Ni3Al intermetallic-based solid self-lubricating composite material and preparation method thereof

An intermetallic compound, solid self-lubricating technology, applied in the field of Ni3Al intermetallic compound-based solid self-lubricating composite material and its preparation, can solve the problem of the wettability of lubricant and matrix, the difficulty in controlling interface reaction and interface structure, and the improvement of lubricating performance. The effect is not obvious, the stability of the lubricant is difficult to guarantee, etc., to achieve the effect of excellent tribological properties, shortened sintering time, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

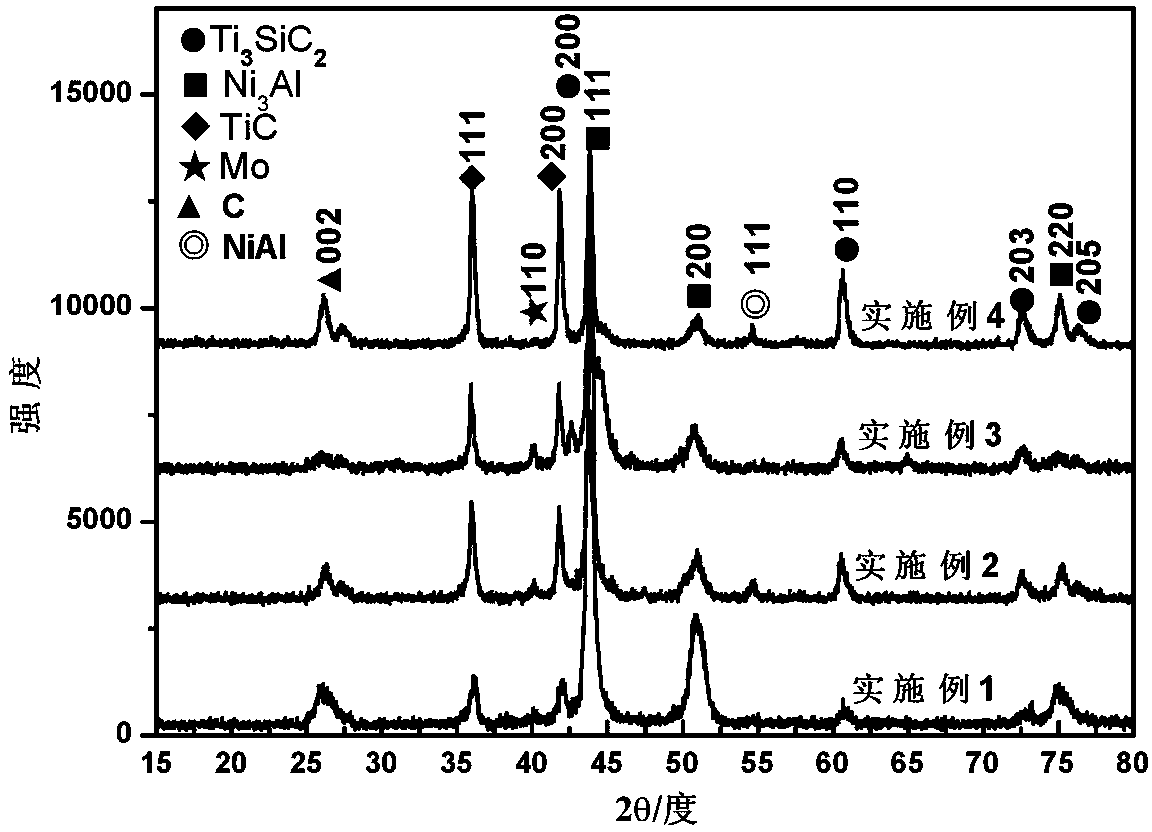

[0050] Ni 3 Al intermetallic compound-based solid self-lubricating composite material is characterized in that it consists of Ni powder, Al powder, Cr powder, Mo powder, Zr powder, B powder and Ti 3 SiC 2 Powder prepared, where the molar ratio of Ni:Al:Cr:Mo:Zr:B=4.5:1:0.333:0.243:0.0047:0.0015, Ti 3 SiC 2 The amount of powder added is 5% of the total mass of Ni powder, Al powder, Cr powder, Mo powder, Zr powder and B powder.

