Bulk carrier and bulk cargo barge

A technology for bulk ships and hulls, which is used in bulk cargo, ship construction, ship accessories, etc. to achieve effective mass transportation and improve operational efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

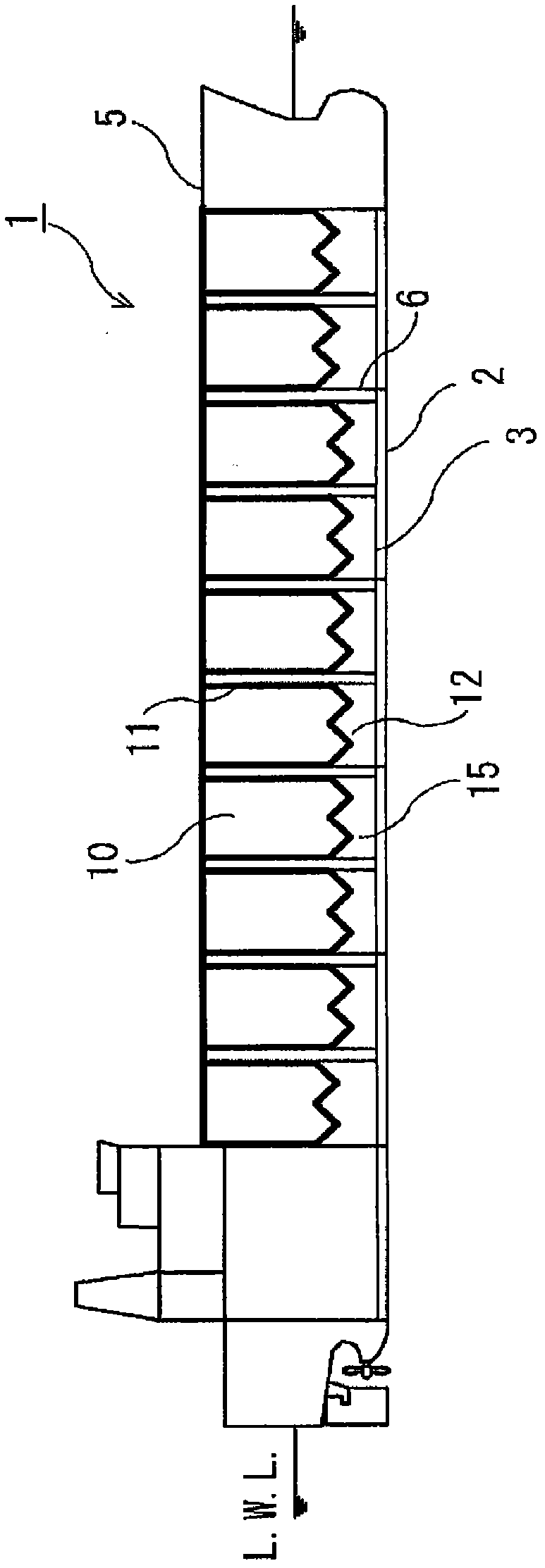

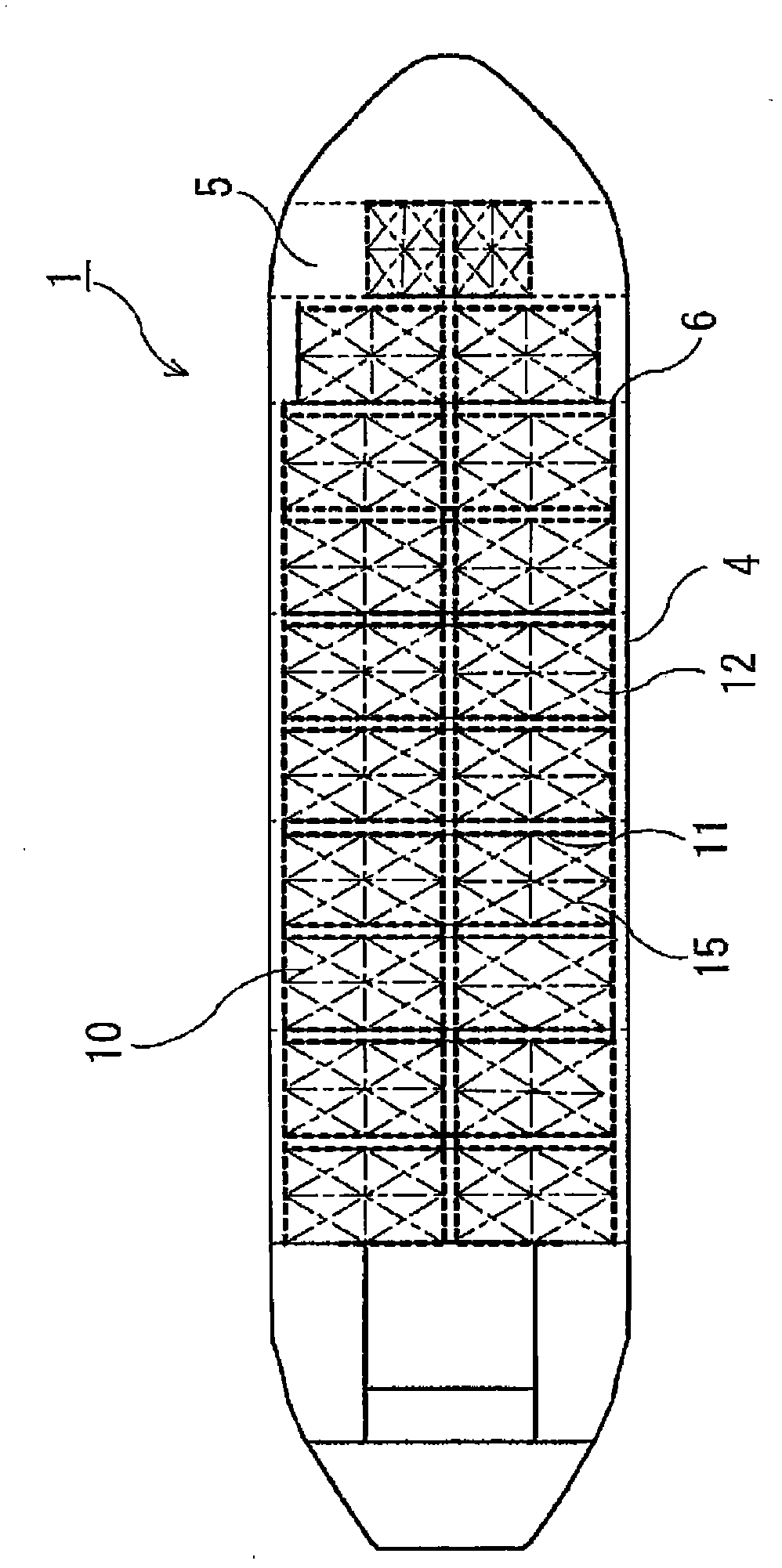

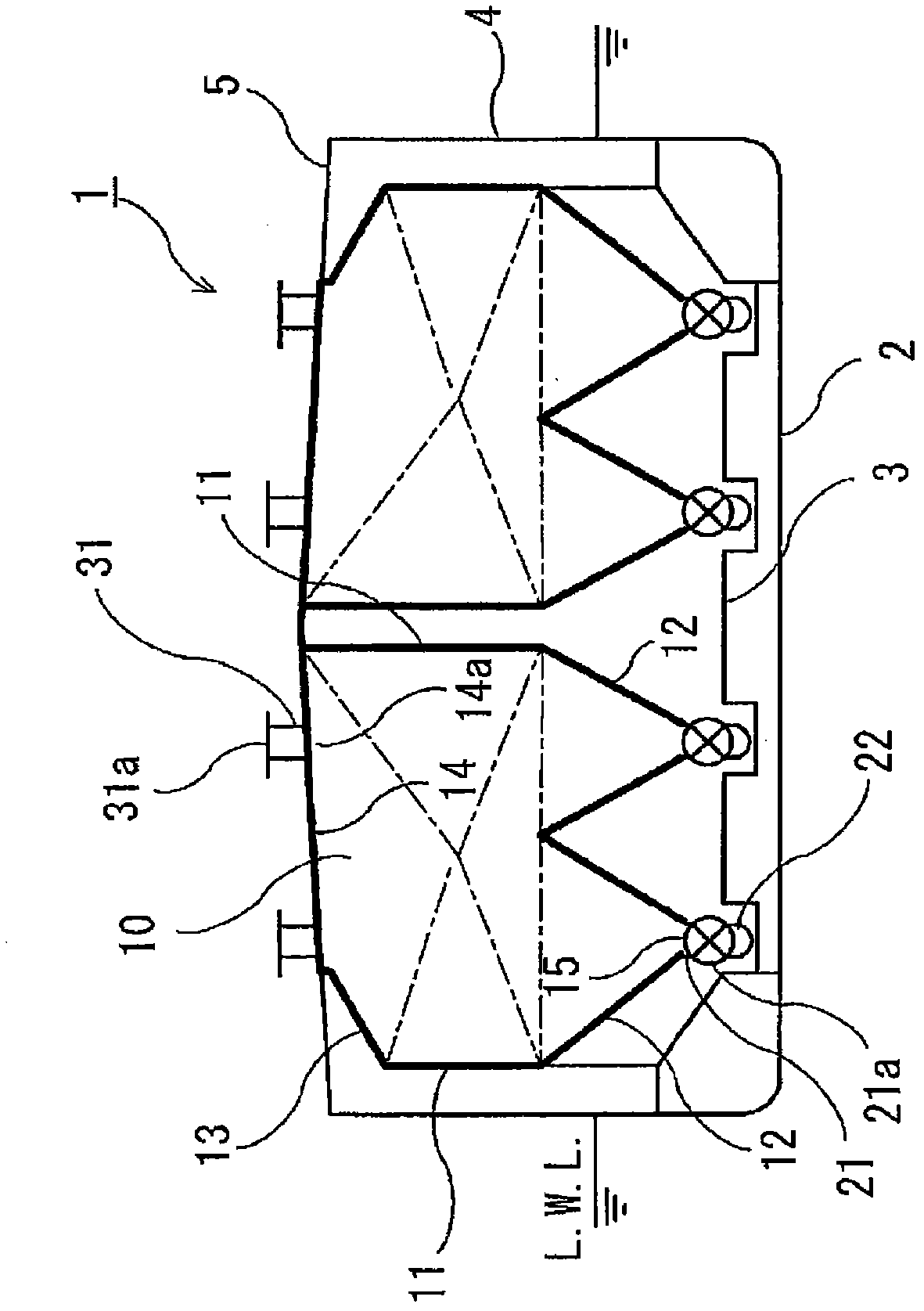

[0065] The bulk carrier and bulk barge of the present invention will be described below with reference to the accompanying drawings. A bulk carrier with propulsion is described here, but the invention is equally applicable to bulk barges without propulsion. In addition, the drawings are only for illustration, and are not necessarily drawn in accordance with the actual ship type or size ratio of the cargo hold. and Figure 9 It is also a diagram used to illustrate loading and unloading methods, and its hull structure is similar to that of Figure 1 to Figure 8 Compared with the hull structure of the ship, the shape of the cargo hold and the discharge port are different.

[0066] Such as Figure 1 ~ Figure 3 As shown, the bulk carrier 1 according to the first embodiment of the present invention includes a cargo hold 10 for loading bulk dry cargo. In this first embodiment, the cargo hold 10 is integrally formed with the hull. That is, the side walls 11 and the like of the ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap