Method for treating total nitrogen of nitrogen-containing chemical wastewater

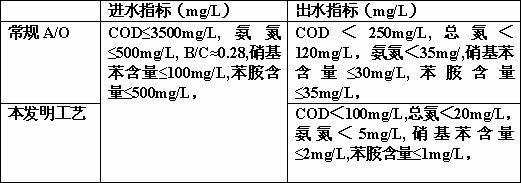

A treatment method and technology for chemical wastewater, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as instability of effluent ammonia nitrogen and ineffective control of effluent total nitrogen, etc. Achieve the effects of low processing cost, reduced operating cost, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

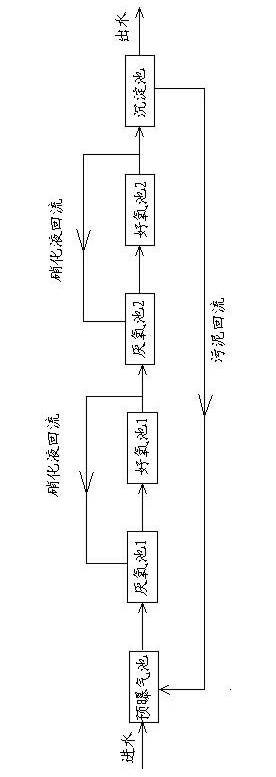

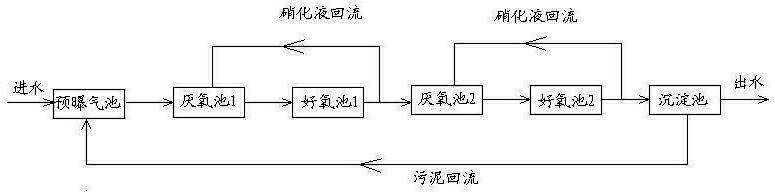

[0034] Embodiment 1, with reference to figure 1 , a treatment method suitable for total nitrogen in nitrogen-containing chemical wastewater, the method includes pre-aeration tank treatment and two-stage A / O treatment process;

[0035] There is an aeration device in the pre-aeration tank, through which part of COD and a large amount of organic matter are removed; the residence time of nitrogen-containing chemical wastewater in the pre-aeration tank is 6h, the temperature is 5°C; pH: 6, DO: 1mg / L, effective MLSS: 3500mg / L;

[0036] The wastewater treated in the pre-aeration tank enters the first-level A / O treatment process. The first-level A / O treatment process consists of a first-level aerobic tank and a first-level anaerobic tank. The first-level aerobic tank is used for the degradation of organic matter and ammonia nitrogen. Nitrification, denitrification in the first-level anaerobic tank, by adding an appropriate amount of glucose or other carbon sources to the first-level...

Embodiment 2

[0040] Embodiment 2, with reference to figure 1 , a treatment method suitable for total nitrogen in nitrogen-containing chemical wastewater, the method includes pre-aeration tank treatment and two-stage A / O treatment process;

[0041] There is an aeration device in the pre-aeration tank, which removes part of COD and a large amount of organic matter; the residence time of nitrogen-containing chemical wastewater in the pre-aeration tank is 24h, temperature: 40°C; pH: 10, DO: 5mg / L, effective MLSS: 6500mg / L;

[0042] The wastewater treated in the pre-aeration tank enters the first-level A / O treatment process. The first-level A / O treatment process consists of a first-level aerobic tank and a first-level anaerobic tank. The first-level aerobic tank is used for the degradation of organic matter and ammonia nitrogen. Nitrification, denitrification in the first-level anaerobic tank, by adding an appropriate amount of glucose or other carbon sources to the first-level anaerobic tank...

Embodiment 3

[0046] Embodiment 3, with reference to figure 1 , a treatment method suitable for total nitrogen in nitrogen-containing chemical wastewater, the method includes pre-aeration tank treatment and two-stage A / O treatment process;

[0047] There is an aeration device in the pre-aeration tank, through which part of COD and a large amount of organic matter are removed; the residence time of nitrogen-containing chemical wastewater in the pre-aeration tank is 12h, the temperature is 25°C; pH: 8, DO: 3mg / L, effective MLSS: 5000mg / L;

[0048] The wastewater treated in the pre-aeration tank enters the first-level A / O treatment process. The first-level A / O treatment process consists of a first-level aerobic tank and a first-level anaerobic tank. The first-level aerobic tank is used for the degradation of organic matter and ammonia nitrogen. Nitrification, denitrification in the first-level anaerobic tank, by adding an appropriate amount of glucose or other carbon sources to the first-lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com