Large unsaturated seepage physical simulator for soil in aerated zone

A technique of physical simulation and vadose zone, applied in soil material testing, material inspection products, etc., can solve the problem that the migration process has a large impact, cannot simulate the seepage and solute migration in unsaturated zones, and it is difficult to meet the boundary conditions of the model, etc. Problems, to achieve the effect of improving hands-on ability and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

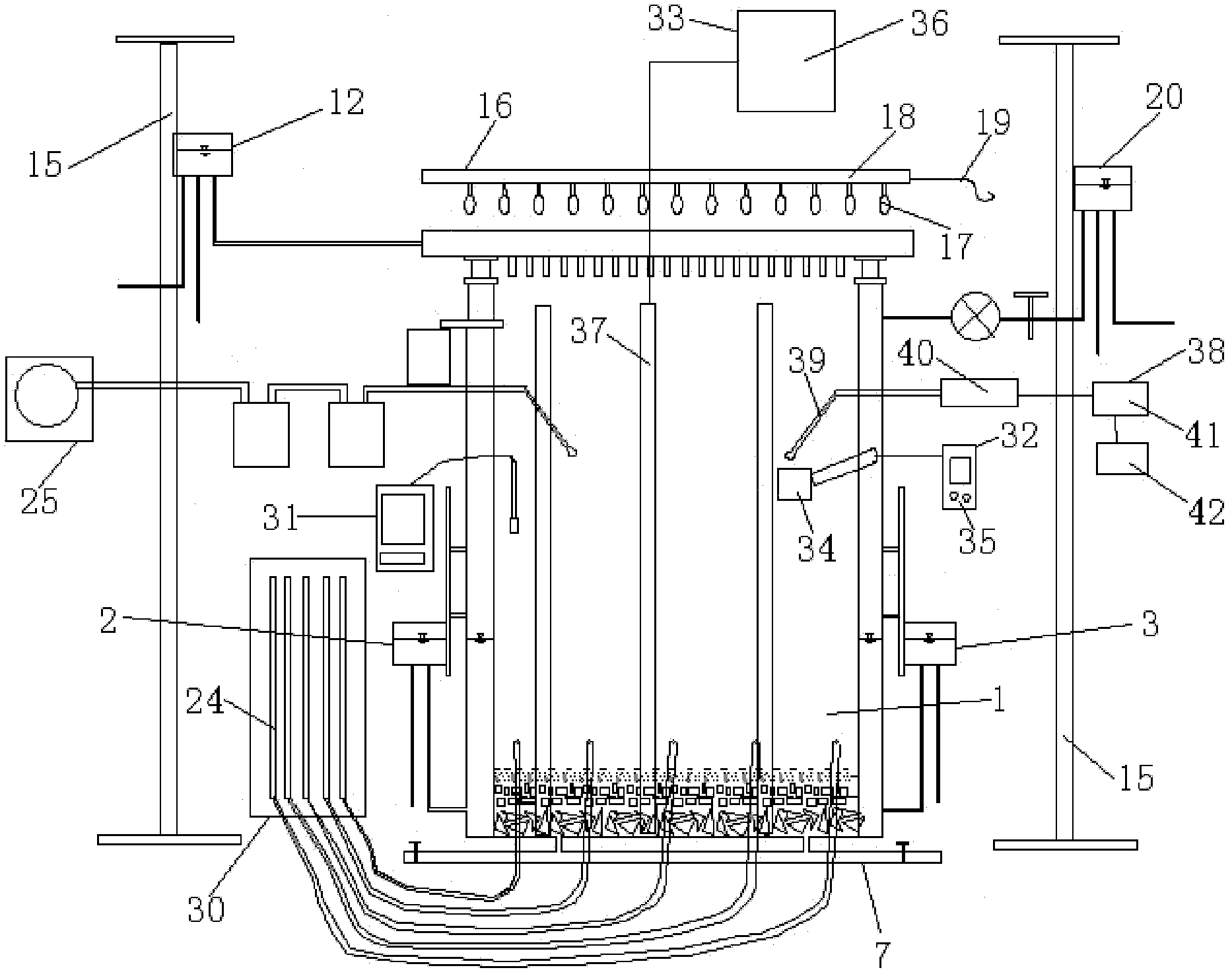

