Ultra-coarse grain cemented carbide secondary liquid-phase sintering process

A cemented carbide, liquid phase sintering technology, applied in the secondary liquid phase sintering process of ultra-coarse-grained cemented carbide, can solve the problems of affecting the service life of alloy products, difficulty in product size control, product sintering deformation, etc. Effect of phase content and liquid phase diffusion time, reducing microporosity, and improving product performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

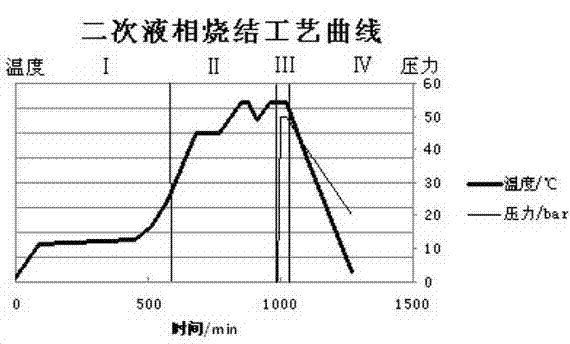

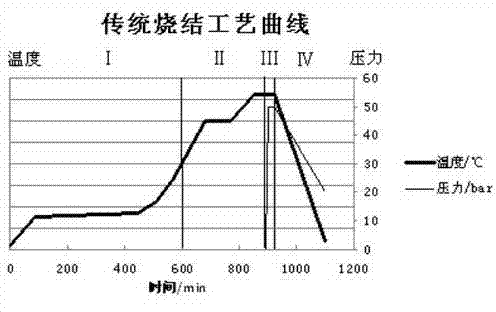

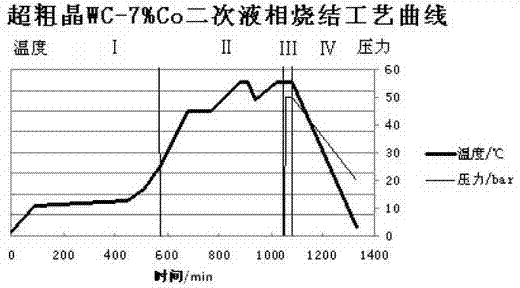

[0036] The composition of ultra-coarse-grained cemented carbide is WC-7% Co, and the sintering temperature is 1480°C. In the vacuum sintering stage, the temperature was raised to 1480°C, kept for 20 minutes, then lowered to 1300°C at a rate of 6°C / min, then raised to 1480°C at a rate of 3°C / min, kept for 20 minutes, and then turned to pressure sintering. Sintering curve as Figure 5 shown.

[0037] The properties of WC-7%Co products prepared by the secondary liquid phase sintering process are shown in Table 2. metallographic photo see Figure 6-1 and Figure 6-2 .

[0038] Table 2 Performance comparison of ultra-coarse grain WC-7%Co products prepared by two sintering processes

[0039] Sintering process

Embodiment 2

[0041] The ultra-coarse-grained cemented carbide composition is WC-10% Co, and the sintering temperature is 1450°C. In the vacuum sintering stage, the temperature was raised to 1450°C, kept for 20 minutes, then lowered to 1300°C at a rate of 6°C / min, then raised to 1450°C at a rate of 3°C / min, kept for 30 minutes, and then turned to pressure sintering. Sintering curve as Figure 7 shown.

[0042] The properties of WC-10%Co products prepared by the secondary liquid phase sintering process are shown in Table 3. metallographic photo see Figure 8-1 and Figure 8-2 .

[0043] Table 3 Performance comparison of ultra-coarse grain WC-10%Co products prepared by two sintering processes

[0044] Sintering process

Embodiment 3

[0046] The composition of ultra-coarse-grained cemented carbide is WC-17.5% Co, and the sintering temperature is 1390°C. In the vacuum sintering stage, the temperature was raised to 1390°C, kept for 20 minutes, then lowered to 1280°C at a rate of 6°C / min, then raised to 1390°C at a rate of 2°C / min, kept for 30 minutes, and then turned to pressure sintering. Sintering curve as Figure 9 shown.

[0047] The properties of WC-17.5% Co products prepared by the secondary liquid phase sintering process are shown in Table 4. metallographic photo see Figure 10 .

[0048] Table 4 Performance comparison of ultra-coarse grain WC-17.5%Co products prepared by two sintering processes

[0049] Sintering process

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com