Optical fiber vector vibration sensor

A sensor and optical fiber technology, which is applied in the field of orthogonally polarized optical fiber vector vibration sensors, can solve problems such as hidden dangers, safety, and electronic devices that are prone to electric sparks, etc., and achieve the effect of simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

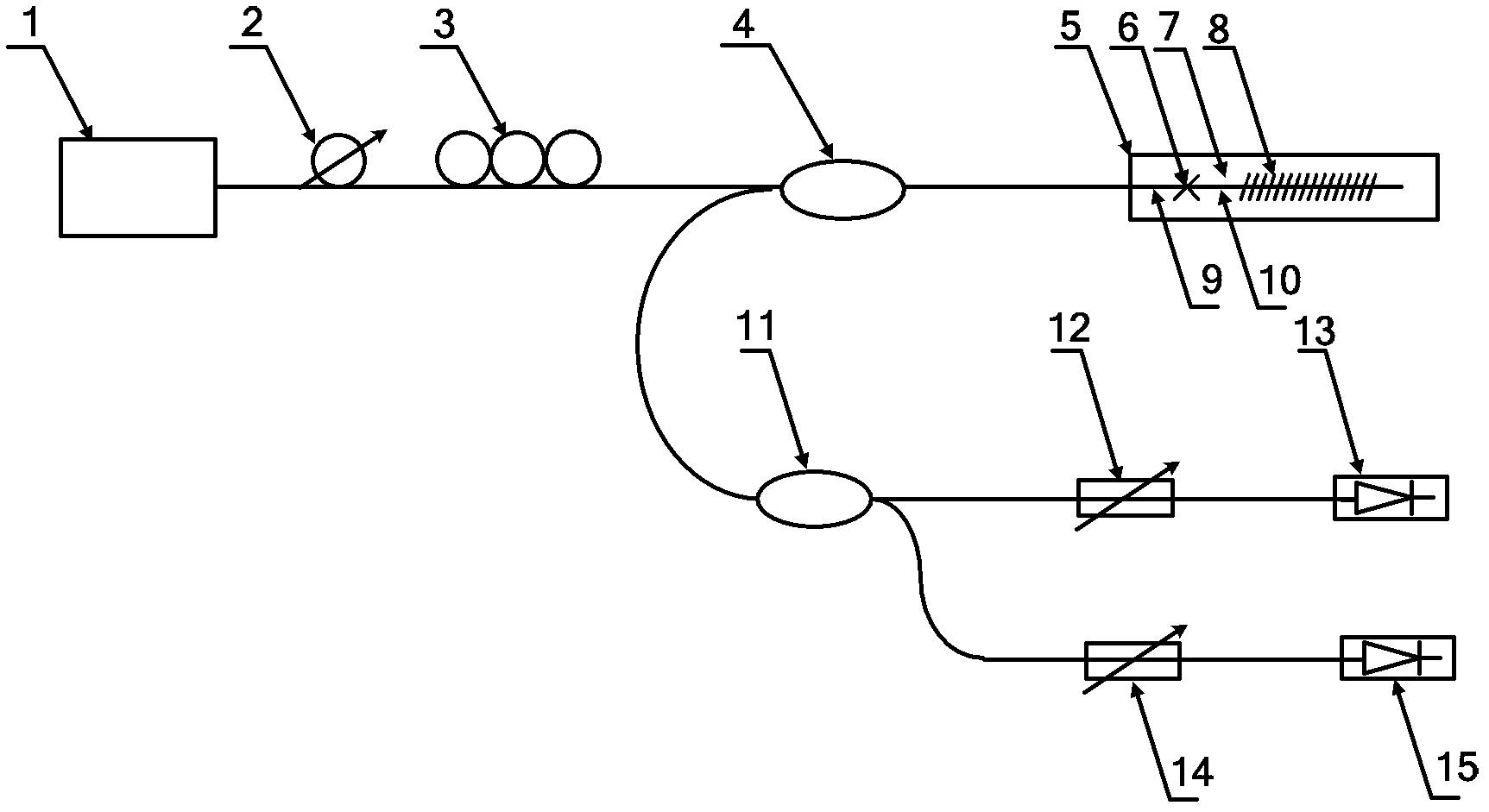

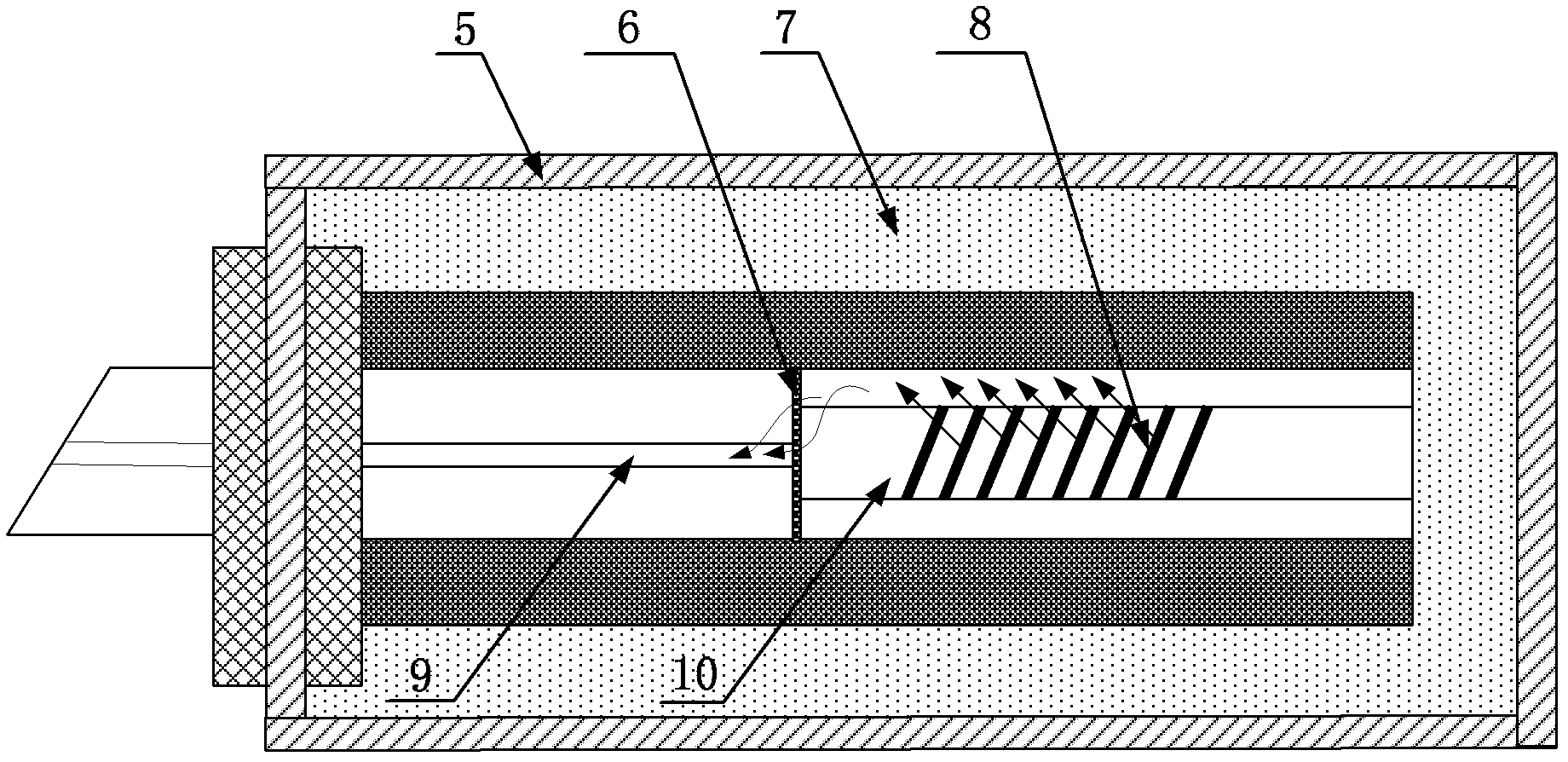

[0029] like figure 1 and 2 As shown, the optical fiber vector vibration sensor includes a broadband light source 1, a polarization control unit, a sensing probe and an orthogonal polarization demodulation unit. The polarization control unit, the sensing probe and the orthogonal polarization demodulation unit pass through the fiber The circulator 4 is connected; the polarization control unit includes a polarizer 2 and a polarization controller 3, and the broadband light source 1, the polarizer 2 and the polarization controller 3 are connected in sequence; the sensing probe includes a support member, a housing, a polymer An elastic tube 5, a fiber probe and an optical fiber lead 16, the fiber probe includes a multi-mode tilted fiber grating 8 and a cladding-core energy recoupling structure, the outer side of the polymer elastic tube 5 is protected by a casing, and the polymer elastic tube 5 One end is fixed on the support member, the other end is suspended in the air to sense v...

Embodiment 2

[0037] The structure of this embodiment is the same as that of Embodiment 1 except for the following features: the polarization control unit, the sensing probe and the orthogonal polarization demodulation unit are connected through a coupler.

[0038] The multi-mode tilted fiber grating 8 adopts a tilt angle grating with a tilt angle of 3 degrees.

[0039] The distance between the fusion point 6 where the multi-mode fiber segment 10 and the single-mode fiber segment 9 are fused and the multi-mode tilted fiber grating 8 is 3 mm.

Embodiment 3

[0041] The structure of this embodiment is the same as that of Embodiment 1 except for the following features: the multi-mode tilted fiber grating 8 adopts a tilt angle grating whose tilt angle is 1 degree.

[0042] The distance between the fusion point 6 where the multi-mode fiber segment 10 and the single-mode fiber segment 9 are fused and the multi-mode tilted fiber grating 8 is 4 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com