate the effect of flow and pressure pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

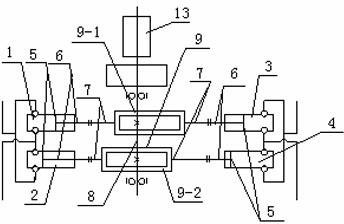

[0037] The present invention is described in detail below:

[0038] The prepared cam on the four-cylinder single-acting reciprocating pump used for drilling engineering, its preparation steps:

[0039] A kind of preparation method of cam, its steps:

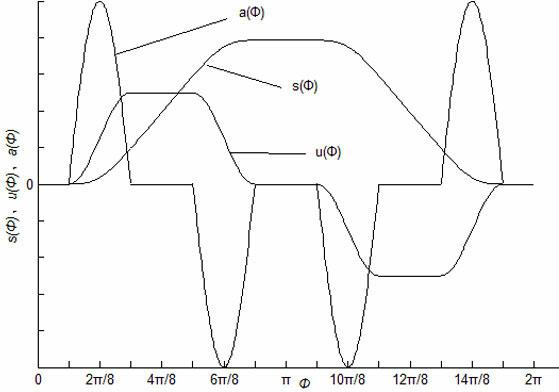

[0040] 1) Determine the upper contour line of the cam, the steps are:

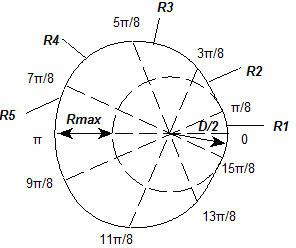

[0041] (1) Determine the contour radius R1 corresponding to the cam between 0 and π / 8 of the cam rotation, and the distance is a constant: 78.54mm;

[0042] (2) Determine the contour radius R2 corresponding to the cam between π / 8 and 3π / 8 of cam rotation:

[0043] Substitute ф=π / 8~3π / 8 into the following formula for calculation: =78.54~98.17 mm;

[0044] (3) Determine the contour radius R3 corresponding to the cam between 3π / 8~5π / 8 of the cam rotation,

[0045] Substitute ф=3π / 8~5π / 8 into the following formula for calculation: =98.17 ~137.44mm;

[0046] (4) Determine the contour radius R4 corresponding to the cam between 5π / 8~7π / 8 of the cam rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com