Integrated thin film photovoltaic module and manufacturing method thereof

A technology of photovoltaic modules and manufacturing methods, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effects of preventing pollution and oxidation, improving efficiency, and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0038] However, the embodiment of the present invention can be changed into other various forms, and the scope of the present invention is not limited to the embodiment described below. In order to explain more clearly, the image and size of the elements in the drawings can be enlarged. For the quotation marks in the drawings and the same constituent elements, even if they are marked on different drawings, they should be marked with the same quotation marks as much as possible. When describing the present invention, if it is considered that specific descriptions related to known functions or configurations may obscure the gist of the present invention, detailed descriptions will be omitted.

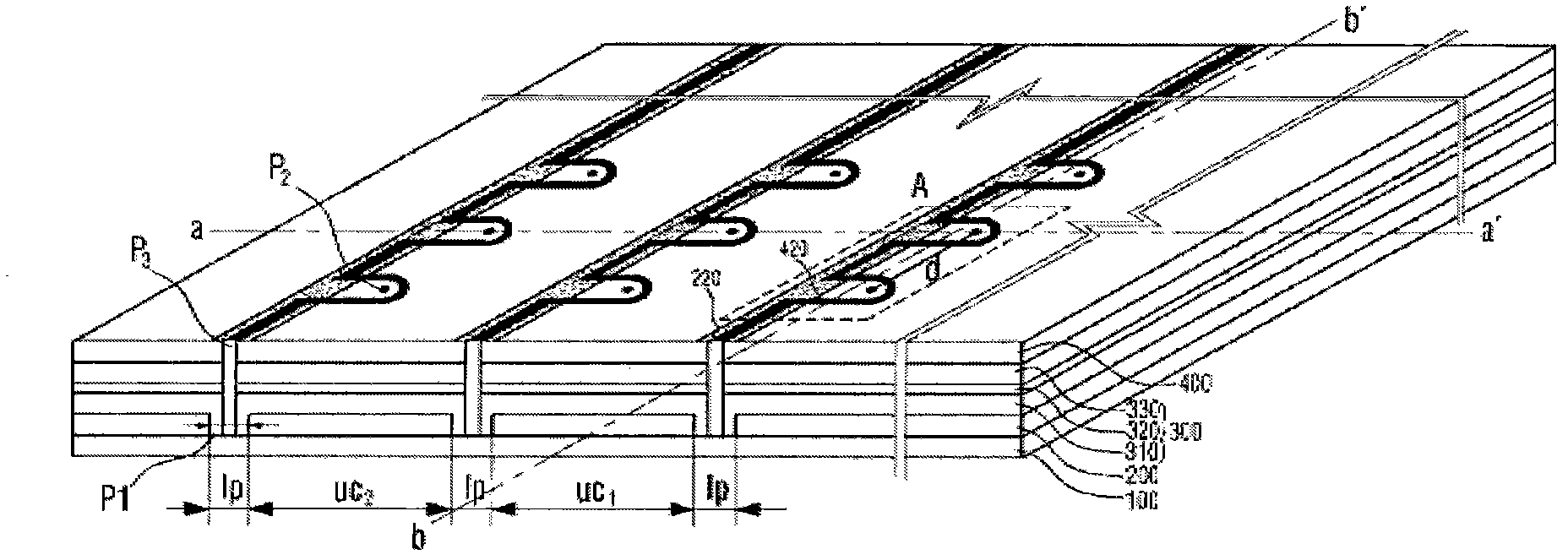

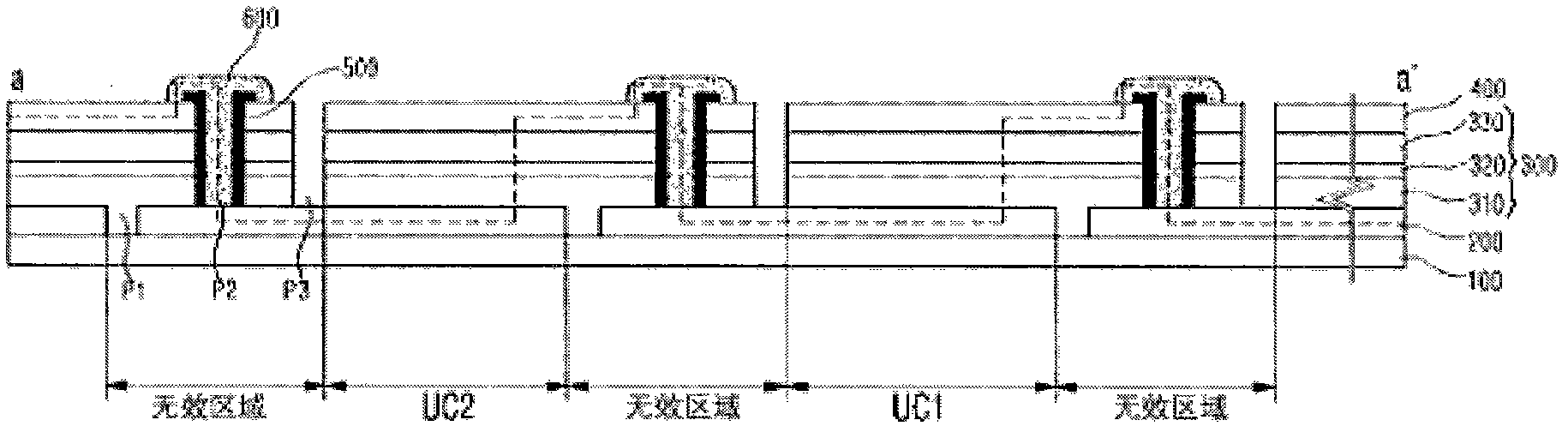

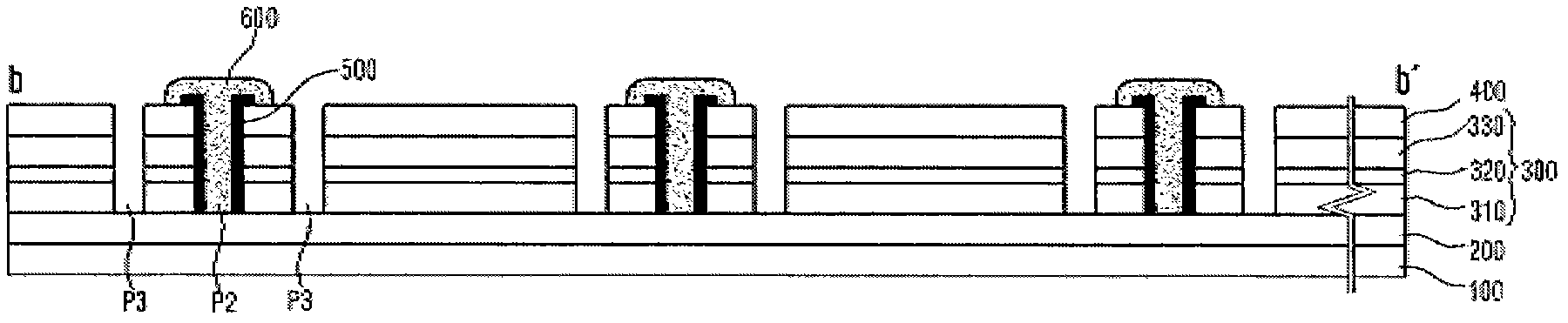

[0039] figure 1 is a schematic diagram of a photovoltaic module including photovoltaic cells connected in series through point contacts according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com