Thick-walled tube saddle port cutting mould, and formation method and application method thereof

A technology of thick-walled pipe and saddle mouth, which is applied in the field of cutting molds for thick-walled pipe saddle mouth, can solve the problems of not meeting the actual requirements of production costs, high price of CNC special-shaped cutting machines, and difficulty in meeting quality requirements, etc., and achieves Inexpensive to make, avoid overpriced, easy to implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

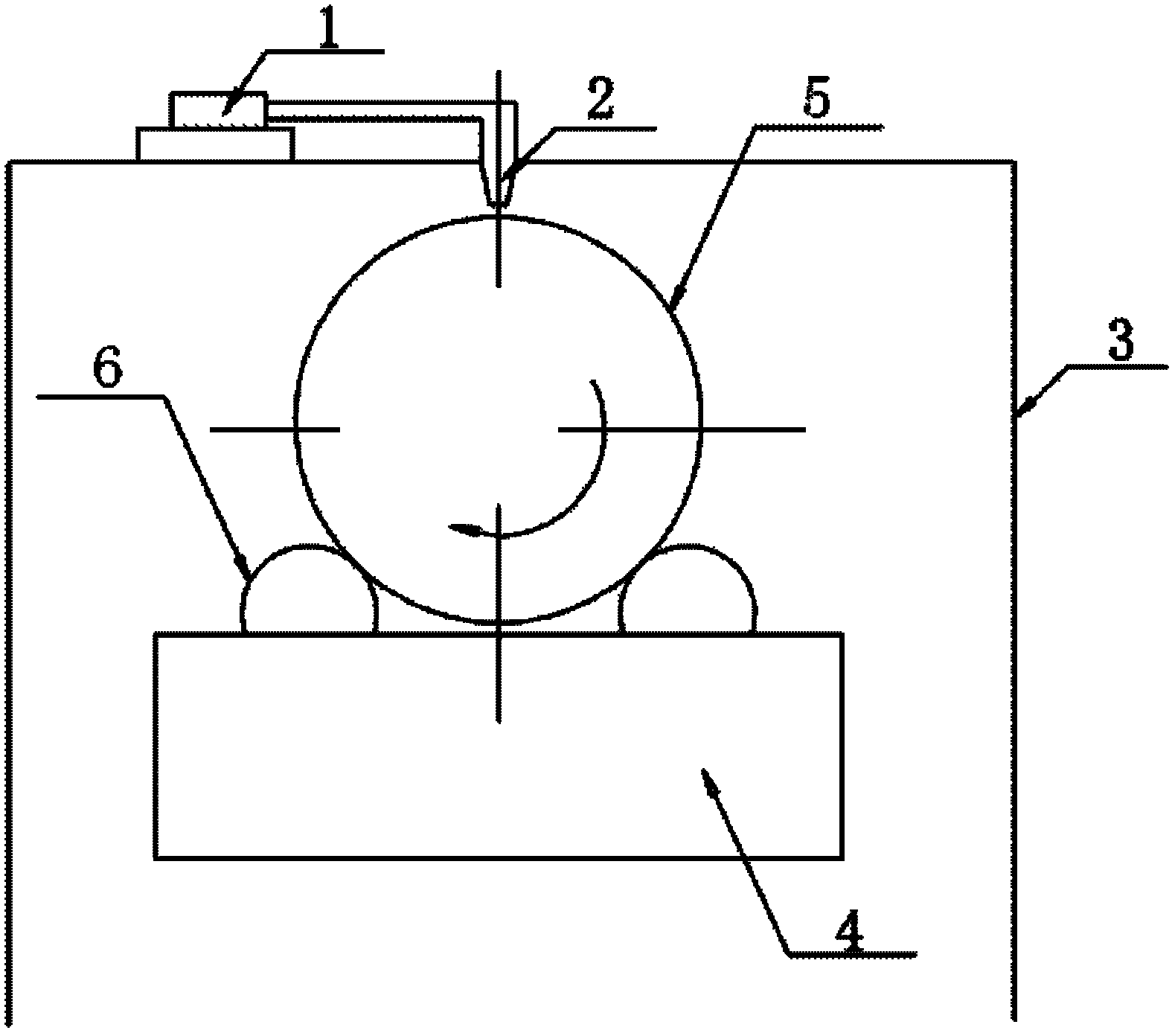

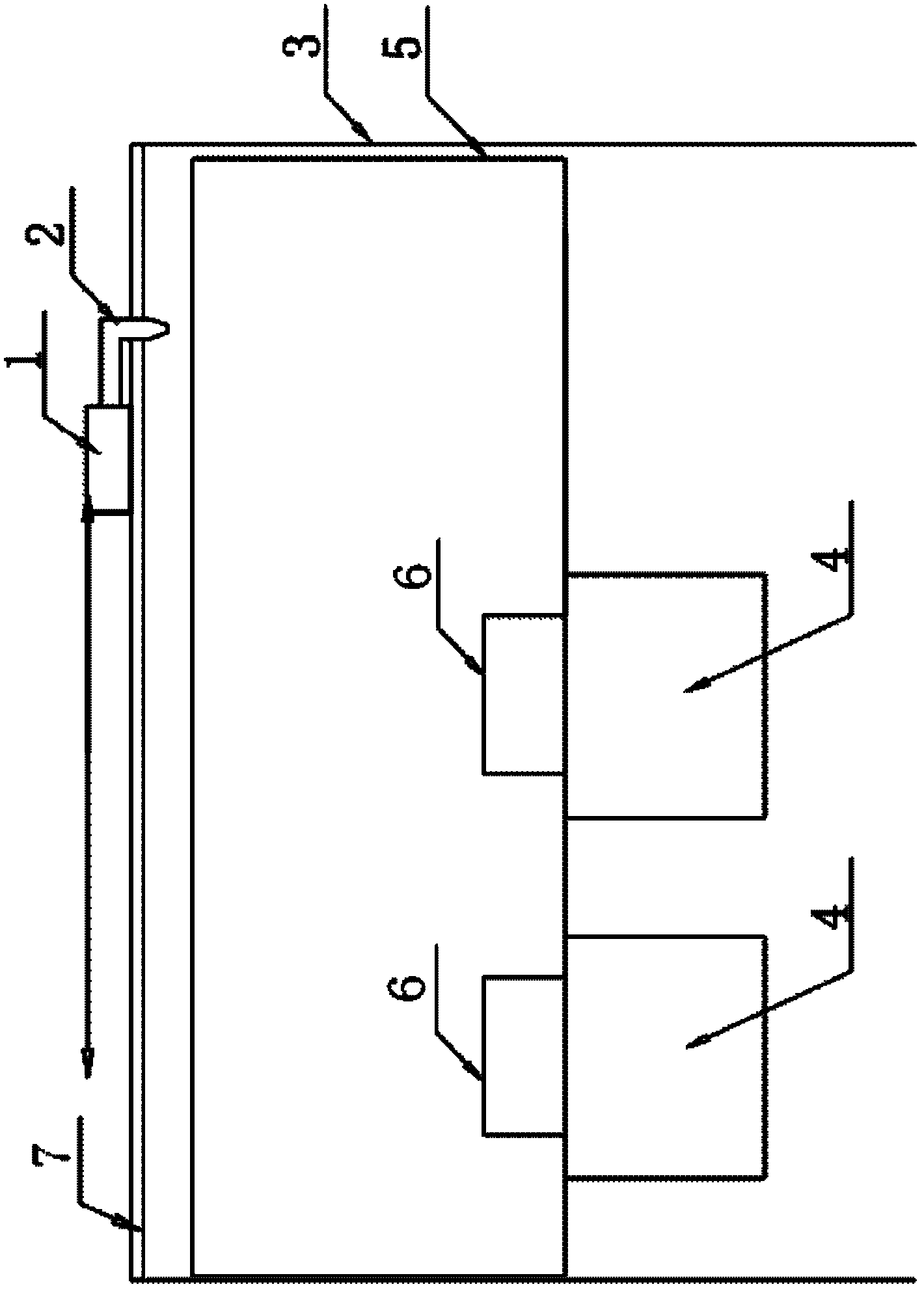

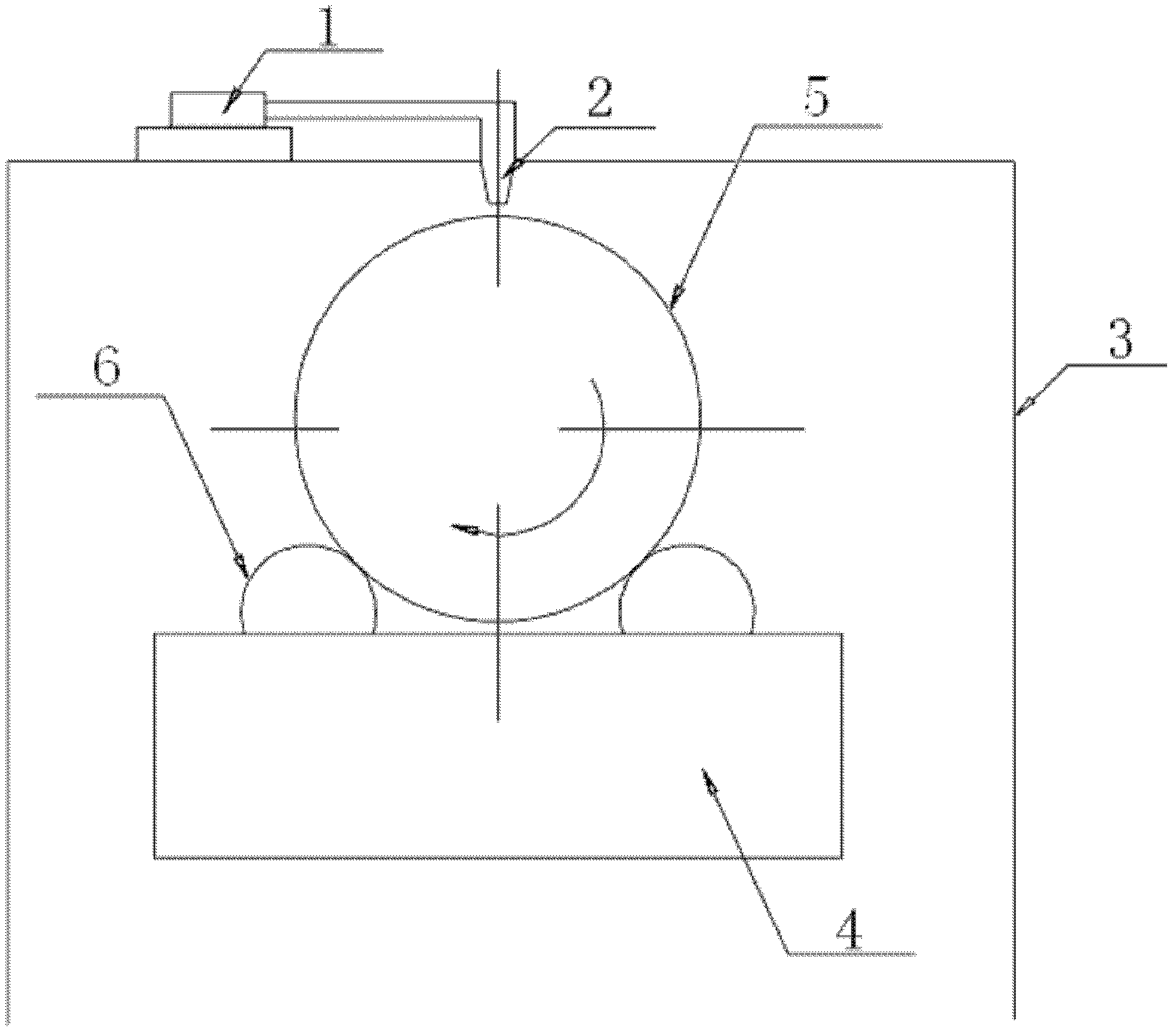

[0027] refer to figure 1 , figure 2 , the thick-walled pipe saddle mouth cutting mold of the present invention includes a door-shaped support platform 3, a trolley track 7 is arranged on the support platform 3, and a rotary tire 4 is arranged below the support platform 3. Two rollers 6 for holding up the thick-walled tube 5 and driving the thick-walled tube 5 to rotate are arranged on the rotating tire 4 in a center-symmetrical manner, and the semi-automatic cutting machine trolley 1 is arranged on the trolley track 7, The flame cutting nozzle 2 on the semi-automatic cutting machine trolley 1 is perpendicular to the pipe wall of the thick-walled pipe 5 .

[0028] The composition mode of the present invention and using method are as follows:

[0029] (1) Place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com