A self-loading and unloading hoisting mechanism mounted on a semi-trailer

A semi-trailer, self-loading and unloading technology, applied to vehicles with cranes and other directions, can solve the problems of inability to load and unload, poor practicability, etc., and achieve the effects of low manufacturing cost, simple structure, and improved transportation loading and unloading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

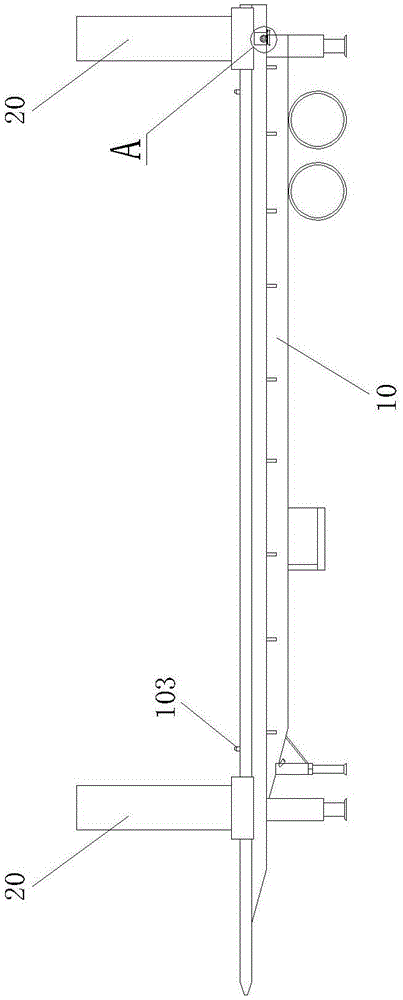

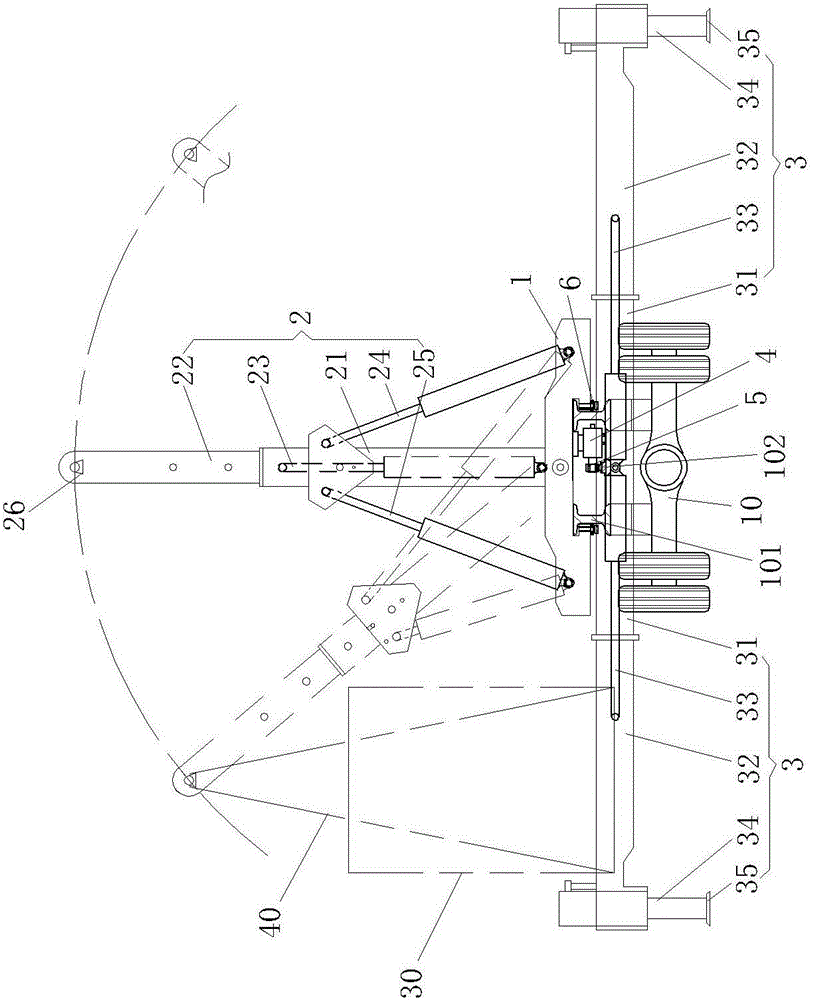

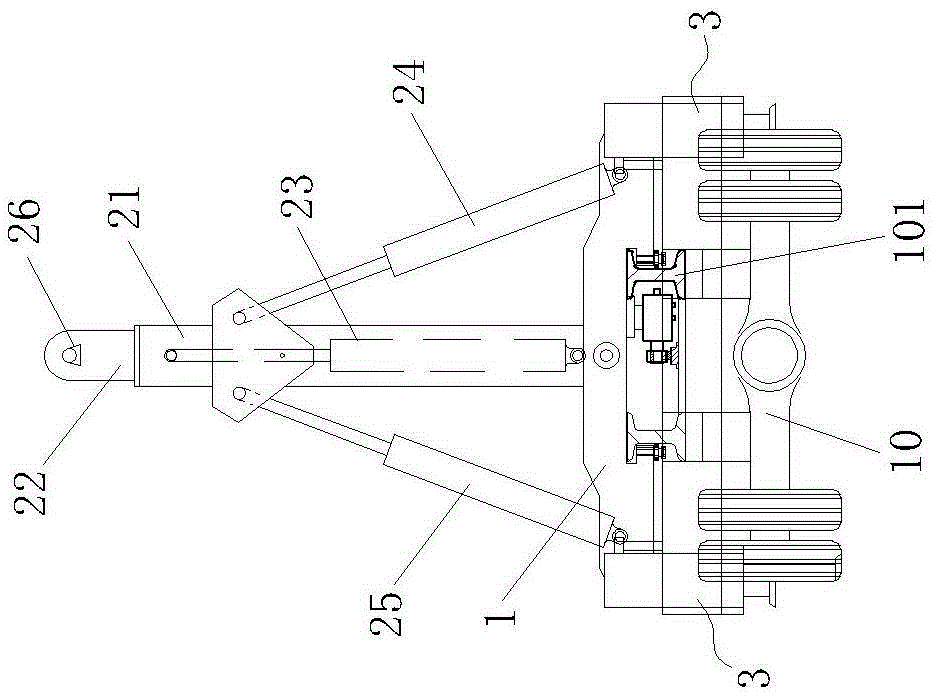

[0020] Embodiment one: Figure 1 to Figure 4 As shown, a self-loading and unloading hoisting mechanism mounted on a semi-trailer includes a semi-trailer chassis 10, and a hoisting mechanism 20 is respectively installed at both ends of the semi-trailer chassis 10. The hoisting mechanism 20 includes: a base 1, a lower part of the base 1 clamped on the beam 101 of the semi-trailer chassis 10;

[0021] A telescopic crane assembly 2 is arranged in the middle of the upper part of the base 1. The telescopic crane assembly 2 includes a swing arm 21, a telescopic arm 22, and a telescopic arm cylinder 23. The telescopic arm 22 is sleeved on the swing arm 21, and the telescopic boom cylinder 23 The tail is hinged on the inner bottom of the swing arm 21, the piston rod of the telescopic arm cylinder 23 is hinged on the telescopic arm 22, the bottom of the swing arm 21 is hinged to the base 1, and the middle and upper sides of the swing arm 21 are connected to the base by swing cylinders 2...

Embodiment 2

[0025] Embodiment two, Figure 5 to Figure 7 As shown, it is different from Embodiment 1 in that a gantry-type support arm assembly 3 is not installed on both sides of the front and rear ends of the semi-trailer chassis 10, but instead a support arm assembly is installed on both sides of the top of the base 1, and the two support arms One of the components is a bridge leg type support arm assembly 7, and the other is a telescopic support arm assembly 8;

[0026] The bridge leg type support arm assembly 7 includes an inner arm 71, an inner arm oil cylinder 72, a support leg 73, and a support leg oil cylinder 74. The lower end of the inner arm 71 is hinged on one side of the base 1, and the cylinder tail of the inner arm oil cylinder 72 is hinged on the base 1, the front end of the inner arm oil cylinder 72 piston rod is hinged to the middle of the inner arm 71, the rear end of the support leg 73 is hinged to the front end of the inner arm 71, and the tail of the support leg oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com