Method for increasing bulk of reconstituted tobacco

A technology for reconstituted tobacco leaves and tobacco pine, applied in tobacco, tobacco preparation, application, etc., can solve the problems of poor thickness and uneven color of reconstituted tobacco leaves, and achieve the effect of increasing filling value, reasonable method and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

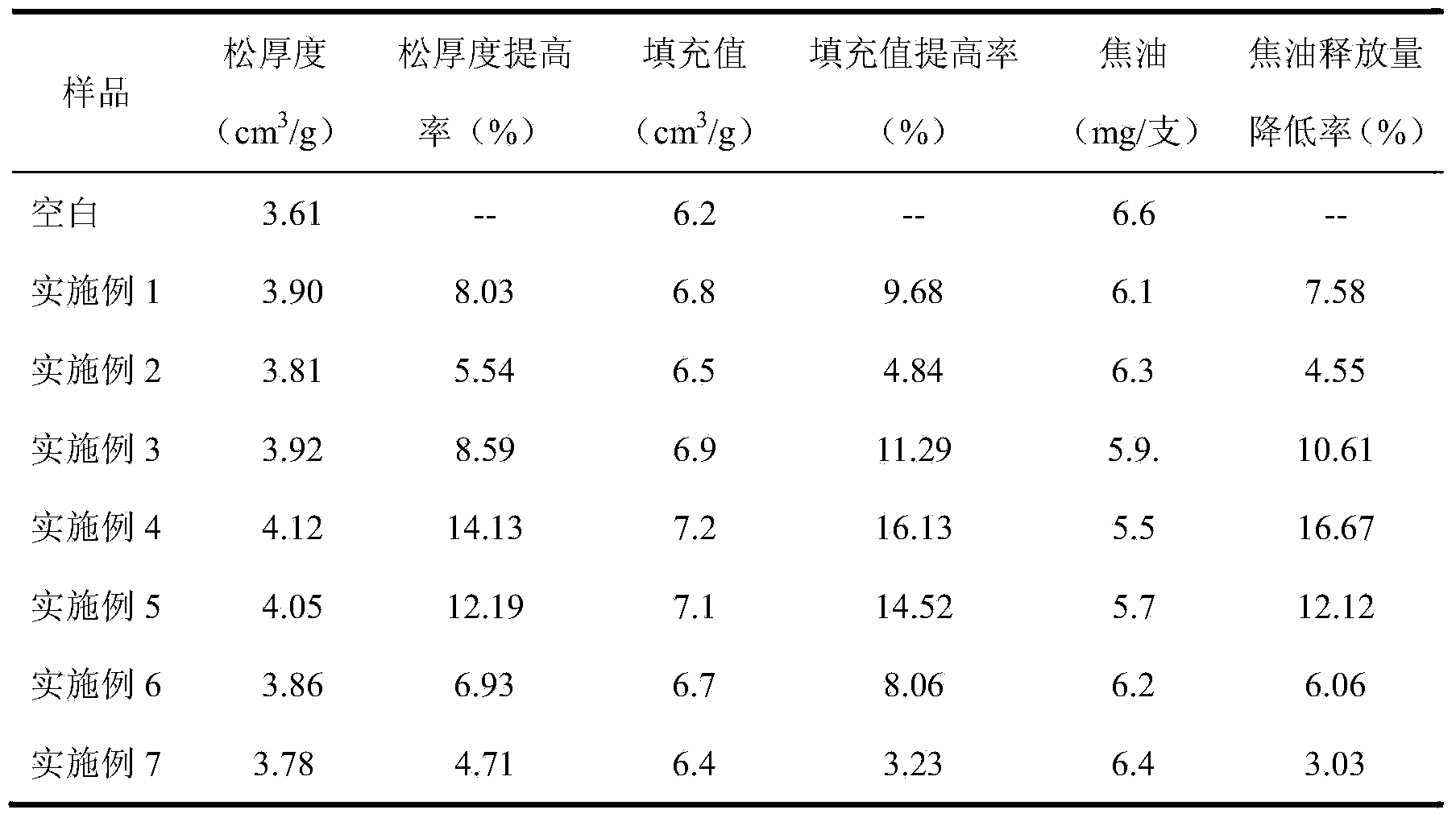

Examples

Embodiment 1

[0012] The mass percentage composition of additives: dry yeast powder 5%, fructose 15%, water 80%. In the tobacco raw material pulping stage of the reconstituted tobacco leaf preparation process, additives were added according to the ratio of 3% of the absolute dry mass of the tobacco pulp material, the temperature of the tobacco pulp was 30°C, and the treatment time was controlled at 40 minutes. The preparation method of the additive is as follows: dissolve the dry yeast powder in water at 32° C., place it for 6 minutes, add carbohydrates and mix evenly.

Embodiment 2

[0014] The mass percentage composition of the additive: dry yeast powder 20%, glucose 20%, water 60%. In the tobacco raw material pulping stage of the reconstituted tobacco leaf preparation process, additives were added according to the ratio of 10% of the absolute dry mass of the tobacco pulp material, the temperature of the tobacco pulp was 35°C, and the treatment time was controlled at 80 minutes. The preparation method of the additive is as follows: dissolve the dry yeast powder in water at 35° C., place it for 10 minutes, add carbohydrates and mix evenly.

Embodiment 3

[0016] The mass percentage composition of additives: dry yeast powder 10%, maltose 25%, water 65%. In the tobacco raw material pulping stage of the reconstituted tobacco leaf preparation process, additives were added according to the ratio of 8% of the absolute dry mass of the tobacco pulp material, the temperature of the tobacco pulp was 25°C, and the treatment time was controlled at 55 minutes. The preparation method of the additive is as follows: dissolve the dry yeast powder in water at 30° C., place it for 5 minutes, add carbohydrates and mix evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com