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

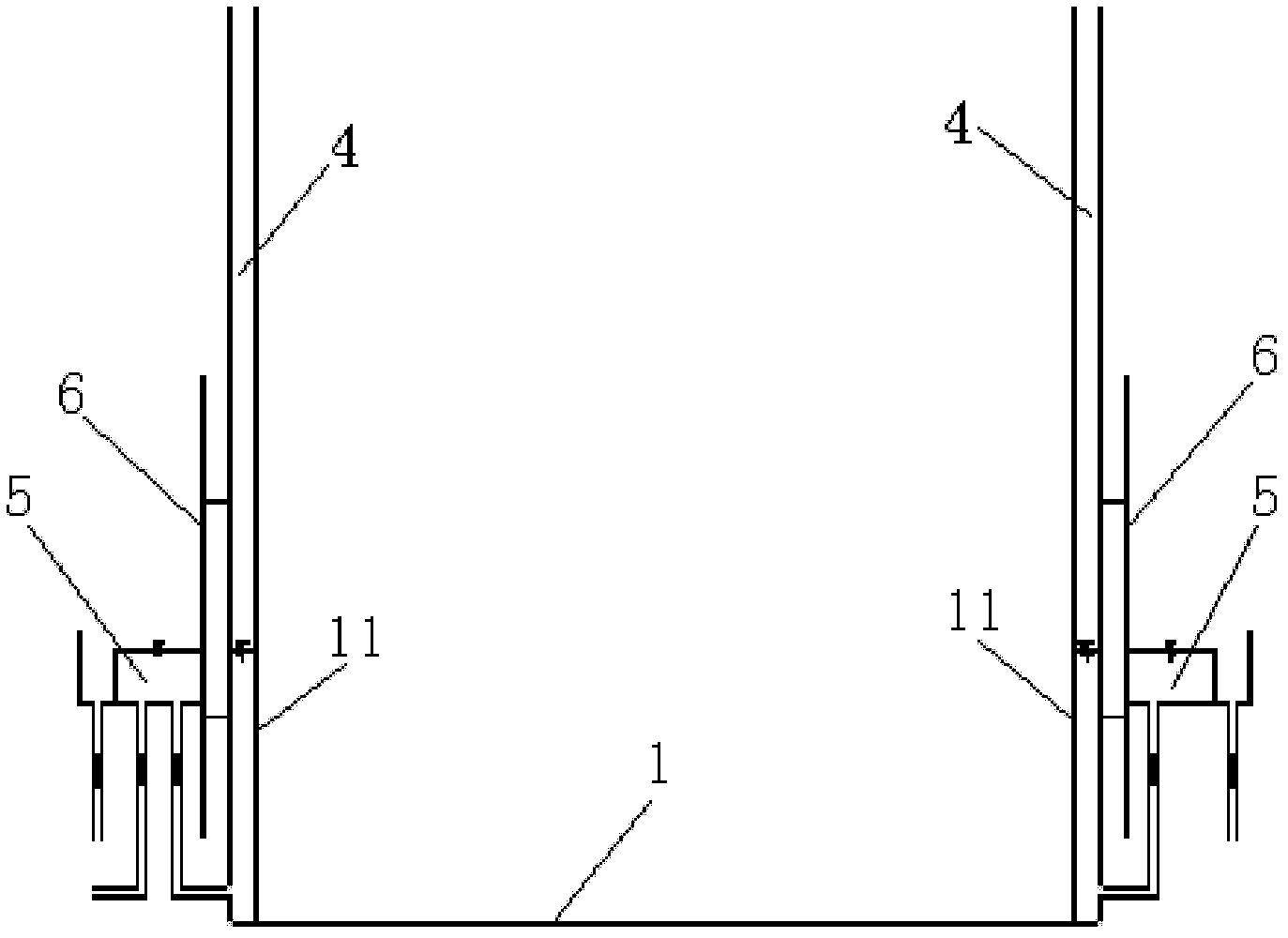

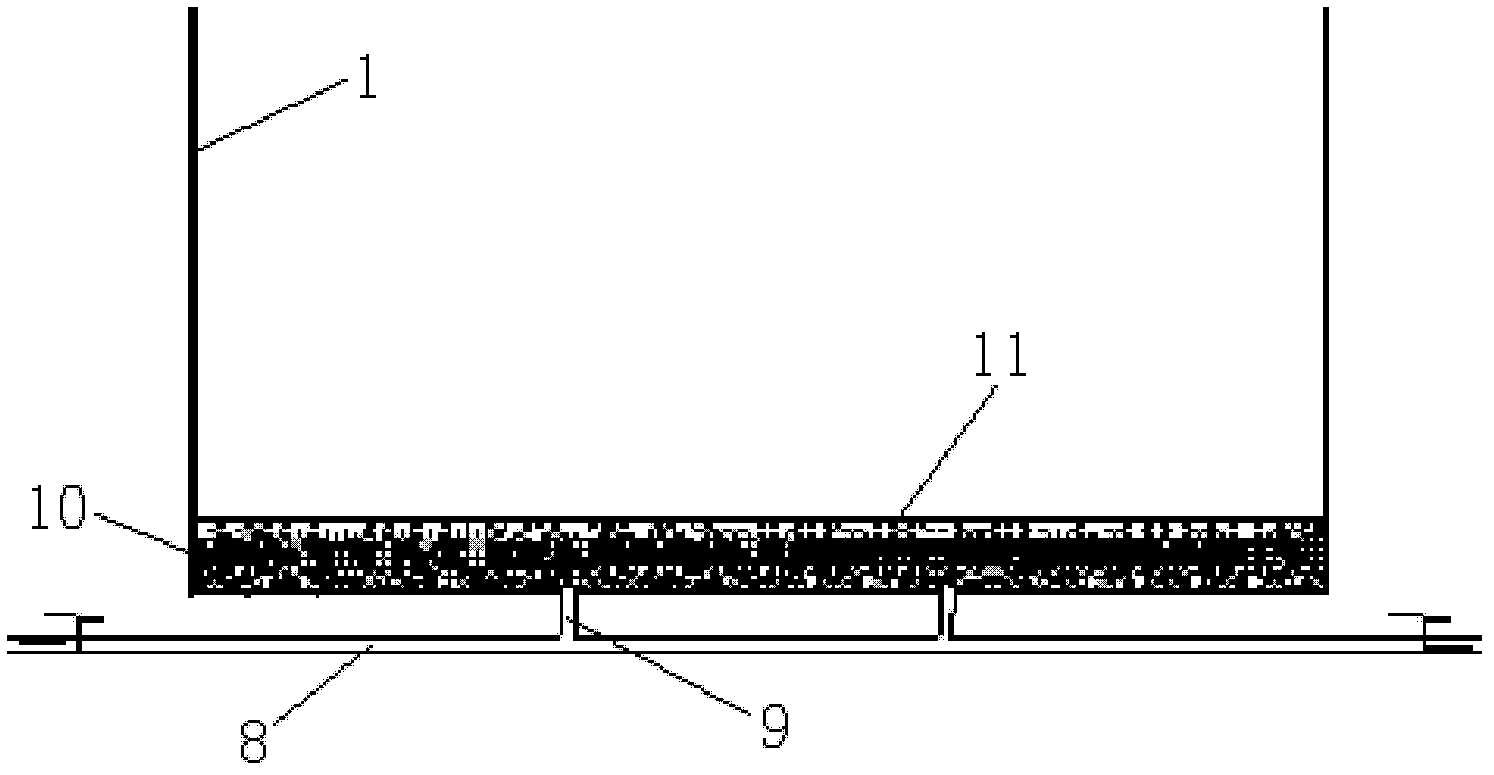

[0027] The schematic diagram of the overall structure of the large-scale vadose zone soil unsaturated seepage physical simulation device provided by the present invention is as follows: figure 1 As shown, it includes at least the test soil tank 1, the supplementary drainage system and the measurement system. The test soil tank 1 is in the shape of a cuboid and is welded by 0.5cm thick iron plates. The length, width and height of the cuboid-shaped test soil tank are respectively 3m, 1m, 4m. The test soil tank 1 is filled with test soil. The test medium is loose sediment from the floodplain of the Yangtze River. The impurities in the test soil are screened out, and then the soil tank is loaded into layers and compacted. The thickness of each layer is 10-20 cm. The thickness is 3.6m.

[0028] The supplementary drainage system includes a lateral supplementary drainage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com