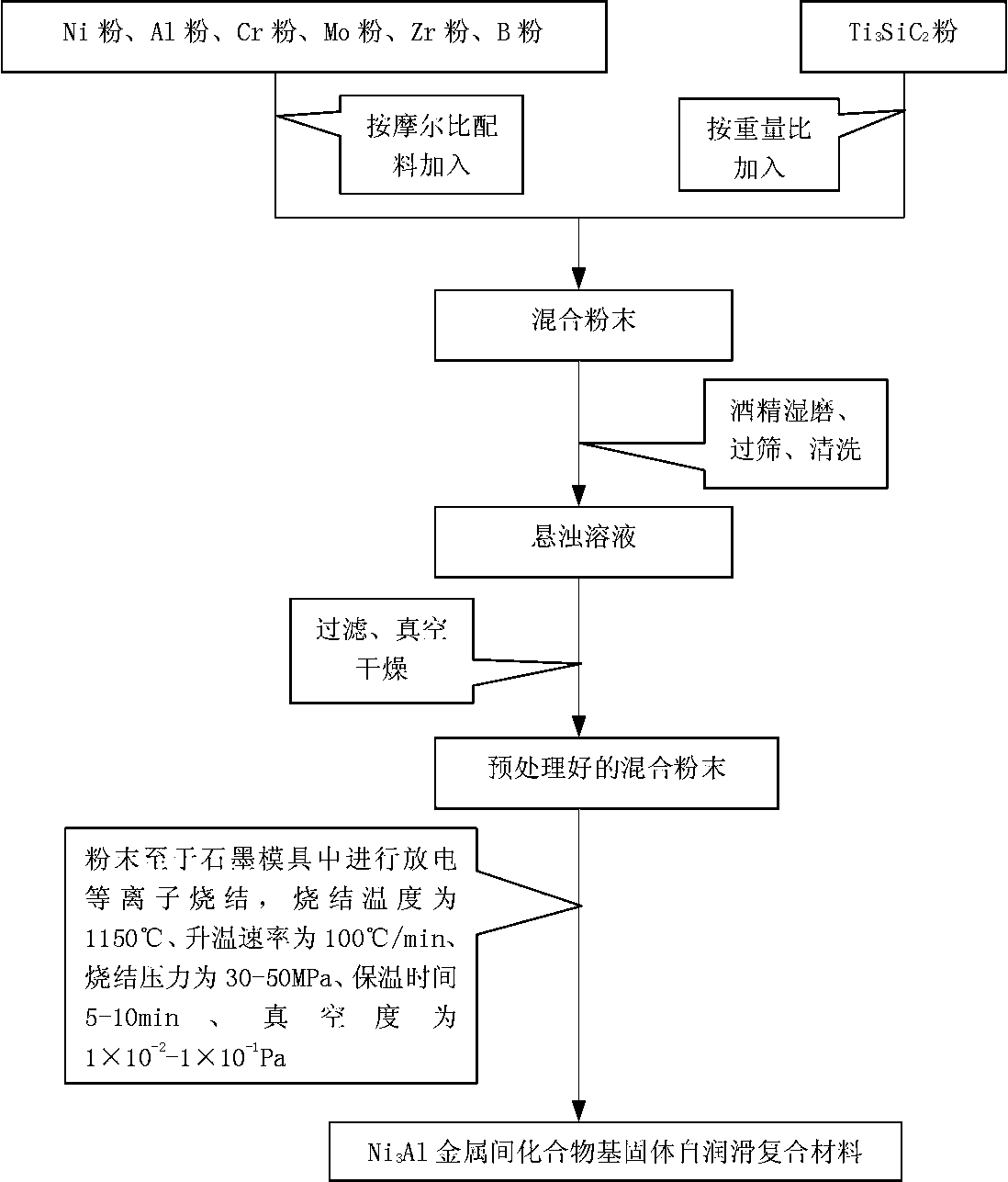

[0051] The above Ni 3 The preparation method of Al intermetallic compound base solid self-lubricating composite material, it comprises the steps:

[0052] 1) Using Ni powder, Al powder, Cr powder, Mo powder, Zr powder and B powder as the base material, Ti 3 SiC 2 The powder (powder material) is the lubricant reinforcement phase. According to the molar ratio of Ni:Al:Cr:Mo:Zr:B=4.5:1:0.333:0.243:0.0047:0.0015, weigh 7.952 grams of Ni powder and 0.81 grams of Al powder , 0.523 grams of Cr powder, 0.702 grams of Mo powder, 0.013 grams of Zr powder a...

Embodiment 2

[0058] Ni 3 Al intermetallic compound-based solid self-lubricating composite material is characterized in that it consists of Ni powder, Al powder, Cr powder, Mo powder, Zr powder, B powder and Ti 3 SiC 2 Powder prepared, where the molar ratio of Ni:Al:Cr:Mo:Zr:B=4.5:1:0.333:0.243:0.0047:0.0015, Ti 3 SiC 2 The amount of powder added is 10% of the total mass of Ni powder, Al powder, Cr powder, Mo powder, Zr powder and B powder.

[0059] The above Ni 3 The preparation method of Al intermetallic compound base solid self-lubricating composite material, it comprises the steps:

[0060] 1) Using Ni powder, Al powder, Cr powder, Mo powder, Zr powder and B powder as the matrix raw materials, Ti 3 SiC 2 The powder is the lubricant reinforcement phase, according to the molar ratio of Ni:Al:Cr:Mo:Zr:B=4.5:1:0.333:0.243:0.0047:0.0015, weigh 7.952 grams of Ni powder, 0.81 grams of Al powder, 0.523 grams of Cr powder, 0.702 grams of Mo powder, 0.013 grams of Zr powder and 0.0005 gram...

Embodiment 3

[0066] Ni 3 Al intermetallic compound-based solid self-lubricating composite material is characterized in that it consists of Ni powder, Al powder, Cr powder, Mo powder, Zr powder, B powder and Ti 3 SiC 2 Powder prepared, where the molar ratio of Ni:Al:Cr:Mo:Zr:B=4.5:1:0.333:0.243:0.0047:0.0015, Ti 3 SiC 2 The amount of powder added is 15% of the total mass of Ni powder, Al powder, Cr powder, Mo powder, Zr powder and B powder.

[0067] The above Ni 3 The preparation method of Al intermetallic compound base solid self-lubricating composite material, it comprises the steps:

[0068] 1) Using Ni powder, Al powder, Cr powder, Mo powder, Zr powder and B powder as the matrix raw materials, Ti 3 SiC 2 The powder is the lubricant reinforcement phase, according to the molar ratio of Ni:Al:Cr:Mo:Zr:B=4.5:1:0.333:0.243:0.0047:0.0015, weigh 7.952 grams of Ni powder, 0.81 grams of Al powder, 0.523 grams of Cr powder, 0.702 gram of Mo powder, 0.013 gram of Zr powder and 0.0005 gram o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com