Wear-resisting self-lubricating nylon carbon fiber composite material and preparation method thereof

A technology of nylon carbon fiber and composite materials, which is applied in the field of wear-resistant self-lubricating nylon carbon fiber composite materials and its preparation, can solve the problems of physical and mechanical properties, low cost performance, poor material processing performance, etc., and achieve excellent tribological properties and compatibility The effect of performance number and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] After premixing 58kg of PA6 210, 11kg of PTFE, 0.2kg of CV202, 0.6kg of TAF-A, 0.1kg of antioxidant 1010 and 0.1kg of antioxidant 168 in a high mixer, from the main feed Add it into a screw extruder, add 30kg of short carbon fibers from the side feed, heat and melt, extrude and pelletize after water cooling to obtain the wear-resistant self-lubricating nylon carbon fiber composite material of the present invention.

[0018] The temperature of each section of the twin-screw extruder is 160°C, 260°C, 250°C, 240°C, 230°C, 220°C, 220°C, 220°C, 220°C, 220°C, 230°C from the feeding port to the die head. ℃; the speed is 350~400r / min.

Embodiment 2

[0020] After premixing 70kg of PA6 210, 16kg of PTFE, 1kg of CV202, 1.0kg of TAF-A, 0.3kg of antioxidant 1010 and 0.3kg of antioxidant 168 in a high mixer, add it from the main feed In the screw extruder, add 35kg of short carbon fibers from the side feed, heat and melt, extrude and pelletize after water cooling to obtain the wear-resistant self-lubricating nylon carbon fiber composite material of the present invention.

[0021] The temperature of each section of the twin-screw extruder is 160°C, 260°C, 250°C, 240°C, 230°C, 220°C, 220°C, 220°C, 220°C, 220°C, 230°C from the feeding port to the die head. ℃; the speed is 350~400r / min.

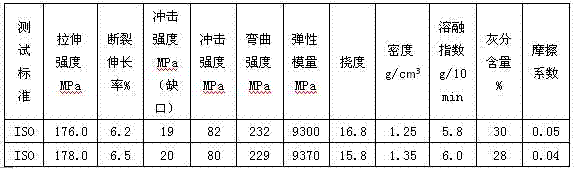

[0022] performance evaluation

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com