Method for extracting rim ultrasonic flaw detection signal on basis of wavelet transformation

A technology of wavelet transform and ultrasonic wave, which is applied in the field of extracting wheel rim ultrasonic flaw detection signal based on wavelet transform, to avoid false detection, improve signal-to-noise ratio, and achieve obvious effects of denoising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

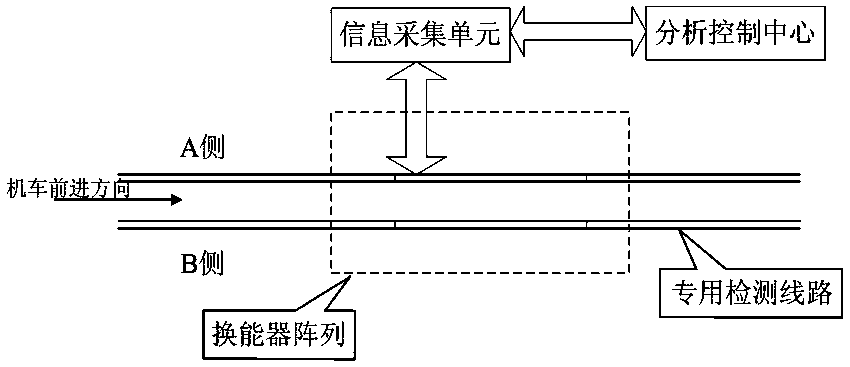

[0035] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing and example:

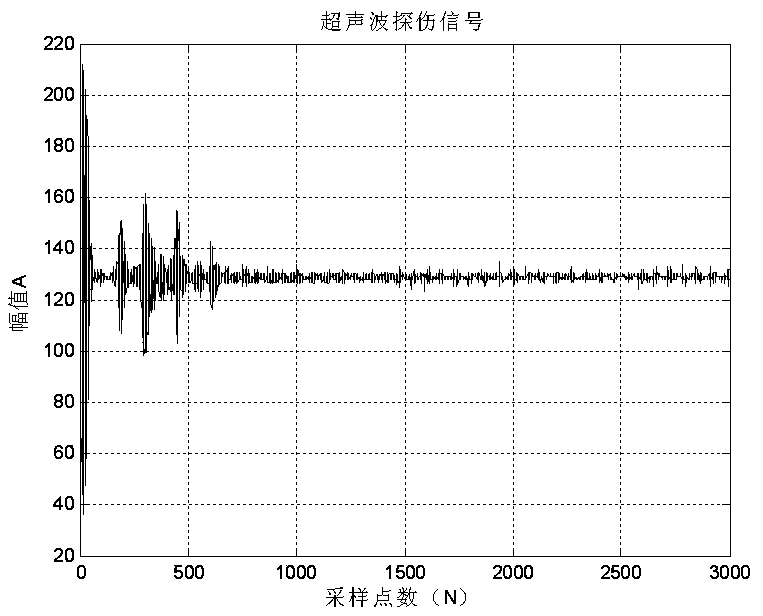

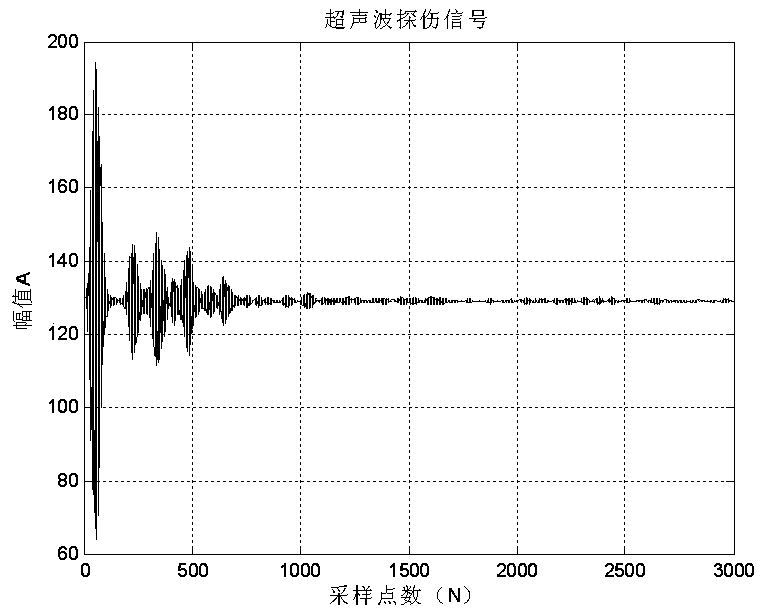

[0036] Looking at the five conventional non-destructive testing technologies in the industry, ultrasonic flaw detection has the most extensive application value and the highest frequency of use. However, when ultrasonic testing is performed on coarse-grained structures (such as locomotive rims, locomotive axles, etc.), the signal-to-noise ratio of the collected echo signals is small, and it is difficult to detect defect signals. Therefore, denoising the ultrasonic flaw detection signal is an important means to effectively extract the rim ultrasonic flaw detection signal.

[0037] 1. The denoising index of the present invention

[0038] In actual engineering, the use environment of online automatic flaw detection equipment for rims is very complicated. With the progress of the non-destructive testing process, various noises are inevitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com