Control method for carburizing, quenching and deformation of thin wheel disk type large-diameter cylindrical gear

A cylindrical gear, carburizing and quenching technology, applied in the direction of heat treatment process control, manufacturing tools, coating, etc., can solve problems such as deformation, achieve the effect of ingenious conception, reduction of heating rate and cooling rate inconsistency, and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Example: A Control Method for Carburizing and Quenching Deformation of Thin Web Plate Large-diameter Cylindrical Gears

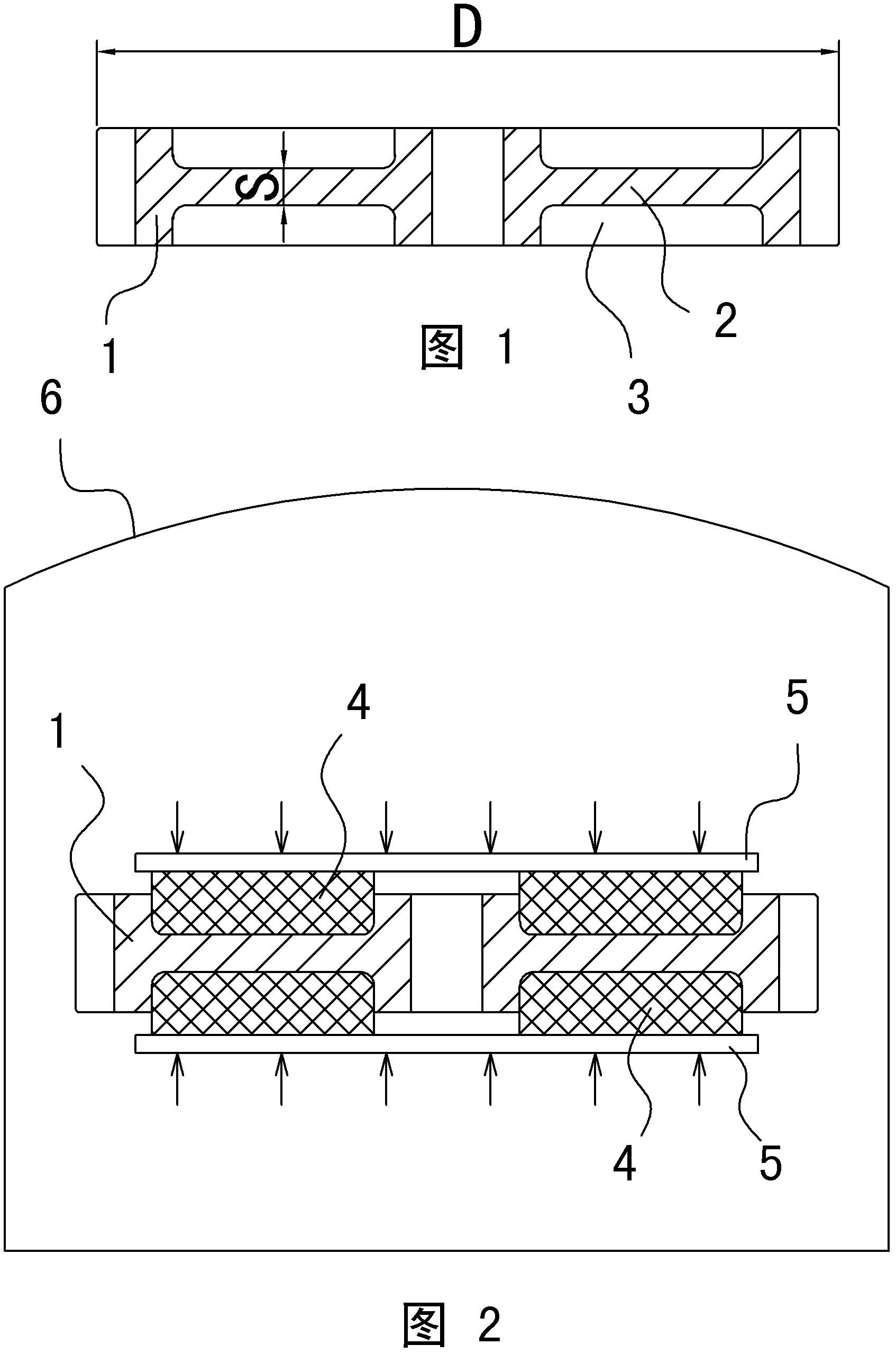

[0017] Such as figure 1 As shown, the cylindrical gear in this embodiment is a spur gear 1, the diameter D of the outer edge of the gear is between 1.2 and 1.7 meters, and the thickness S of the web 2 is between 150 and 250 mm.

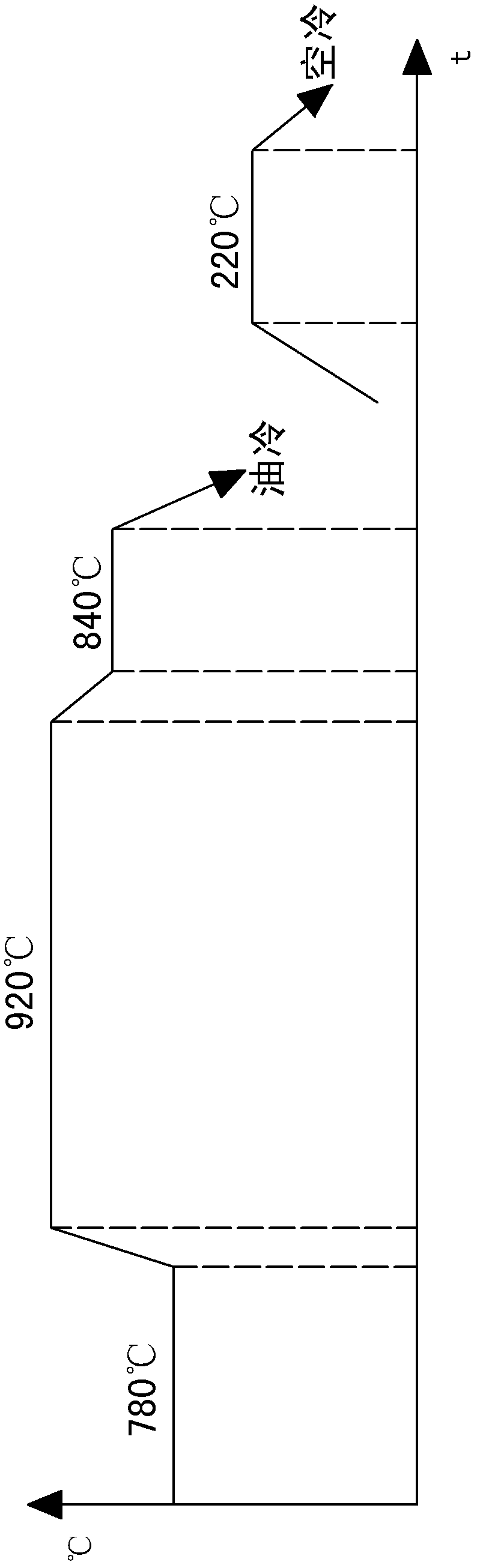

[0018] Such as figure 2 As shown, for this type of thin web-type large-diameter spur gear 1, before the carburizing and quenching starts, the aluminum silicate fiber material 4 is used to fill the corresponding concave parts 3 on both sides of the web 2 of the cylindrical gear 1, and A steel plate 5 is respectively arranged at both ends of the cylindrical gear 1, and the aluminum silicate fiber material 4 covering both sides of the web 2 of the cylindrical gear 1 is clamped and pressed by the two steel plates 5, so as to protect the web 2 of the cylindrical gear 1 part; then carry out carburizing and quenching heat treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com