Blade perforated small axial fan

A technology for axial flow fans and blades, which is applied in the field of small axial flow fans with perforated blades, which can solve the problems of increased aerodynamic noise radiation and instability of fan blade lift force fluctuations, etc., to improve aerodynamic performance, overcome instability, and reduce turbulence. The effect of stream strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

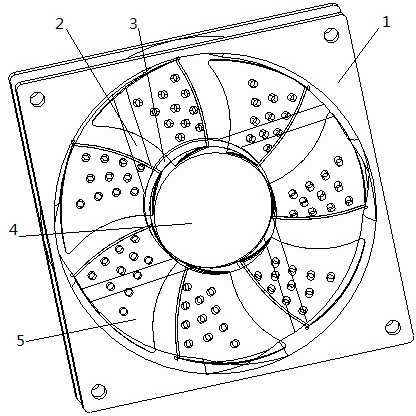

[0014] like figure 1 As shown, a small axial flow fan with perforated blades includes a case 1, a motor fixing frame 2, a motor 3, a hub 4, and perforated blades 5. The perforated blades 5 are installed on the hub 4 at equal intervals along the circumference, and the hub 4 rotates The shaft is connected with the motor 3, the motor 3 is fixed on the motor fixing frame 2, and the motor fixing frame 2 is fixed in the casing 1.

[0015] There are three rows of round holes on the perforated blade 5, each row of round holes is 4, 3, and 4 respectively, and the distribution area of the round holes is located in the area where the pressure on the pressure surface of the fan is higher and the pressure on the suction surface is lower, and The first row of round holes is in front of the separation point, the ratio of the diameter D of the round holes to the distance L between two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com